Preparation technology and production system of imitation natural texture landscape brick

A preparation process and a natural imitation technology, applied in the field of preparation technology and production system of imitation natural textured landscape tiles, can solve the problems of simple effect, inability to achieve the effect of natural granite texture, roughness and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

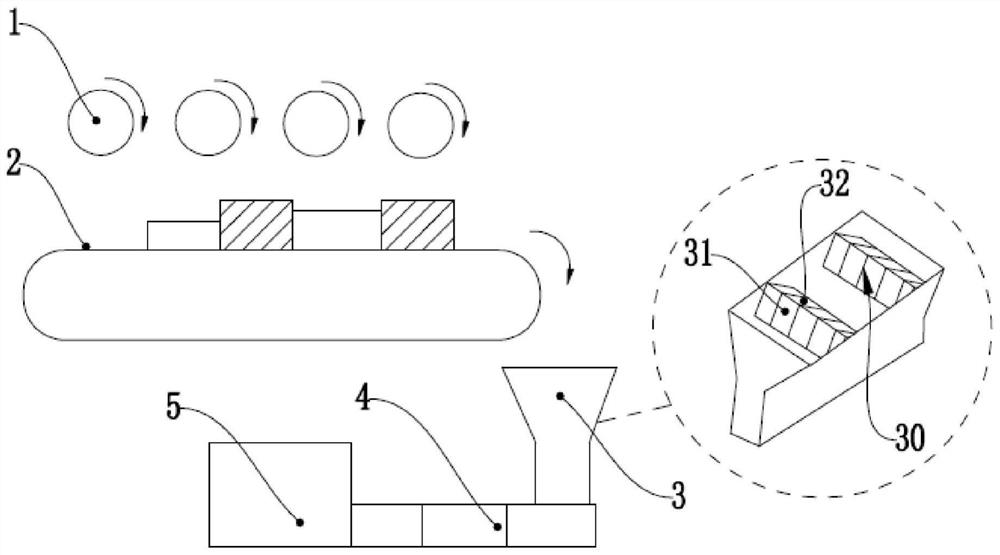

[0029] A preparation process for imitating natural texture landscape bricks, comprising the following steps:

[0030] Step A, preparation of speckle powder: using ceramic base material raw materials to prepare white base material and black base material respectively by wet spray powdering method, mixing white base material and black base material to obtain the speckle powder;

[0031] Step B, preparation of pattern powder: using the white primer in step A as the basic primer, then adding dry-mixed coloring material, and dry mixing to prepare at least one pattern powder;

[0032] Step C: Add the powders obtained in Steps A and B into their respective feeding devices, and feed each powder to the surface of the same conveying main belt according to the amount set for different powders. The feeding sequence and discharge speed of the feeding device, as well as the conveying speed of the main conveying belt, make each powder material be fed to different areas of the main conveying ...

Embodiment 1

[0071] A preparation process for imitating natural texture landscape full-body bricks is characterized in that it comprises the following steps:

[0072] Step A, preparation of speckled powder: use conventional ceramic primer raw materials to prepare white primer and black primer respectively by wet spray powdering method, take the white primer and the black primer according to the weight percentage of raw materials For 90:10 mixing, add the mixed raw materials into the atomizer, and dry them into granules by contacting with the hot air flow to obtain light white speckled powder;

[0073] Step B, preparation of pattern powder: use the white base material in the step A as the base base material, add 1% yellow dry-mixed coloring material according to the weight percentage of the raw material, and use the method of dry powder making to mix the raw material Mix through homogenizing equipment and enter weighing equipment, then granulate through a granulator, and finally dry in a fl...

Embodiment 2

[0079] A preparation process for imitating natural texture landscape full-body bricks is characterized in that it comprises the following steps:

[0080] Step A, preparation of speckled powder: use conventional ceramic base material raw materials to prepare white base material and black base material respectively by wet spray powdering method, take the white base material and the black base material according to the weight percentage of raw materials For 80:20 mixing, add the mixed raw materials into the atomizer, and dry them into granules through contact with hot air to obtain light white speckled powder;

[0081] Step B, preparation of pattern powder: use the white base material in the step A as the base base material, add 0.8% yellow dry-mixed coloring material according to the weight percentage of the raw material, and use the method of dry powder making to mix the raw material Mixing through homogenizing equipment and entering weighing equipment, then granulating through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com