Preparation method and application method of individualized compensation film

A technology for compensating film and body surface, applied in radiation therapy, X-ray/γ-ray/particle irradiation therapy, treatment and other directions, can solve the problems of material flexibility, poor uniformity, unsuitable and incorrect vertical parts, etc., to achieve shortening Recovery time, protection from damage, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate those skilled in the art to understand the technical content of the present invention, the content of the present invention will be further explained below in conjunction with the accompanying drawings.

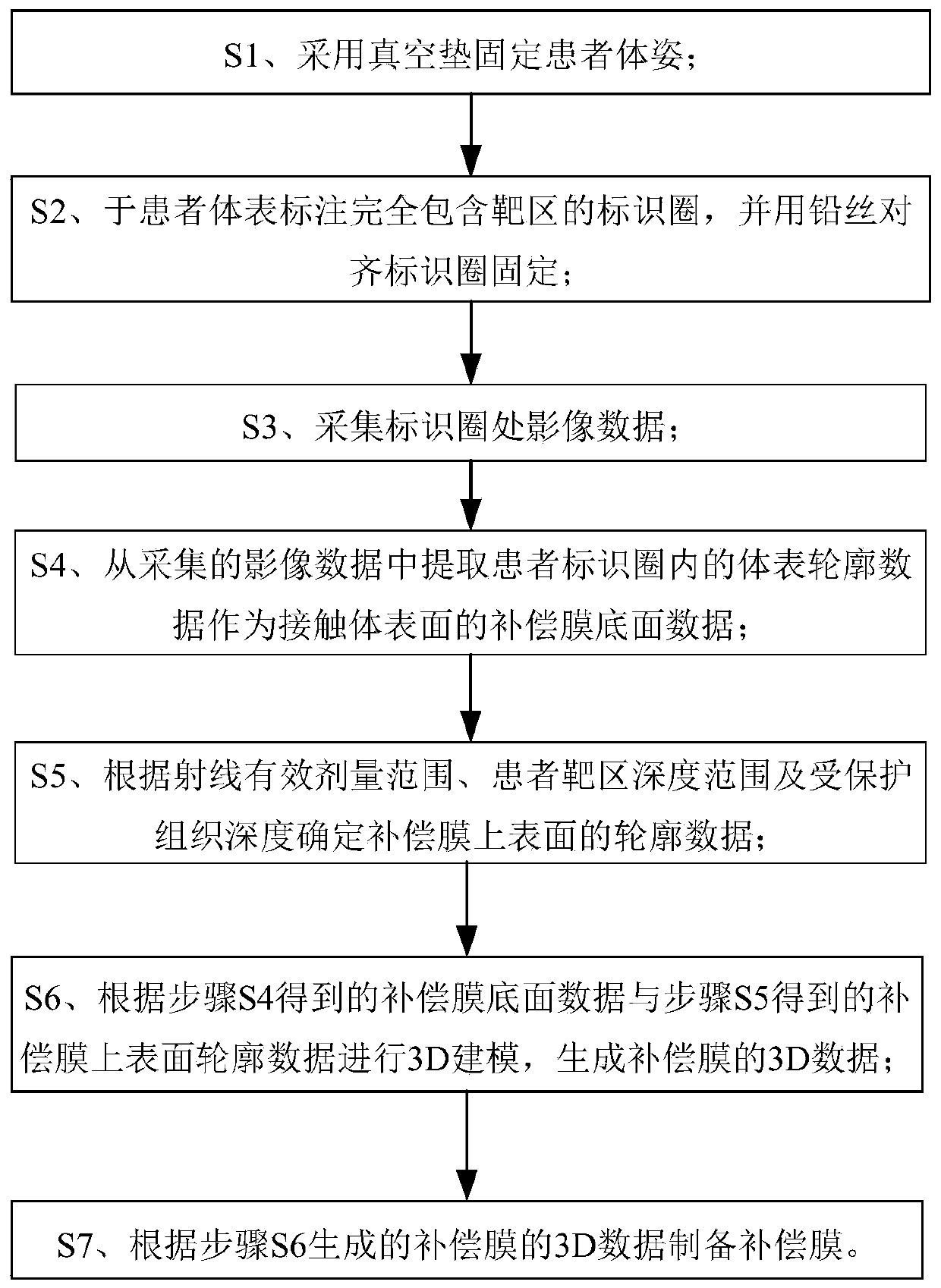

[0027] Such as figure 1 Shown is the method flowchart of the present invention, a kind of individualized compensation membrane preparation method of the present invention, comprises:

[0028] Step 1: The patient lies on the vacuum cushion, adopts a posture that is least affected by respiratory movement at the radiotherapy site, and is easy to repeat, vacuumizes the patient's phantom and fixes it;

[0029] Step 2: On the CT bed, the patient lies on the vacuum phantom, repeats the posture of the model, and draws a marking circle on the patient's body surface with a marker pen that is no thicker than 1 mm in thickness, and uses a lead wire of the same thickness as the line Put the lead wire on the marking line and fix it, scan CT, and reconstruct t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com