Ring box supporting enclosure system capable of doubling as retaining wall and construction method for ring box supporting enclosure system

A technology of retaining walls and ring frames, which is applied in excavation, artificial islands, water conservancy projects, etc., can solve the problems of large impact on construction plots and surrounding plots, large excavation volumes, long construction periods, etc., to achieve project reliability High implementability, high engineering applicability, and the effect of reducing the thickness of the covering soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

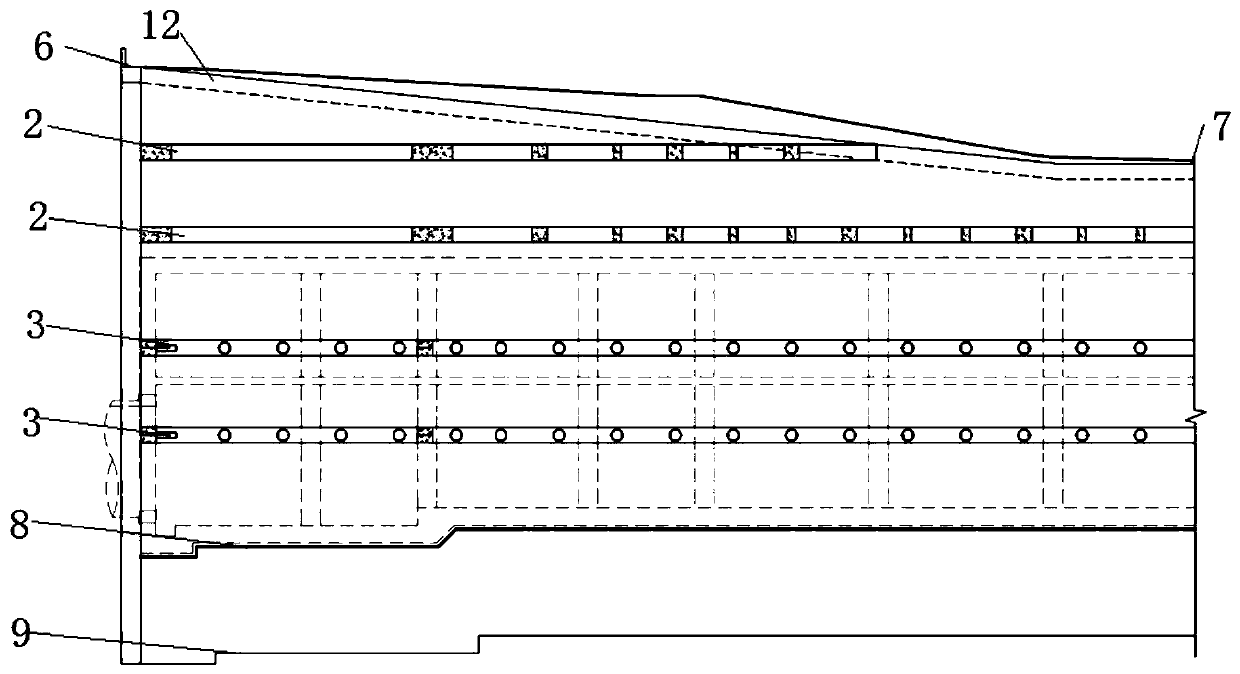

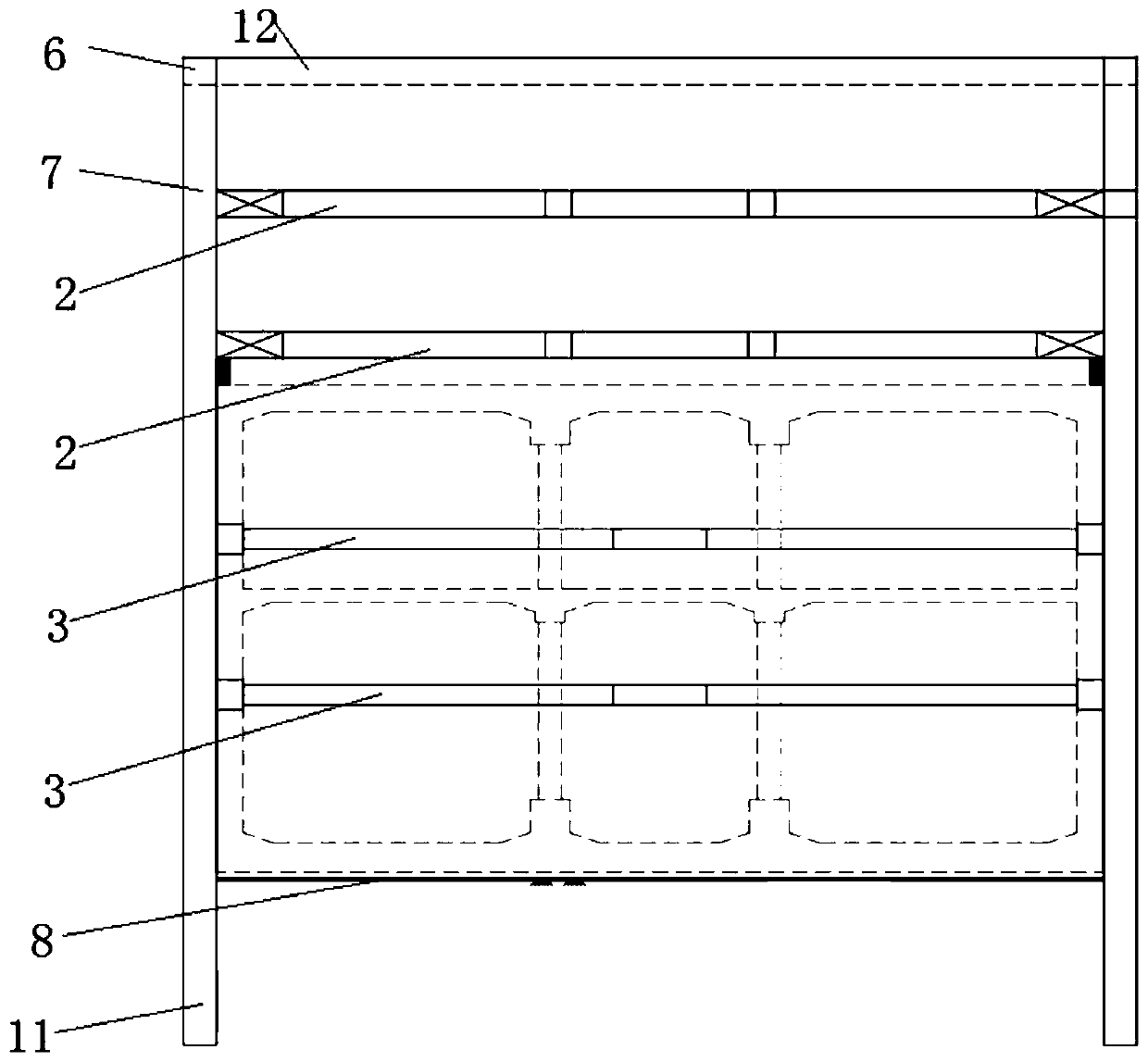

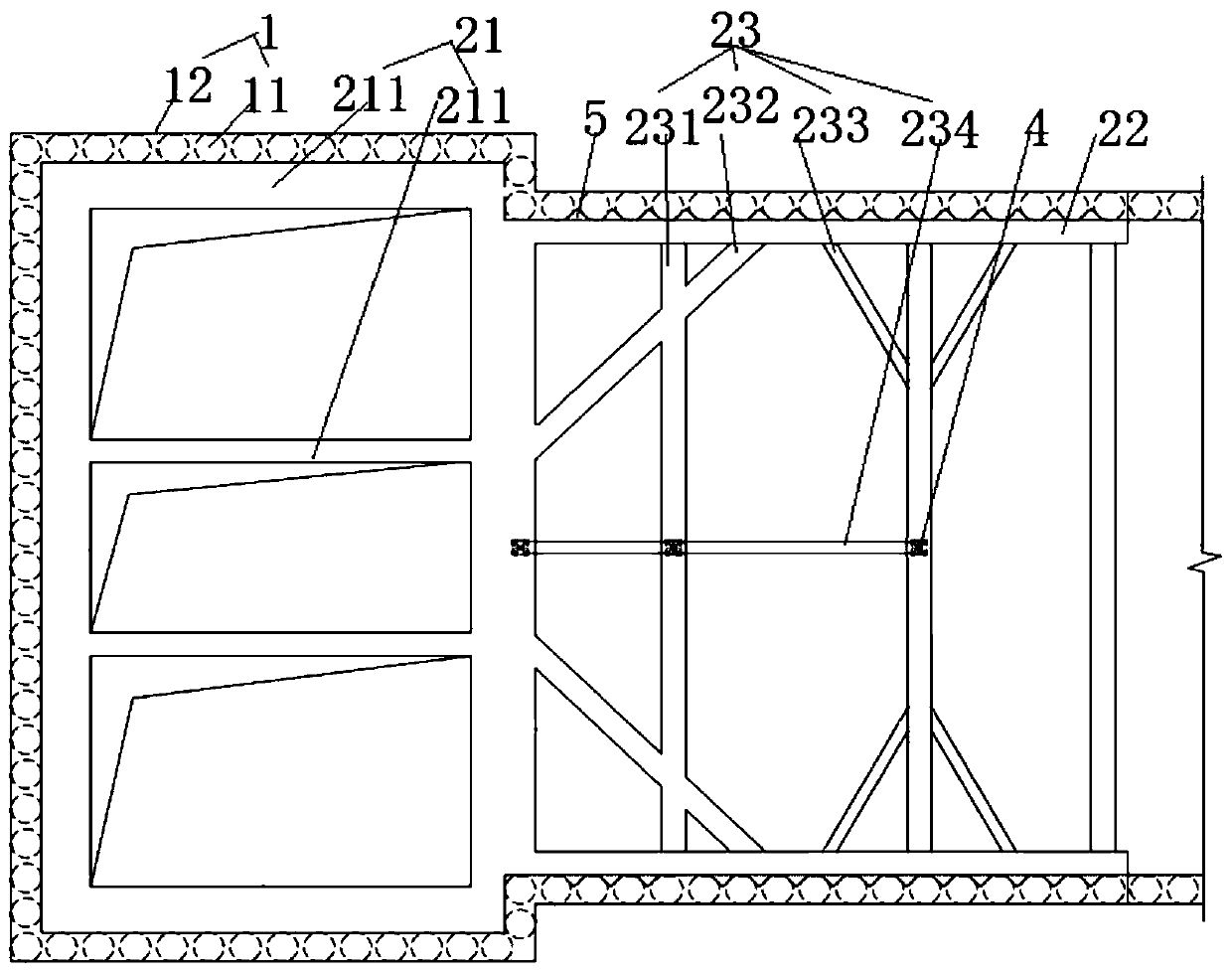

[0042] This embodiment discloses a ring frame support enclosure system that can double as a retaining wall, such as Figure 1-5 As shown, it includes a retaining structure 1 surrounding the foundation pit for bearing the lateral load of the foundation pit, and a concrete support structure 2 surrounding the retaining structure 1 for balancing the lateral load on the retaining structure 1;

[0043] The concrete support structure 2 includes ring frame beams 21 respectively arranged on both sides of the retaining structure 1, and concrete waist beams 22 for connecting the ring frame beams 21, and the concrete waist beams 22 are arranged close to the soil retaining structure 1; the concrete support structure 2 is provided with a support member 23.

[0044]In this embodiment, a sectioned steel center column 4 is installed between the concrete support structures 2; the arrangement of the section steel center column 4 can reduce the span for large-span support.

[0045] In this embod...

Embodiment 2

[0061] This embodiment discloses a ring frame support enclosure system that can also be used as a retaining wall. The retaining structure 1 and the concrete support structure 2 are the same as the embodiment 1. The difference between the construction method and the embodiment 1 is:

[0062] The distance between the ground and the top floor of the field is not more than 5m, and in step S2, there is no need to add the first concrete support structure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com