Method for efficiently separating active polysaccharides from fresh okra

A technology of active polysaccharides and okra, applied in the field of efficient separation of active polysaccharides, three-phase system combined with ammonium sulfate precipitation, to achieve good anti-oxidation and hypoglycemic activities in vitro, low cost, and large economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1, fresh okra homogenization treatment: 500 g of commercially available fresh okra was cleaned, sliced, added 1500 g of distilled water for homogenization treatment, and filtered through gauze to obtain filtrate and filter residue;

[0023] Step 2, three-phase system separation: add 1000mL of okra filtrate obtained in step 1 to 200g of ammonium sulfate, stir to dissolve, adjust the pH value of the solution to 7.0, add 1500mL of tert-butanol, shake in a constant temperature water bath at 35°C for 30min, 4500rpm Centrifuge for 10 min, and take out the upper layer tert-butanol phase and the lower layer ammonium sulfate phase respectively;

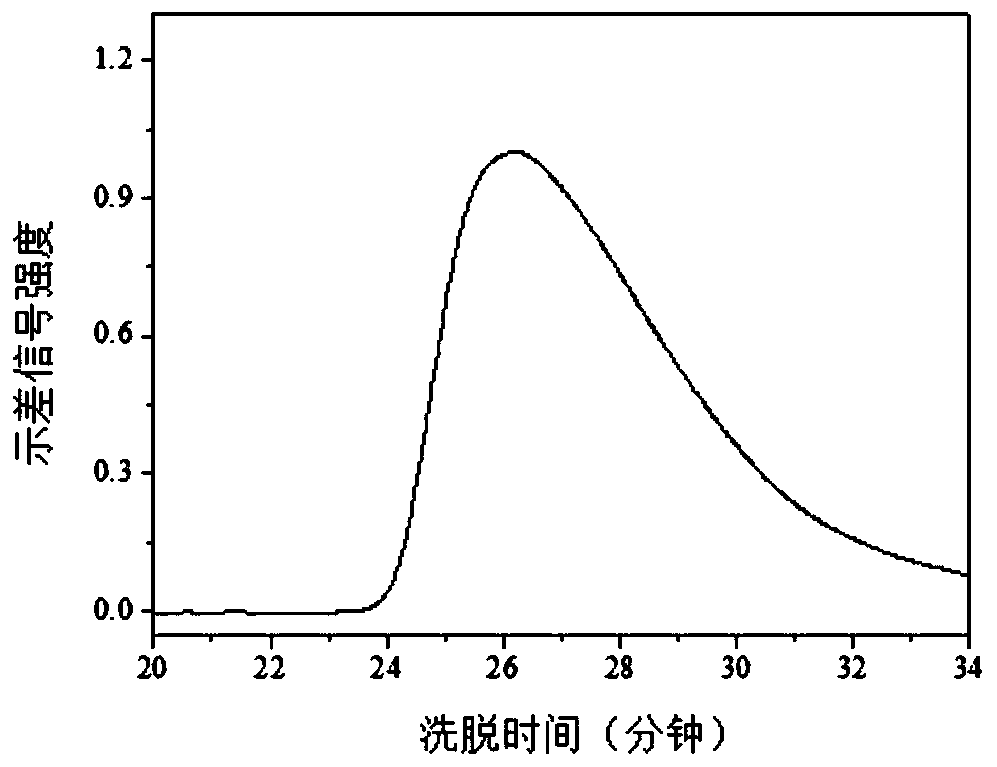

[0024] Step 3, ammonium sulfate precipitation and separation of okra polysaccharides: add 100 g of ammonium sulfate to the 1000 mL of ammonium sulfate phase solution obtained in step 2, so that the mass fraction of ammonium sulfate in the solution is 30%, centrifuge, dissolve the precipitate in water, and dialyze for 48 hours. Conc...

Embodiment 2

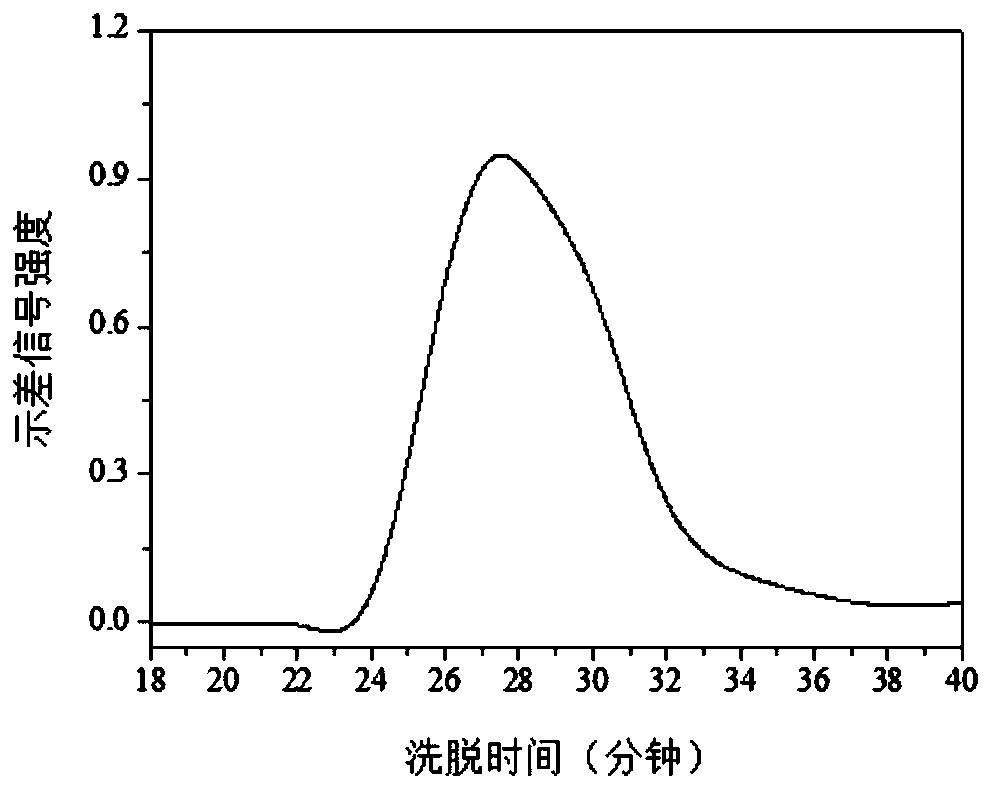

[0027] The test process is the same as in Example 1, except that 300 g of ammonium sulfate is added in step 3 so that the mass fraction of ammonium sulfate in the solution is 50%. The total sugar content of okra polysaccharides measured is 93.5%, and the molecular weight distribution is a single peak, such as figure 2 Shown, the weight average molecular weight is 3.6×10 6 Da, IC for scavenging DPPH radicals 50 The value is 0.045mg / mL, the equivalent antioxidant capacity is 71.3μmol Trolox / g sample, and the ability to reduce ferrous ions is 169.3μmol FeSO 4 / g sample, IC of α-amylase inhibitory activity 50 The value is 0.10 mg / mL.

Embodiment 3

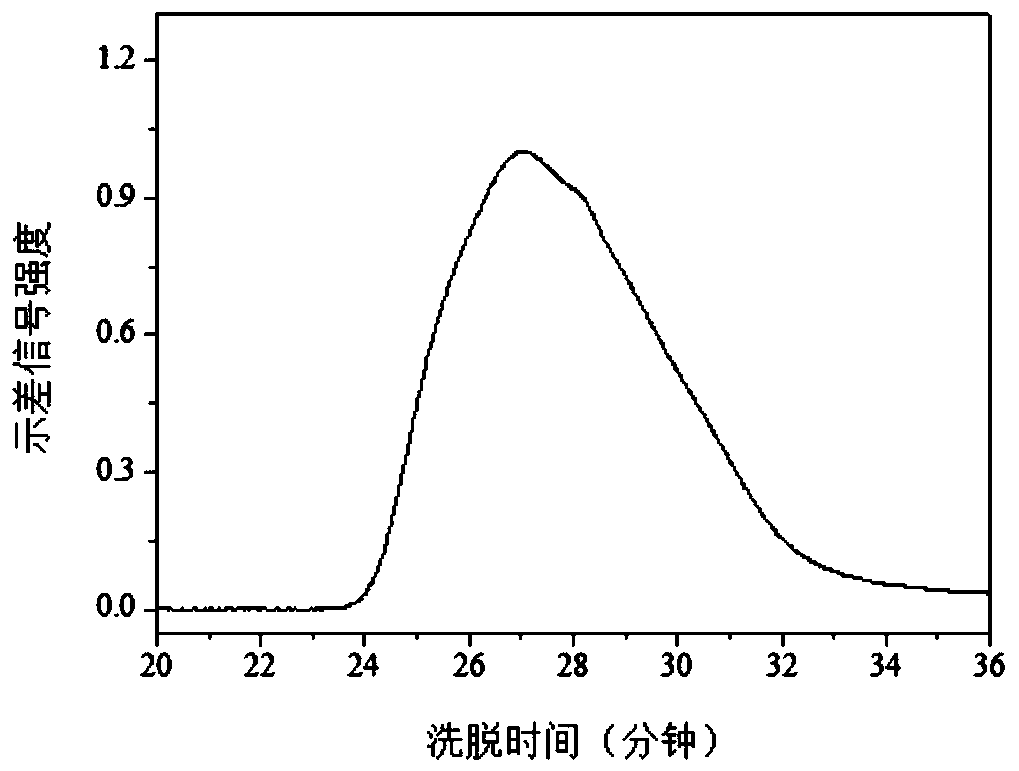

[0029] The test process is the same as in Example 1, except that 200 g of ammonium sulfate is added in step 3 so that the mass fraction of ammonium sulfate in the solution is 40%. The total sugar content of okra polysaccharides measured is 90.1%, and the molecular weight distribution is a single peak, such as image 3 Shown, the weight average molecular weight is 4.3×10 6 Da, IC for scavenging DPPH radicals 50 The value is 0.11mg / mL, the equivalent antioxidant capacity is 68.2μmol Trolox / g sample, and the ability to reduce ferrous ions is 161.8μmol FeSO 4 / g sample, IC of α-amylase inhibitory activity 50 The value is 0.15 mg / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com