Thermoforming die in-mold punching equipment with heating devices

A heating device and thermoforming technology, applied in the field of die punching, can solve problems such as easy breakage, and achieve the effect of reducing contact temperature and improving practical life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

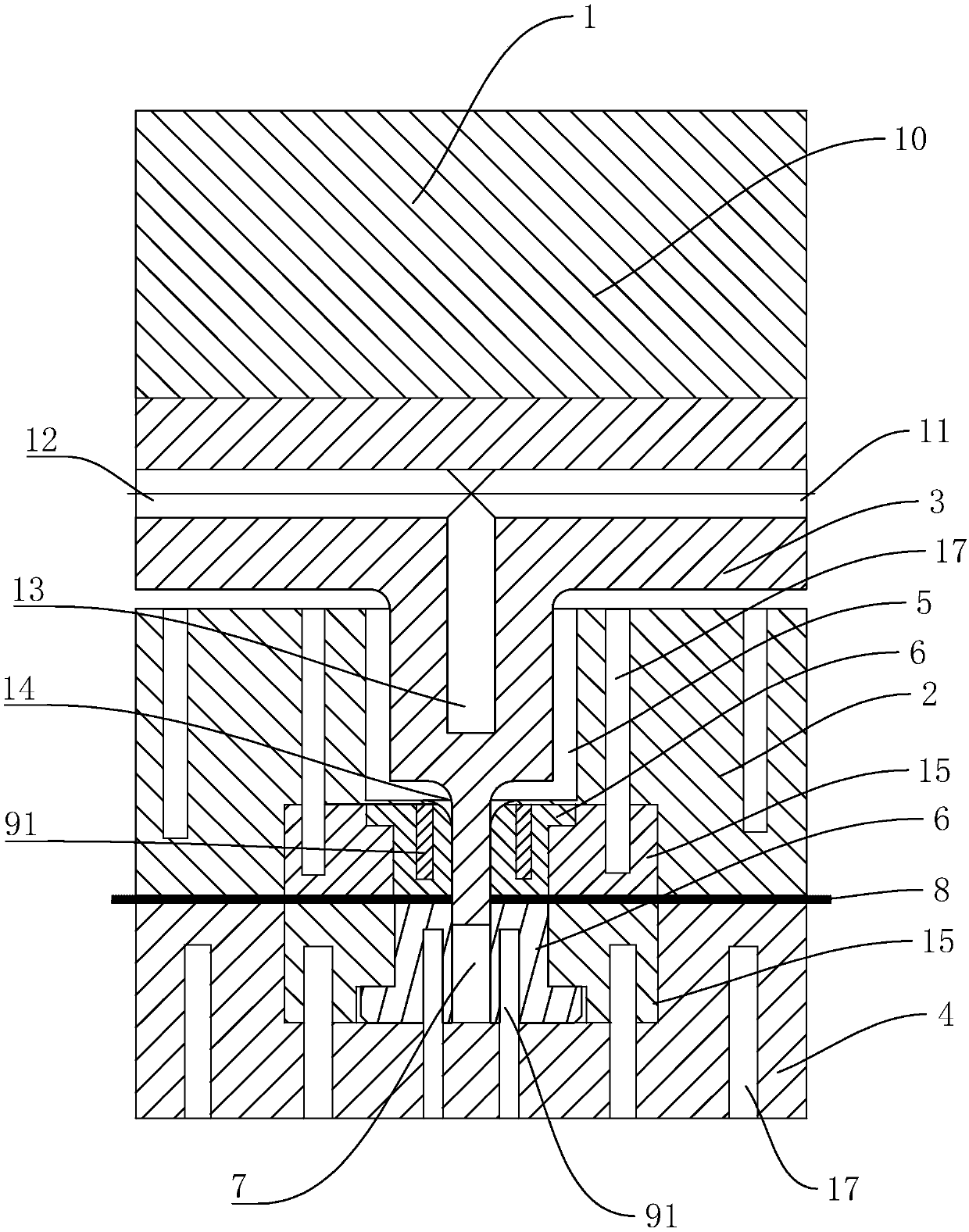

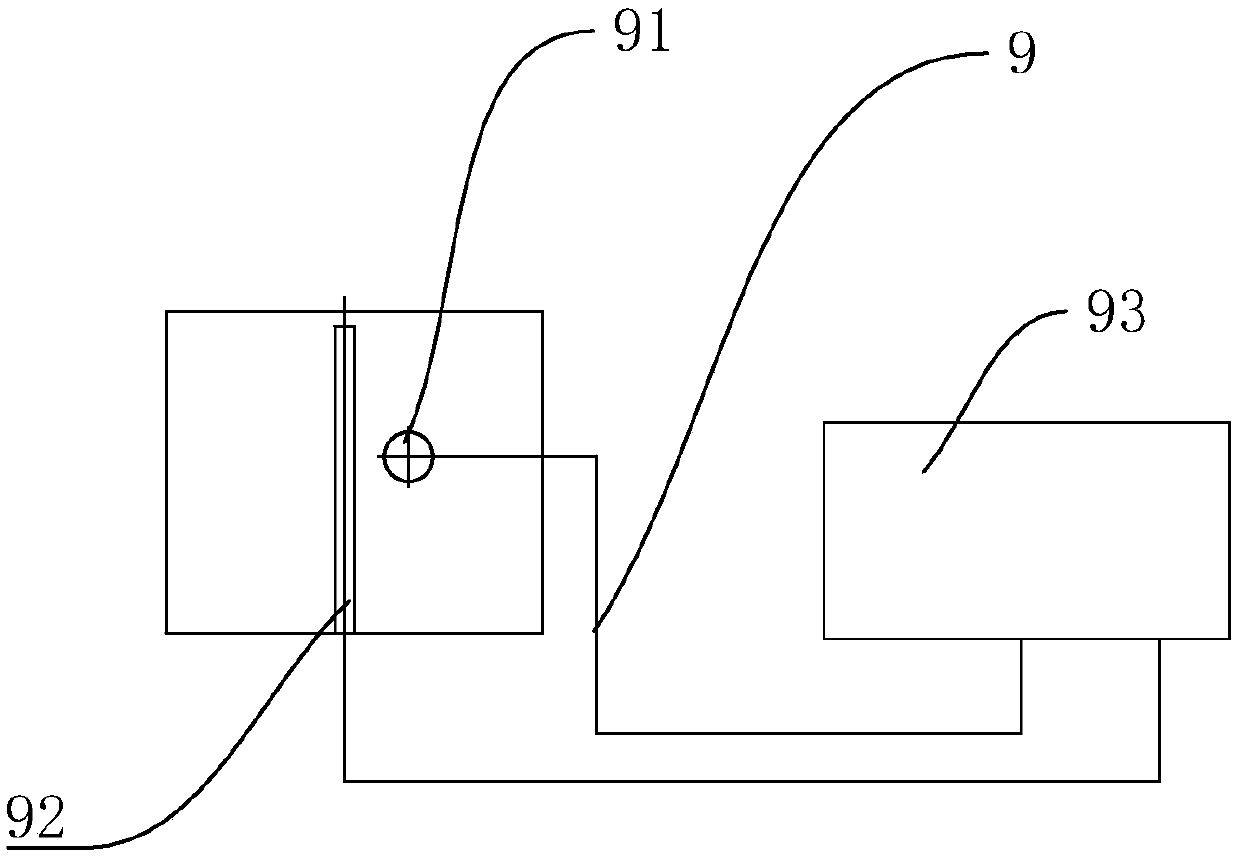

[0032] Embodiment 1: a kind of in-die punching of thermoforming die with heating device, such as figure 1 As shown, it includes a mounting base 1, a pressing plate 2, a punch 3 and a support base 4, the punch 3 is fixed on the mounting base 1, and the pressing plate 2 has a stepped hole on the side facing the mounting base 1 5. The punch 3 is set towards the stepped hole 5, and the punch 3 extends out of the stepped hole 5 under pressure; the support seat 4 and the place on the binder plate corresponding to the punch 3 are provided with a die bushing 6, The center of the die bushing 6 is provided with a punching hole 7, the die bushing 6 is flush with the surface of the support seat 4, the workpiece 8 is placed between the binder plate 2 and the support seat 4, the die The bushing 6 and the support seat 4 are also provided with a heating device 9, the heating device 9 includes a heating rod 91, a temperature sensor 92 and a heating control system 93, the heating rod 91 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com