Method and equipment for improving selectivity of light olefins

A low-carbon olefin and selectivity technology, applied in the field of olefin preparation, can solve the problem of low selectivity of low-carbon olefins, achieve the effect of improving the selectivity of low-carbon olefins, saving floor space and investment, and reducing the temperature of reaction oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

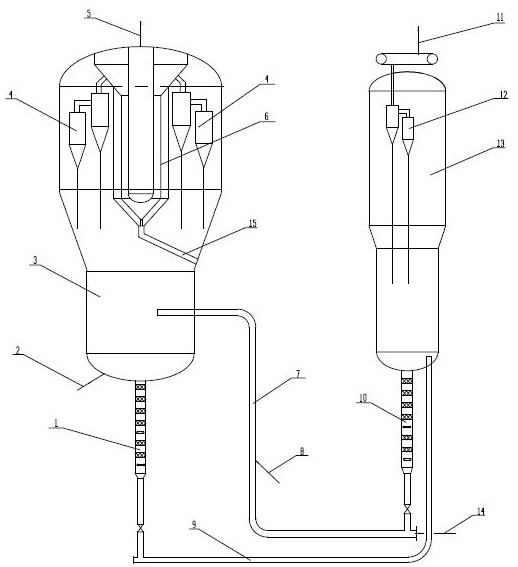

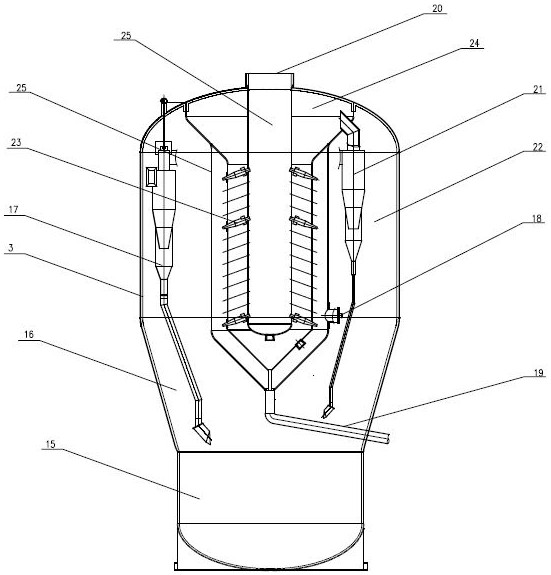

[0050] like figure 1 As shown, the raw material oxygen-containing compound 2 (mainly including methanol, dimethyl ether, C4-C10 alcohol compounds or their mixtures) enters the reactor 3 after preheating, and the oxygen-containing compound 2 in the reactor 3 is mixed with the pre-reaction section. The high-temperature regenerated catalyst of 7 directly contacts, and the exothermic reaction is carried out rapidly on the surface of the catalyst. After the catalyst, it is drawn out from the top of the reactor 3 and sent to the rear quench water washing system after heat exchange. The catalyst recovered by the built-in separation facility 6 is discharged to the outside of the reactor 3 through the waste catalyst conveying pipe 19 . After the reaction, the coke-deposited catalyst enters the stripper 1 to be stripped to remove the oil and gas entrained in the catalyst. After coking in the regenerator 13, the regenerated catalyst enters the regeneration stripper 10 for stripping and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com