Axial multi-magnetic-pole permanent magnet rotor brushless motor

A permanent magnet rotor, brushless motor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit, electric components, etc., can solve the problems of restricting the normal application of permanent magnets, the energy saving effect is not obvious, and the manufacturing process is complicated, so as to achieve the energy saving effect. Visible, lightweight and small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

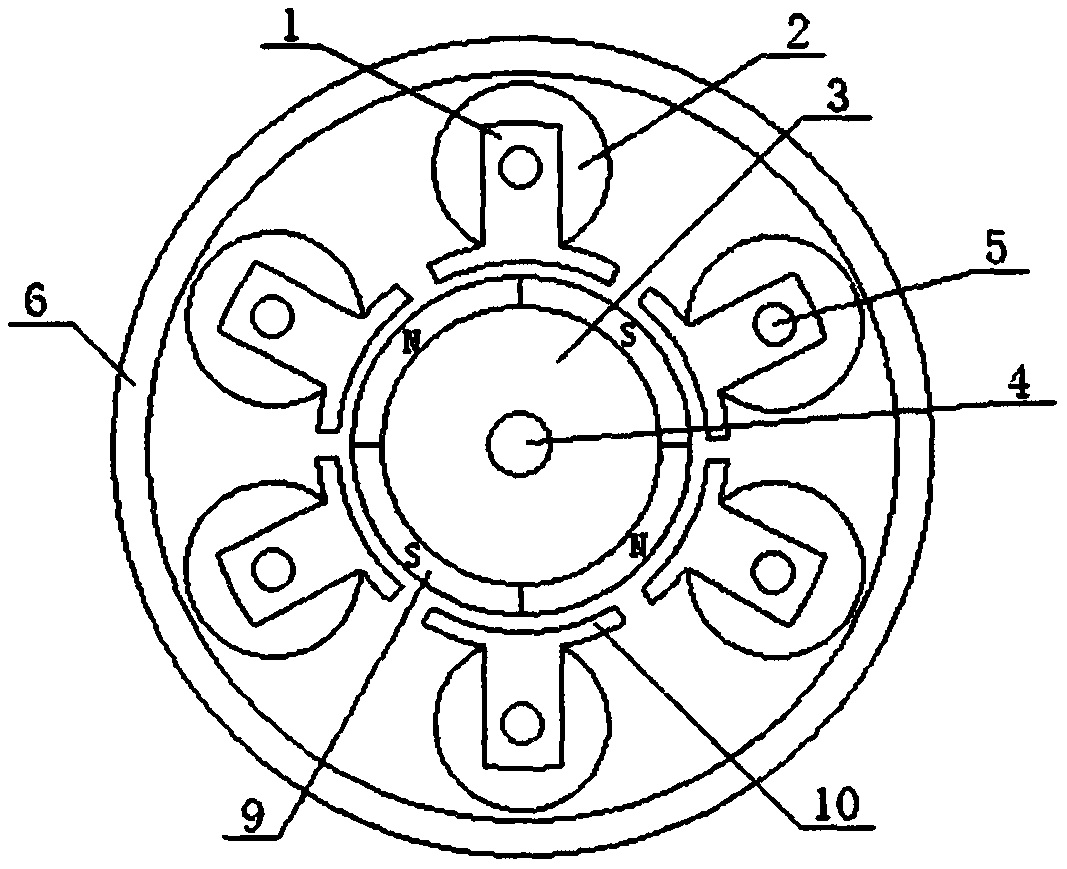

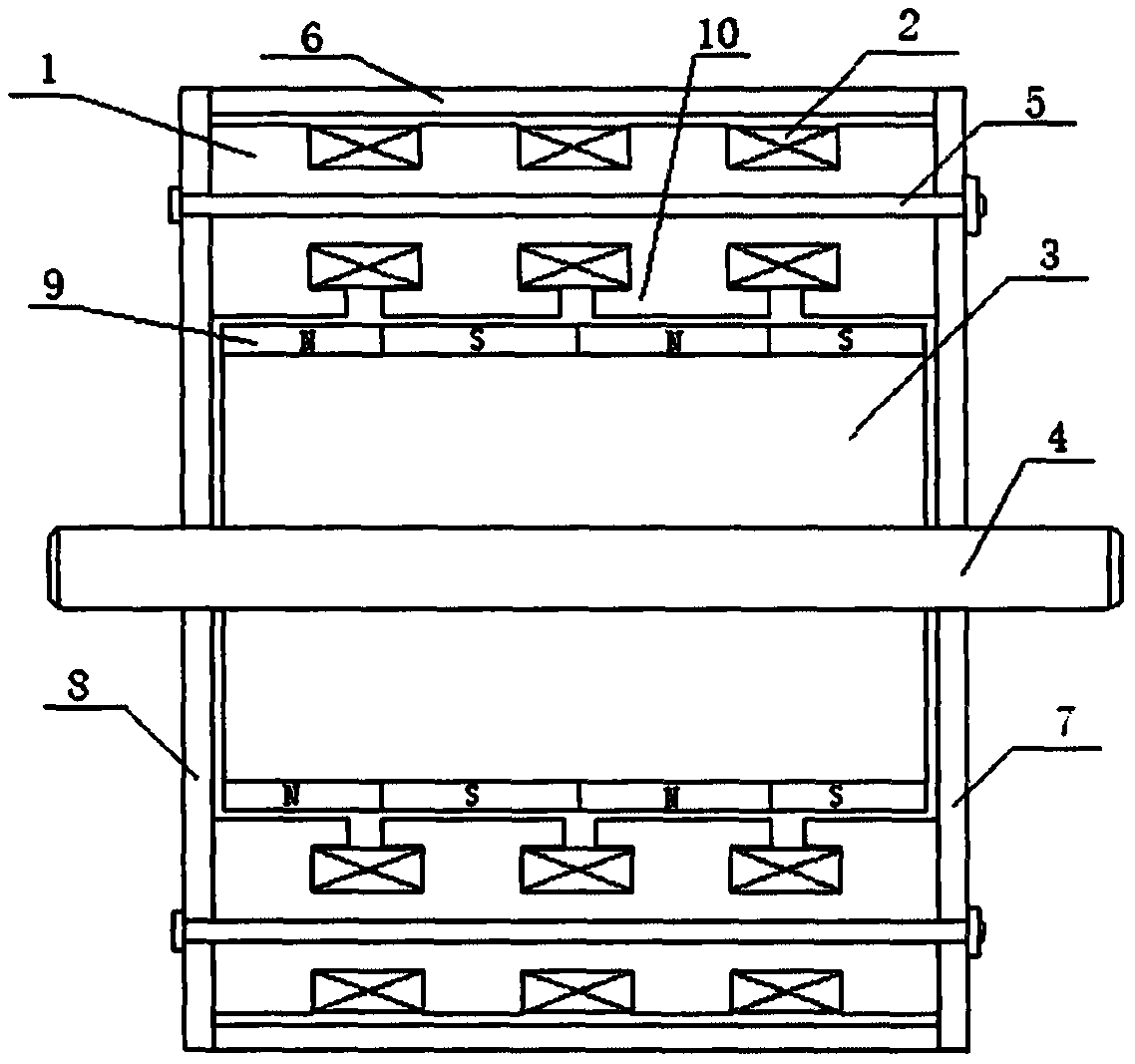

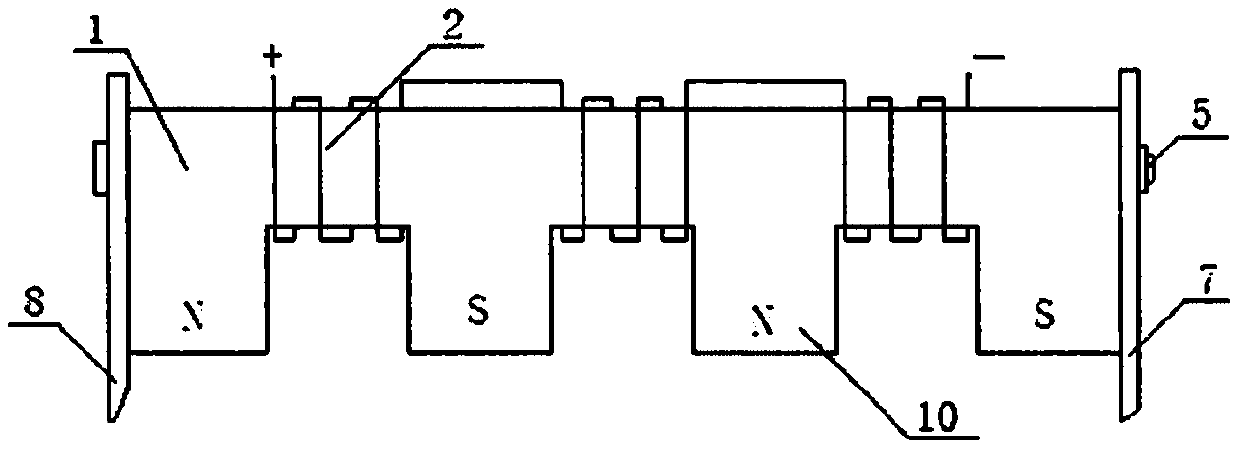

[0013] In order to deepen understanding of the present invention, below in conjunction with embodiment and appended figure 1 , 2 , 3, 4, to further describe the present invention in detail, this embodiment is only used to explain the present invention, and does not constitute a limitation to the protection scope of the present invention.

[0014] An axial multi-pole permanent magnet rotor brushless motor, comprising a rotor (3), a main shaft (4), a stator core (1), a casing (6), a first casing end cover (7), and a second casing end cover (8) Composition. The arc surface of the rotor (3) is fixed with magnetic tiles (9) arranged in sequence. The specifications of each magnetic tile are the same, and the magnetic poles are radial magnetic poles. The polarity of each adjacent magnetic tile is different, that is, N pole, S poles, N poles, S poles..., the number of magnetic tiles on the arc surface of the rotor (3) of the present embodiment is 16 (4 * 4), and its arrangement is 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com