Winding device and winding method of motor rotor iron core assembly

A technology for motor rotors and winding devices, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve problems such as low work efficiency, high labor intensity, unstable product quality, etc., to improve work efficiency, ensure product quality, Improving the effect of the winding method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

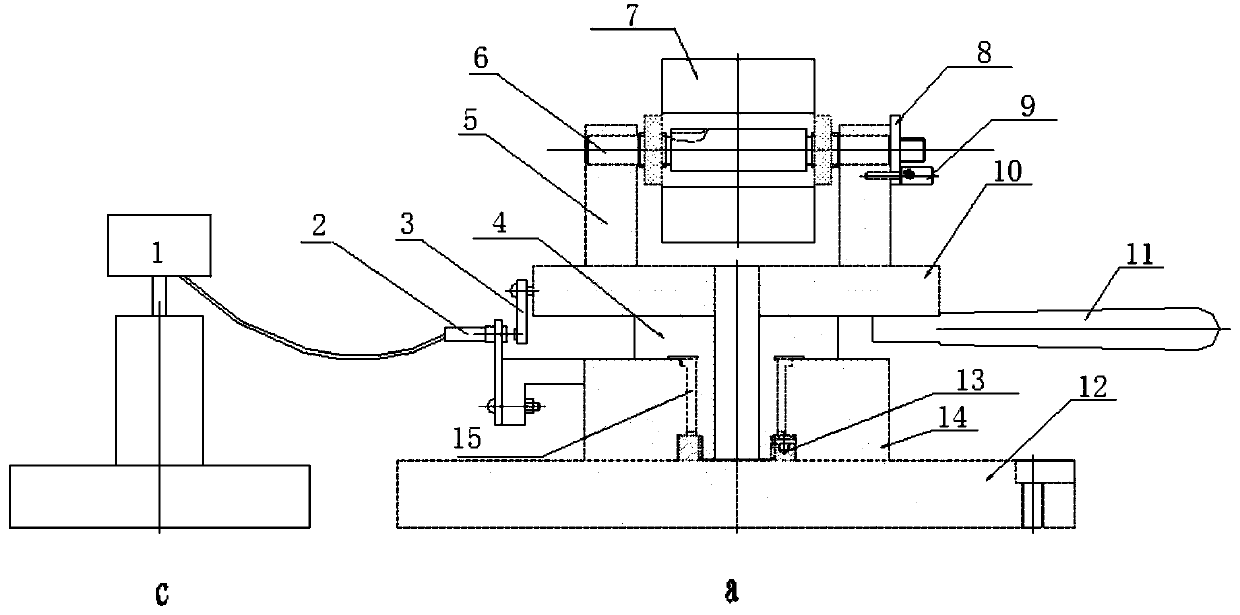

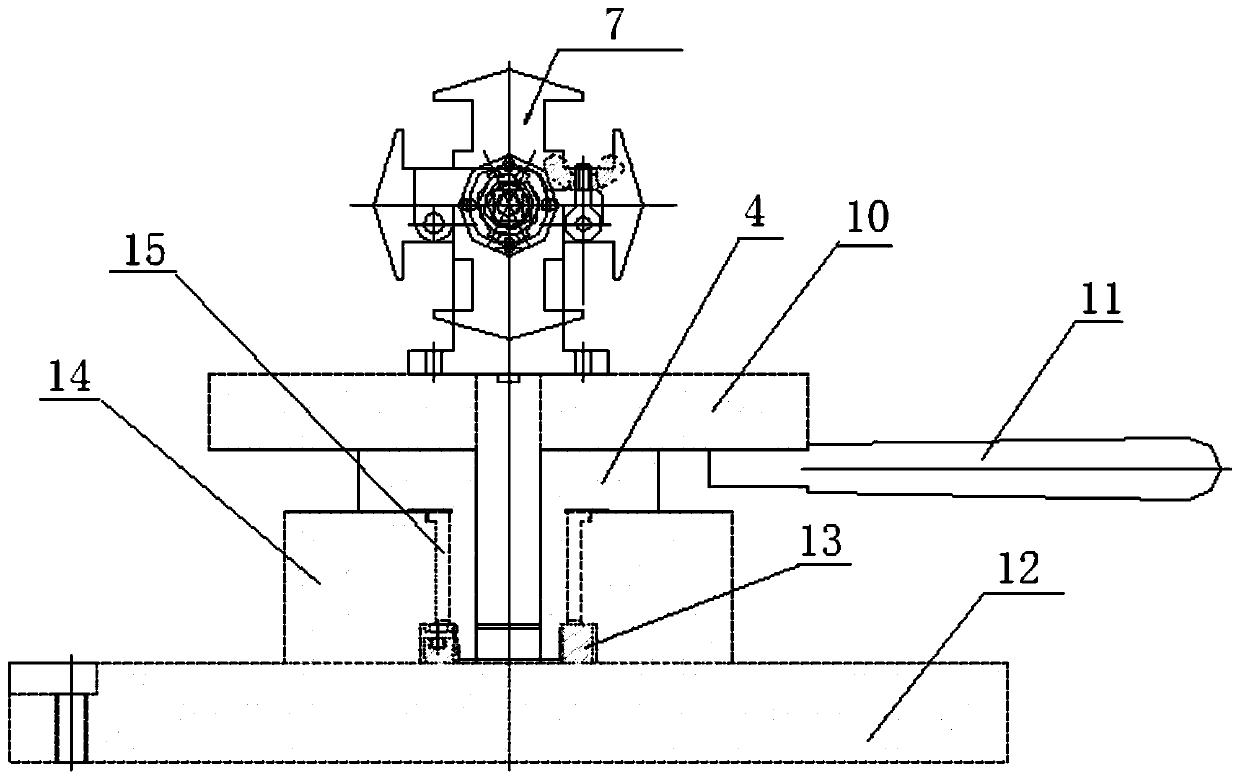

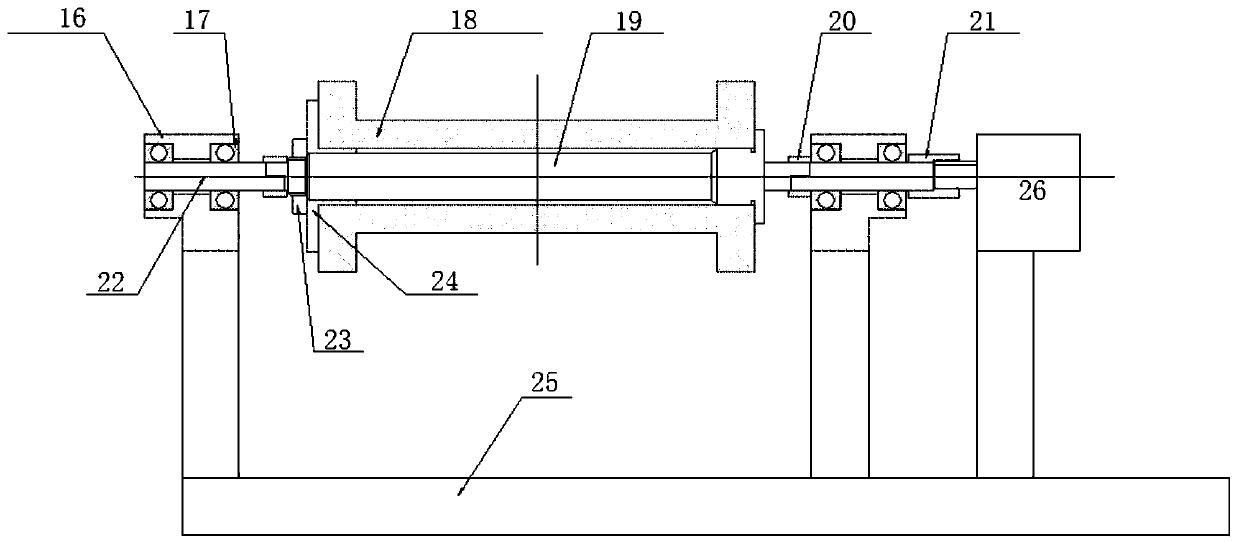

[0023] The present invention will be described in further detail below, the device includes a winding module see Figure 1-2 and supply modules see image 3 . Wherein, the winding module includes a bottom rotation unit and a top rotation unit, the bottom rotation unit can rotate around the vertical rotation axis 4, the top rotation unit is installed on the bottom rotation unit, and the top rotation unit has A horizontal rotating shaft 6 on which the rotor core 7 is mounted; the number of rotations of the bottom rotating unit is detected by a counter 1, and the rotation of the rotor core 7 is limited by a positioning pin 9; the The supply module has a damping force.

[0024] The bottom rotating unit comprises a seat plate 12 at the bottom, on which a rotating seat 14 with a through hole is fixed, and the vertical rotating shaft 4 is installed in the through hole of the rotating seat 14, and is connected with the rotating disk 10 at the top, and the A handle 11 is also connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com