Concrete block crushing device for building construction

A technology for concrete block and building construction, applied in the field of concrete, can solve the problems of increased dust concentration, endangering the health of external operators, difficulty in collection, etc., and achieves the effect of inhibiting a large amount of emission and protecting the health of the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

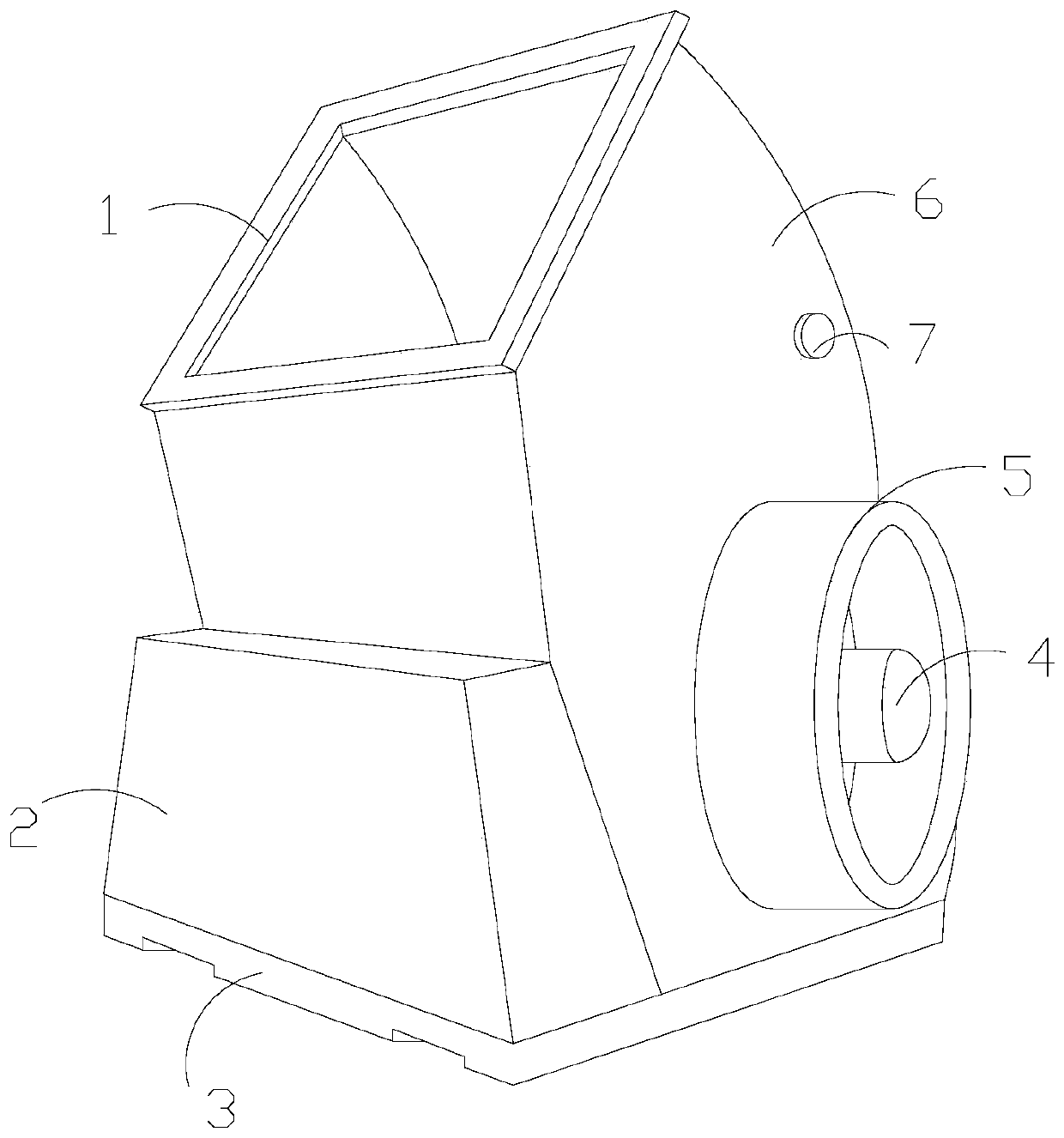

[0032] as attached figure 1 to attach Figure 10 Shown:

[0033] The invention provides a concrete block crushing device for building construction, the structure of which includes an outer frame 1, a front rail seat 2, a base plate 3, a crushing motor 4, a crushing wheel outer disk 5, a concrete block crushing cavity 6, and a concrete crushing and spacing device 7 The outer frame 1 is fixedly connected to the top of the concrete block crushing cavity 6 by means of electric welding, the crushing motor 4 is fixedly installed in the middle of the outer disk 5 of the crushing wheel, and the concrete crushing and spacing device 7 is installed in the Inside the concrete block crushing cavity 6, the top of the base plate 3 is fixedly connected to the bottom of the front rail seat 2 by means of electric welding.

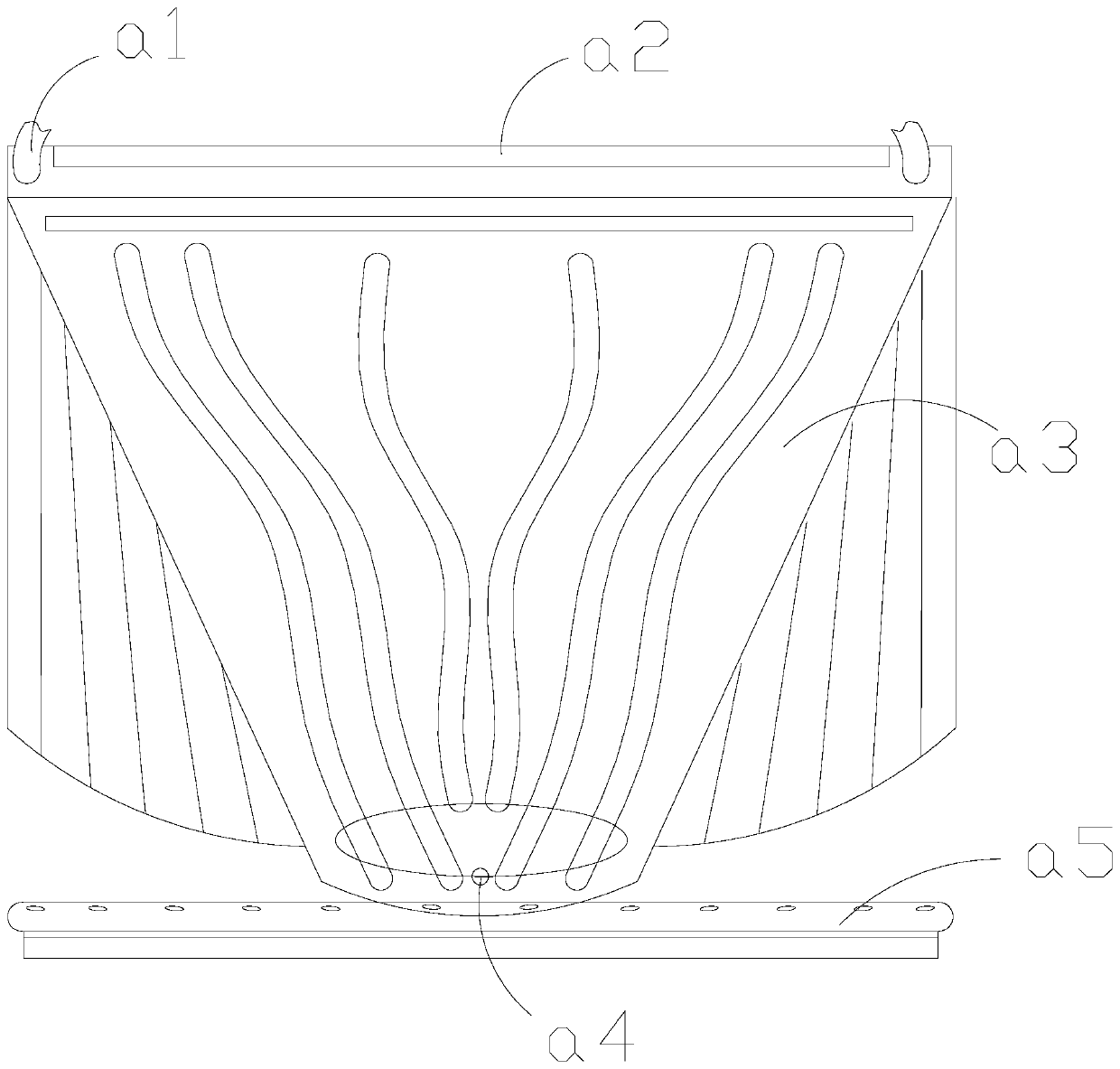

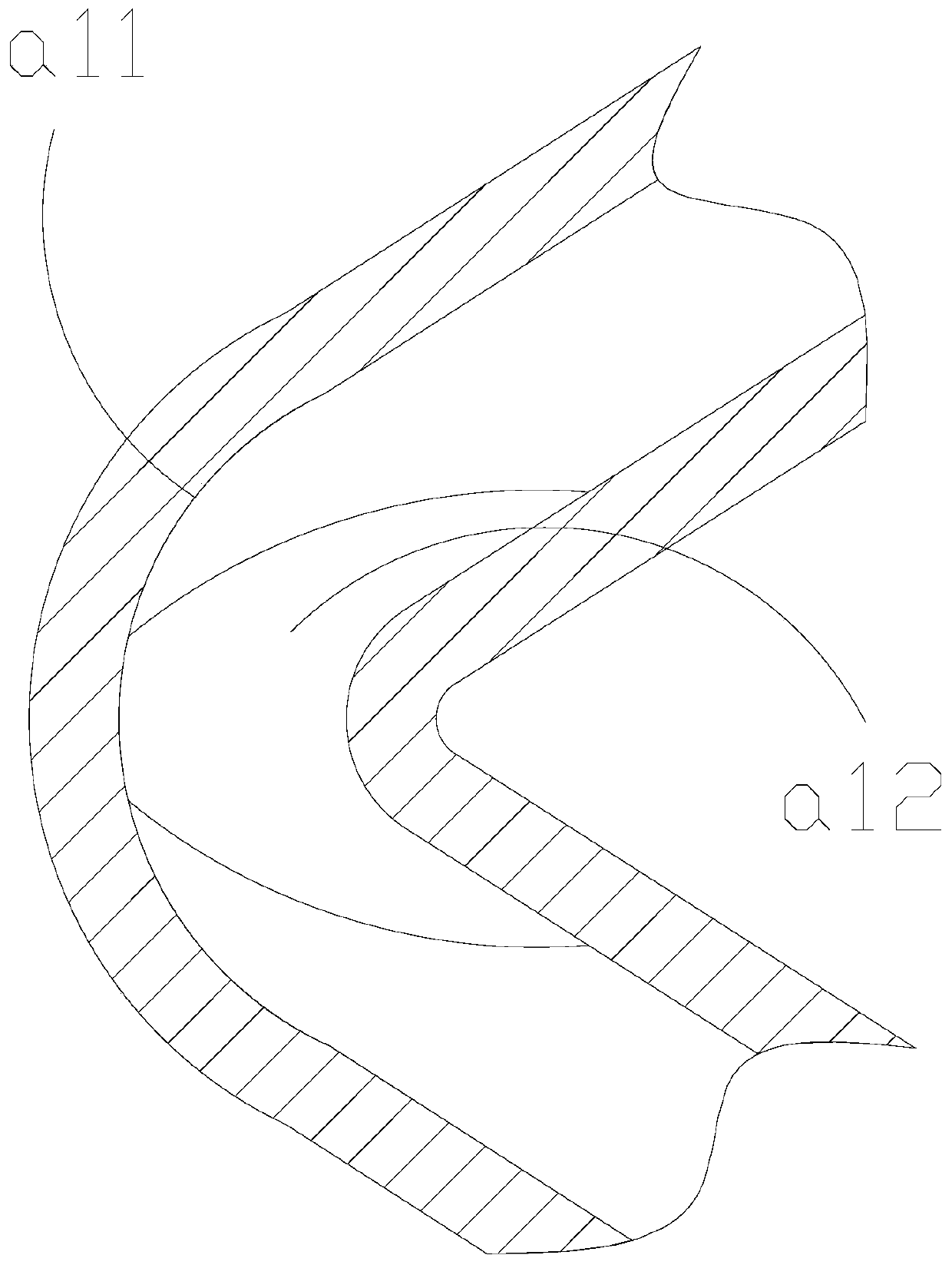

[0034] The concrete crushing and spacing adjustment device 7 includes an input mechanism a1, a rotating shaft a2, a spacing adjustment mechanism a3, a containment mechanis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap