Heat dissipation device and heat dissipation method for aluminum substrate gong plate

A heat dissipation method and technology of aluminum substrate, applied in the direction of maintenance and safety accessories, milling machine equipment, electrical components, etc., can solve problems such as scrapping, clogging of gongs and knives, excessive burrs of aluminum substrate, etc., to ensure chip removal ability, low cost, Improve the effect of scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention provides a heat dissipation device and heat dissipation method for an aluminum substrate gong plate. In order to make the purpose, technical solution and effect of the present invention more clear and definite, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

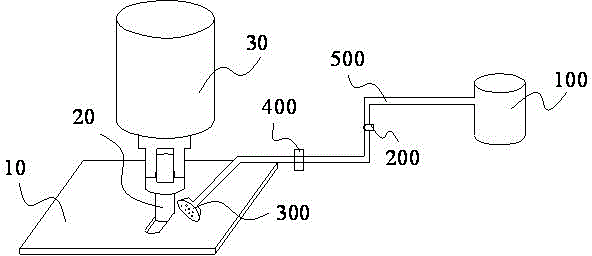

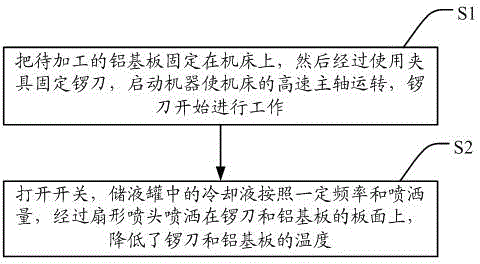

[0022] see figure 1 , which is a schematic diagram of an embodiment of the heat dissipation device for the aluminum substrate gong board of the present invention. As shown in the figure, the heat dissipation device includes: a liquid storage tank 100 for storing cooling liquid, an automatic motor 200, a fan nozzle 300, a switch 400 and a conduit 500; The spray head 300 , the switch 400 and the automatic motor 200 are arranged on the conduit 500 .

[0023] read on figure 1 , when starting to work, the aluminum substrate 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com