Stirring device capable of realizing full mixing and used for production of low-temperature waterborne transparent paint

A technology of fully mixing and stirring devices, applied to mixers with rotating stirring devices, mixers, mixer accessories, etc., can solve problems such as damage, temperature differences in liquid areas, and affecting solute dissolution efficiency, and achieve good temperature control effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

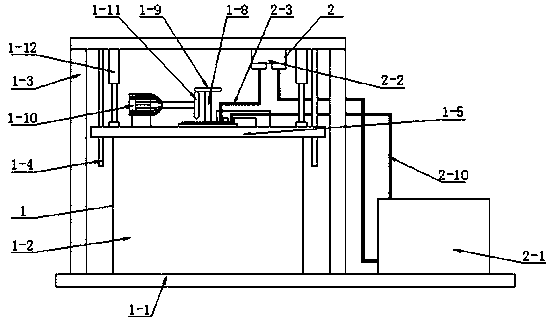

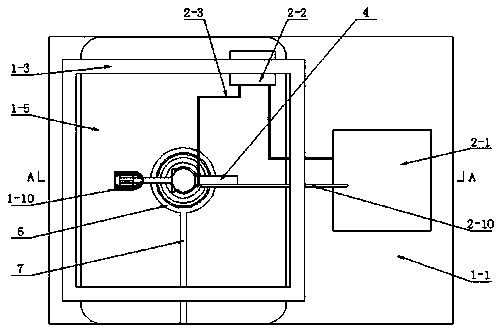

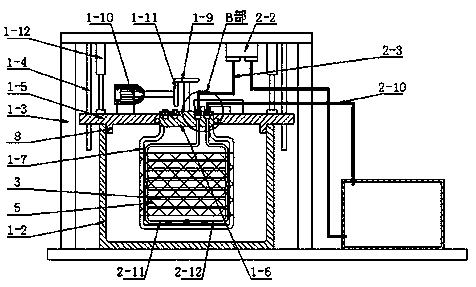

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] see as Figure 1-Figure 4 As shown, this specific embodiment includes a stirring component 1 and a temperature control component 2, wherein the stirring component 1 is fixed on the ground, the temperature control component 2 is erected on the stirring component 1, and the output end of the temperature control component 2 is movably inserted in the Inside the stirring assembly 1,

[0027] The mixing assembly 1 includes a base 1-1, a mixing cylinder 1-2, a bracket 1-3, a cover plate 1-5, a mounting seat 1-6, a stirring frame 1-7, a motor 1-10, and a hydraulic stroke 1- 12. The base 1-1 is poured and fixed on the ground, the base 1-1 is riveted with a mixing tank 1-2, the base 1-1 is welded with a bracket 1-3, and the bracket 1-3 is erected on the mixing tank 1- 2, the lower surface of the upper side wall of the bracket 1-3 is welded with a guide rod 1-4, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com