Far infrared coal scuttle heater

A far-infrared and heater technology, applied in the direction of heating elements, ohmic resistance heating parts, etc., can solve the problems of uneven heating, long time-consuming, inconvenient operation, etc., to improve production efficiency, avoid clogging of the bucket opening, and operate convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

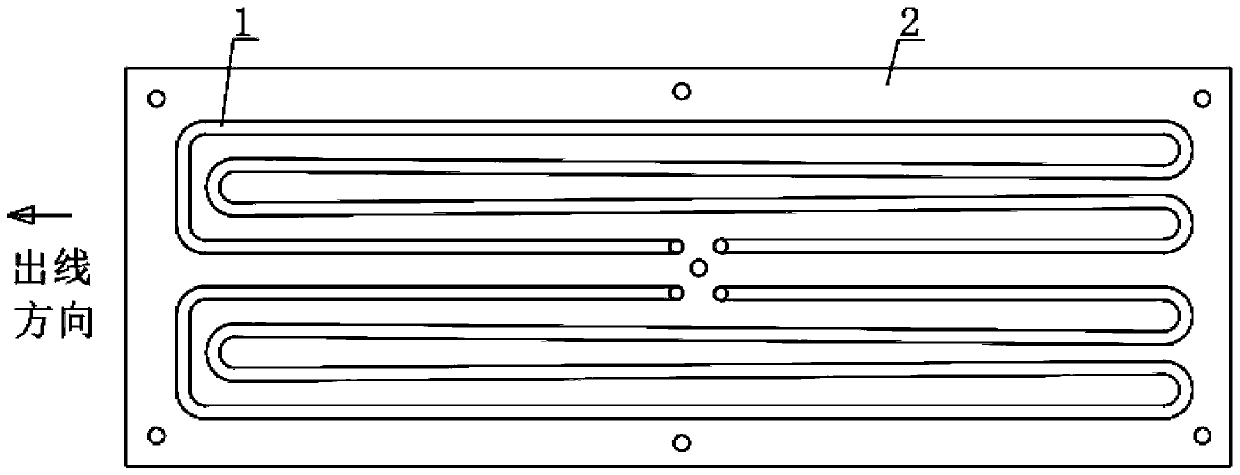

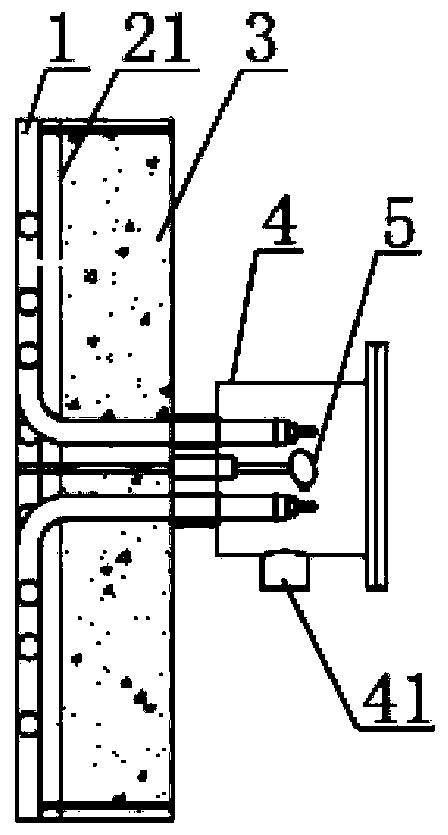

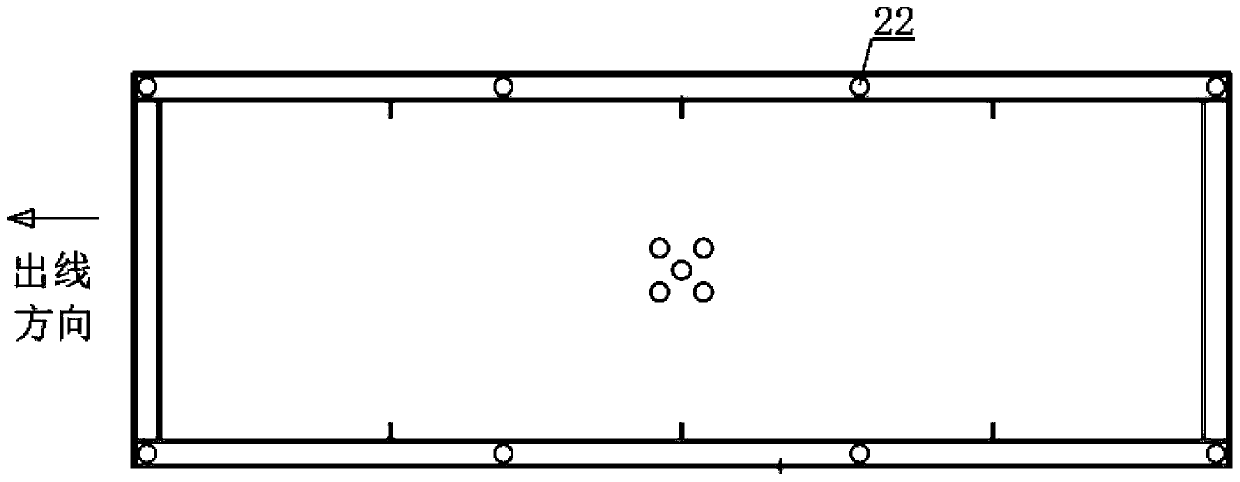

[0022] As shown in the figure, a far-infrared coal hopper heater is fixedly installed on the bottom coal outlet 100 of the coal hopper 300 according to the structural characteristics of the coal hopper 300. Pre-heat the coal outlet at the bottom of the coal hopper to defreeze, avoid clogging of the hopper mouth, ensure smooth coal flow in the coal hopper, and help improve productivity; in order to improve the heating effect and thawing efficiency, this embodiment is arranged side by side on the outer wall of the coal hopper coal outlet Three far-infrared coal scuttle heaters 200, a longitudinal partition 101 is respectively arranged between adjacent far-infrared coal scuttle heaters 200, and the height of the longitudinal partition 101 is higher than the total thickness of the outer shell of the far-infrared coal scuttle heater 200, preventing mutual Interference, to ensure stable and reliable system operation.

[0023] The specific structure of the far-infrared coal hopper he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com