A yoga mat rolling film packaging equipment

A technology for packaging equipment and yoga mats, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of packaging quality dependent on proficiency, unfavorable yoga mat odor, and high training costs for workers, so as to achieve good promotion and application value and structure Simplicity and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

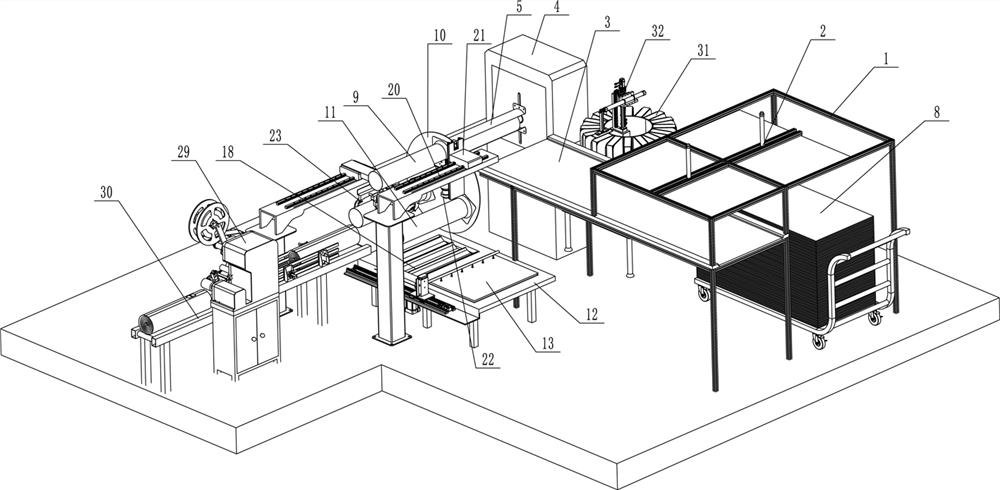

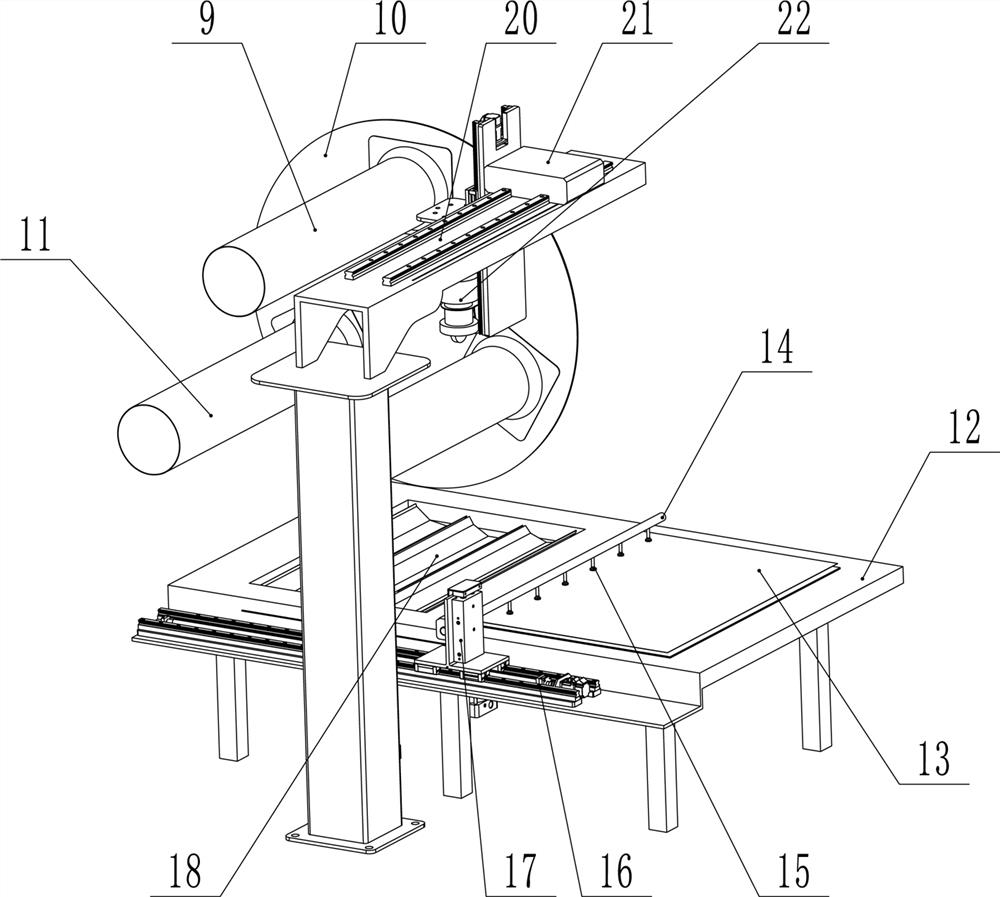

[0033] Such as Figure 1-Figure 7 As shown, a yoga mat rolling film packaging equipment includes the following components:

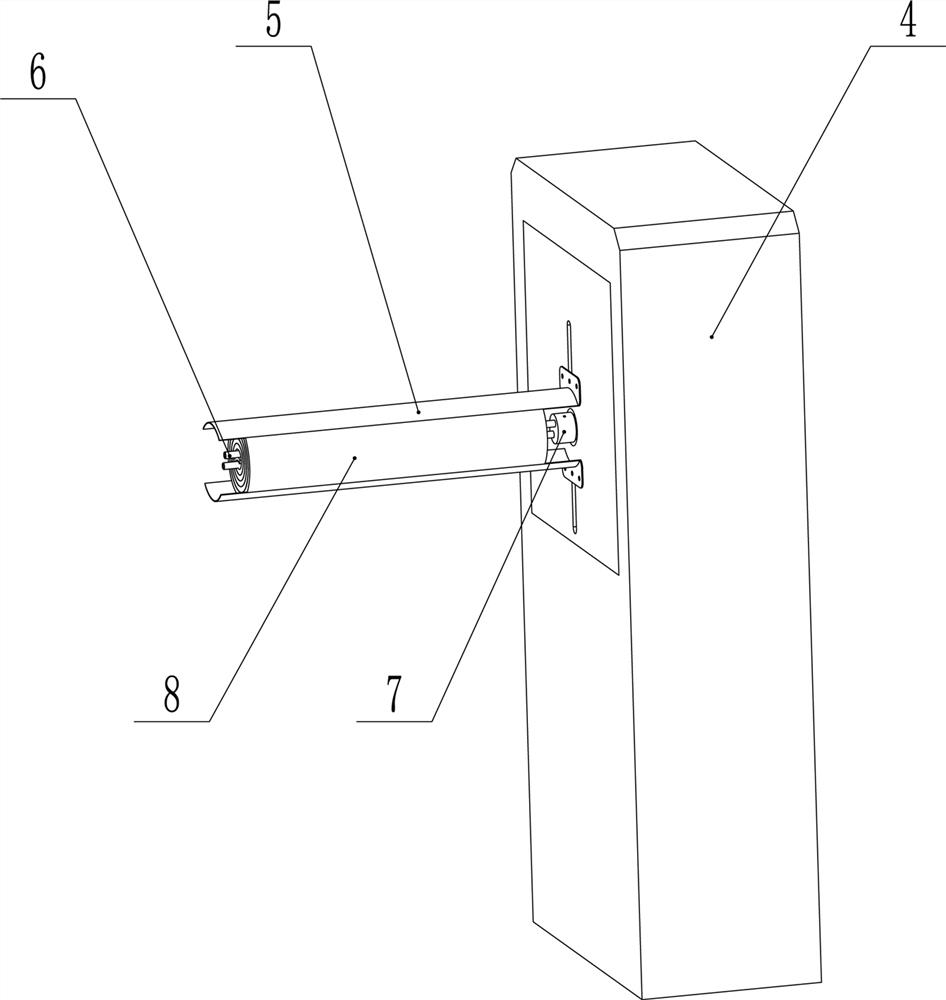

[0034] Loading machine, the loading machine is a truss 1 and a suction cup mechanical claw 2, and the yoga mats are stacked and flattened in the storage area, and the flattened yoga mats are placed on the feeding conveyor belt 3 through the structure of the suction cup manipulator 2.

[0035] The accessory feeding mechanism is arranged on one side of the feeding conveyor belt 3 and is used for placing the accessories on the yoga mat. It includes a plurality of positions 31 arranged in a circle, a suction cup manipulator 32 arranged at the center of the plurality of positions 31, and a rotating platform 33 that drives several positions to rotate. The suction cup manipulator does not rotate with the rotating platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com