Gravel cyclic crushing and screening mechanism

A technology of cyclic crushing and crushing mechanism, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of troublesome operation and large volume of stones, and achieve the effect of improving crushing efficiency and improving crushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

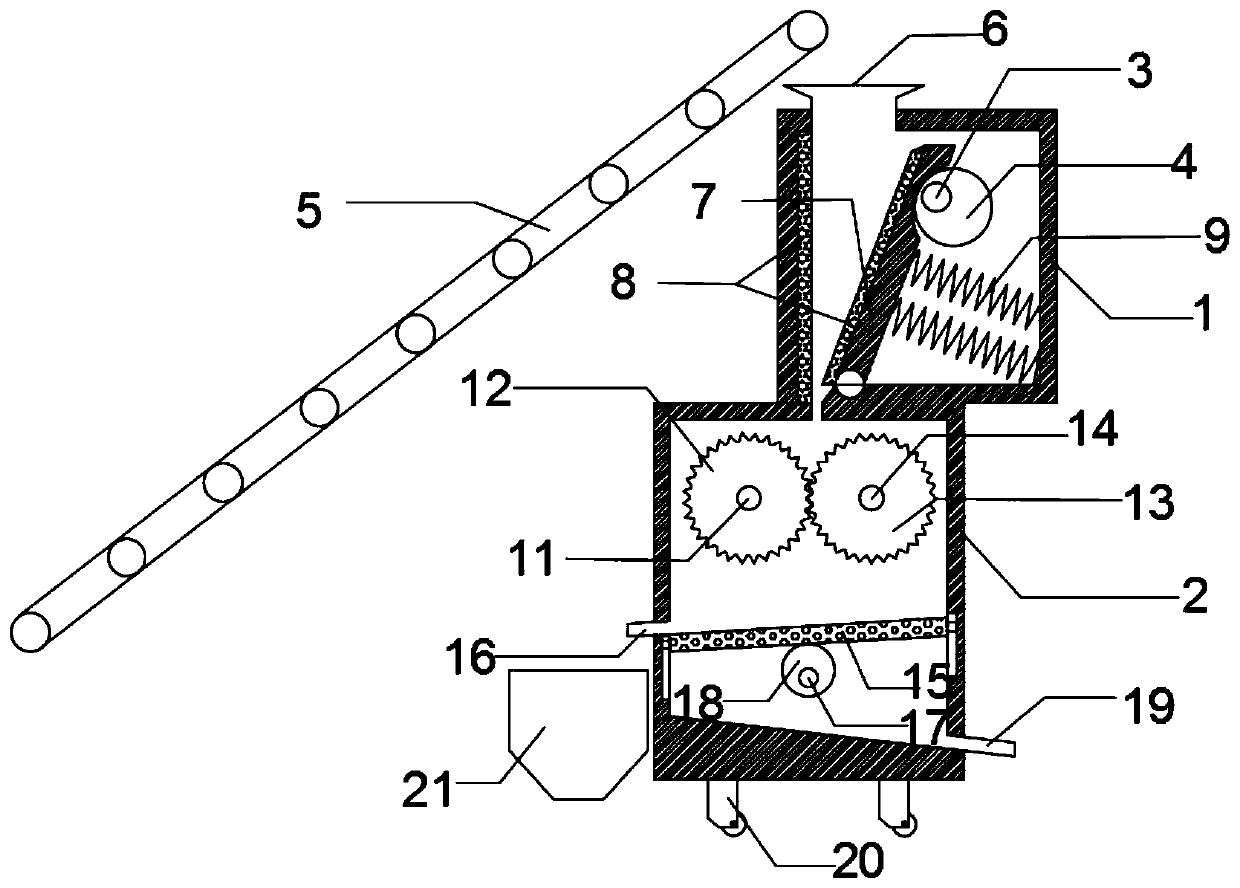

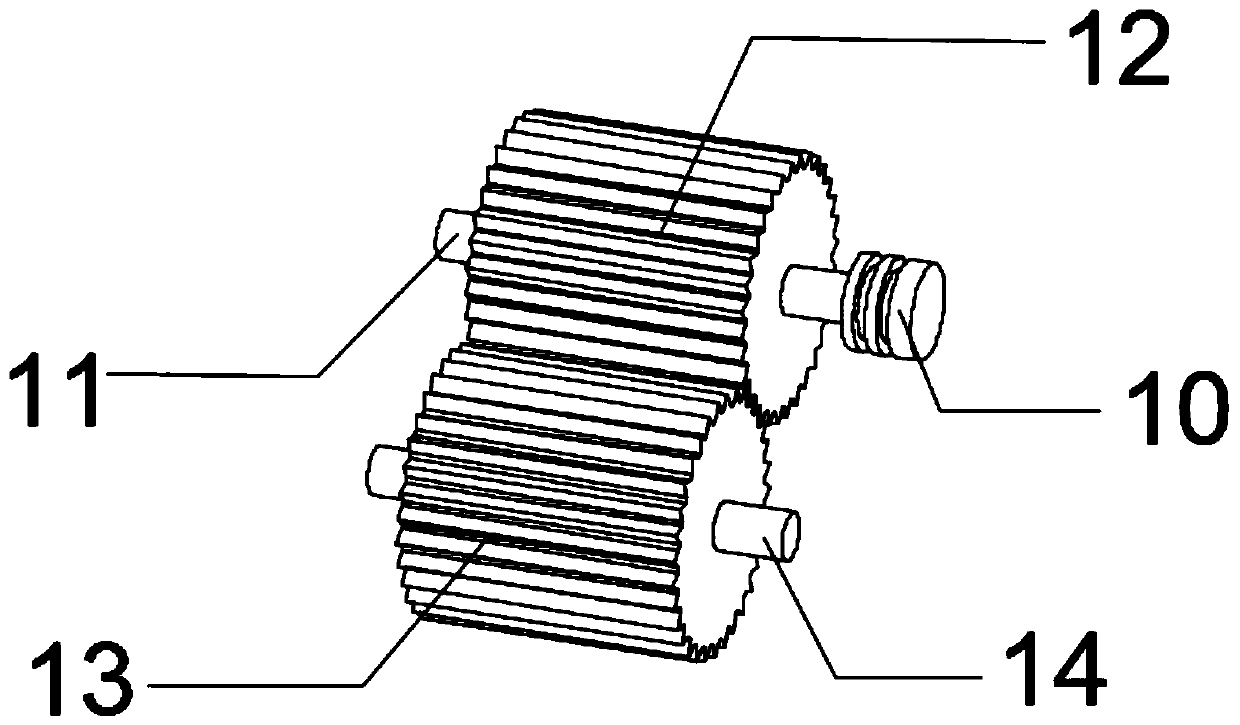

[0020] see Figure 1-2 , the present embodiment provides a gravel circulation crushing and screening mechanism, including a first crushing device housing 1, a second crushing device housing 2, a first crushing mechanism, a second crushing mechanism and a driving mechanism; the first crushing device The top of the shell 1 is provided with a feed inlet 6 for feeding, and a first crushing mechanism is arranged inside it;

[0021] The first crushing mechanism includes a first rotating shaft 3, a first eccentric wheel 4, a rotating plate 7 and a spring 9; the rotating plate 7 is fitted and slidably arranged on the inner wall of the first crushing device housing 1 and its bottom end is rotated At the bottom of the inner wall of the first crushing device housing 1; the upper right side of the rotating plate 7 is set as a semi-circular groove and the inside of the groove is fitted with a first eccentric wheel 4; the first eccentric wheel 4 is fixed to rotate It is arranged on the fir...

Embodiment 2

[0031] This embodiment is further improved on the basis of Embodiment 1, and the improvement is: a conveyor belt 5 for feeding is also provided on one side of the shell 1 of the first crushing device, and the primary stones collected by the collection box 21 After further pulverization through the conveyor belt 5, it can be pulverized completely.

[0032] The bottom of the housing 1 of the first crushing device is also provided with a plurality of wheels 20 for moving therewith.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com