Pump unit for providing a hydraulic pressure for actuating an actuator in the drive train of a motor vehicle

A hydraulic pressure and pump unit technology, applied in the direction of engine components, engine working fluid, pump components, etc., can solve problems such as damage and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

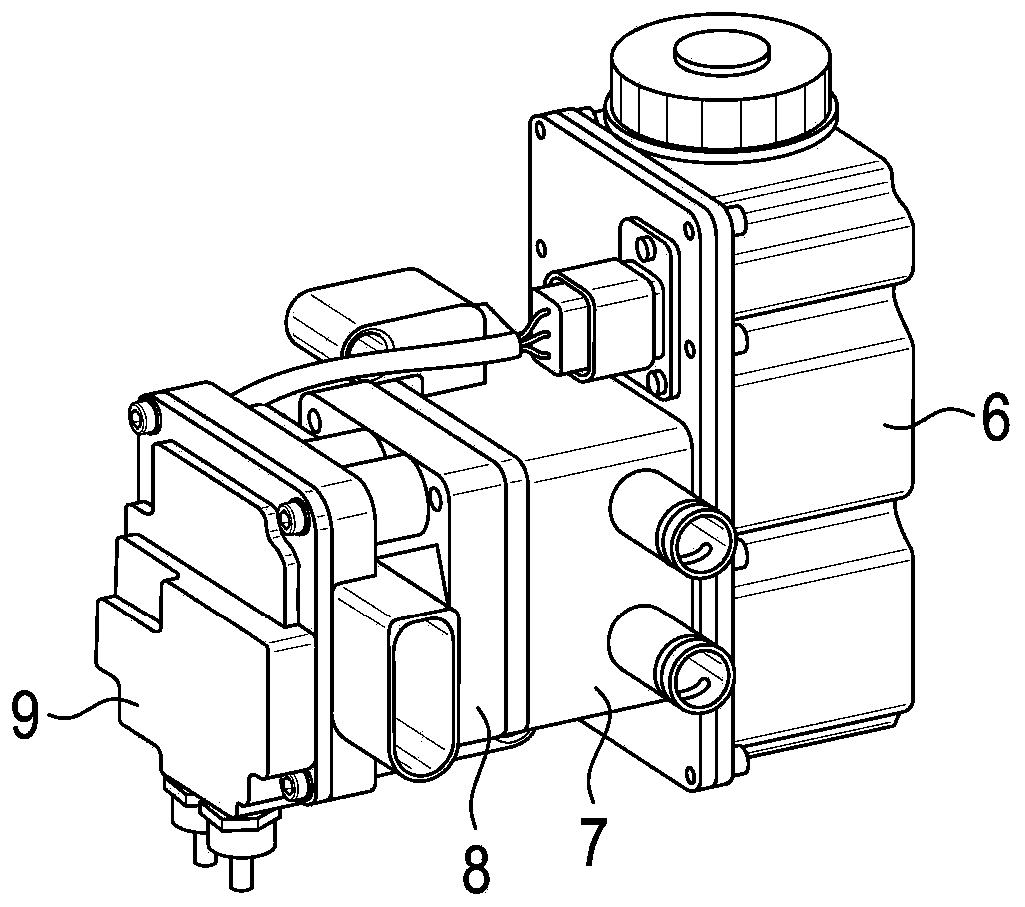

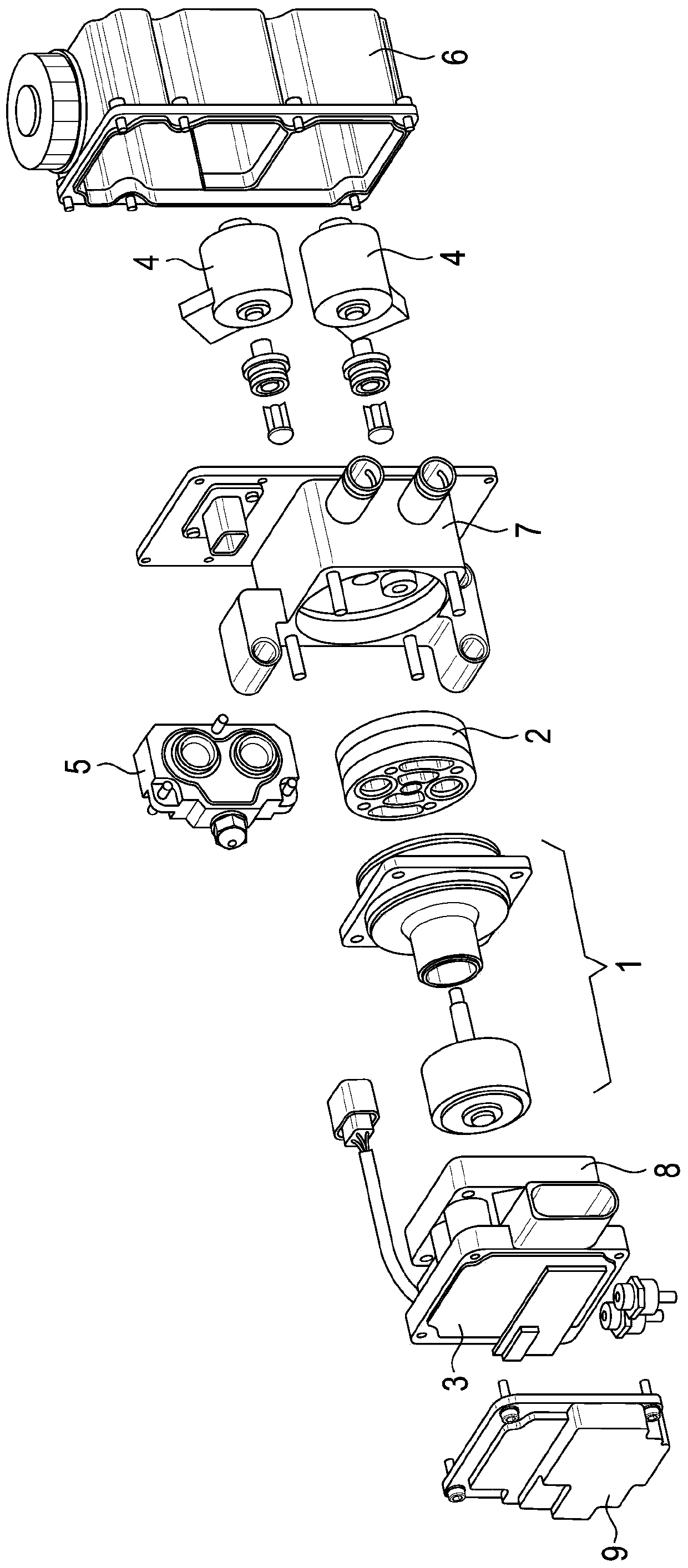

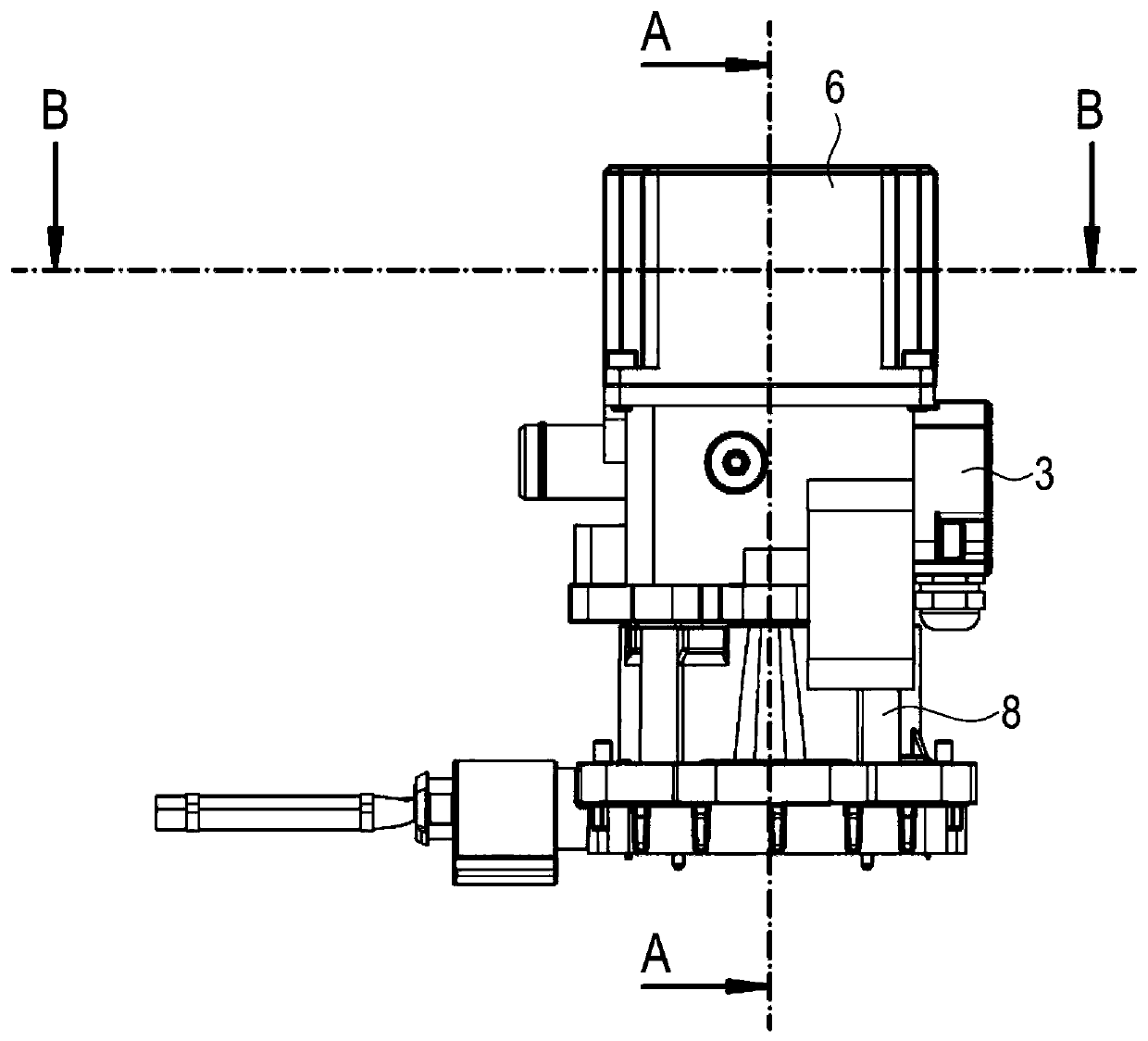

[0037] The figures show a pump unit for providing hydraulic pressure (and hydraulic fluid flow) which can be converted into actuation strokes by actuators in the drive train of a motor vehicle. For example, the actuation stroke can be used to close or open a clutch, or it can be used to switch gear stages of a transmission or bring it into a neutral position.

[0038] As a basic component (see for details figure 1 with 2 ), the pump unit has a drive motor 1 , a pump 2 , an electronic control system 3 , two solenoid valves 4 , two pressure sensors 5 , and has a storage container 6 accommodated in a common housing.

[0039] The central part of the pump unit is the pump housing 7 on which the solenoid valve 4 is mounted and on which the storage container 6 is also mounted. A pressure sensor 5 is also mounted on the pump housing 7 .

[0040] On the side opposite the storage container 6 , an electronics housing 8 is mounted on the pump housing 7 , said electronics housing housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com