Pipe cutting device capable of preventing cutting pieces from falling off and collecting automatically

A technology of automatic collection and pipe cutting device, applied in the direction of pipe shearing device, shearing device, accessories of shearing machine, etc., can solve the problems of inability to collect pipes, easy rolling and falling of pipes, etc., to increase the difficulty of collection, Avoid random scrolling and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

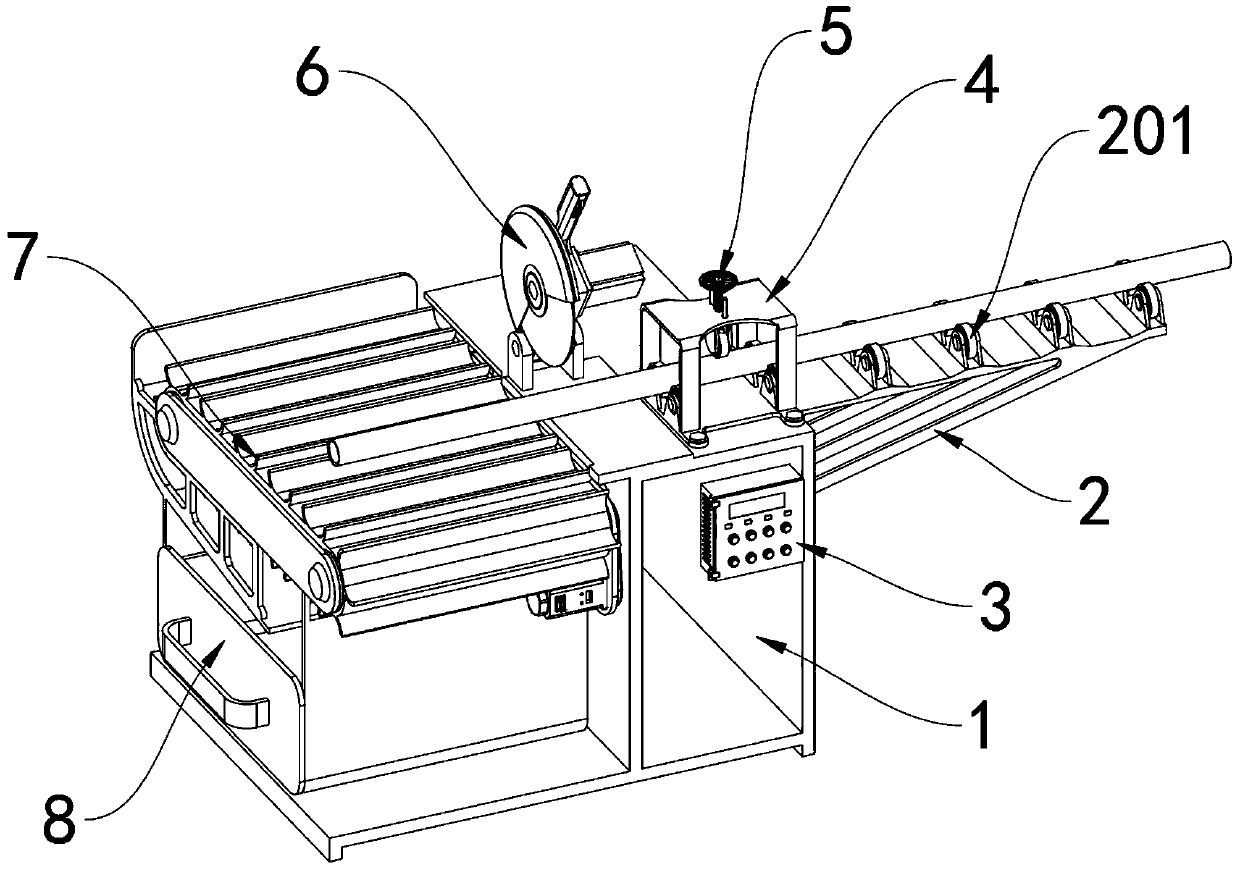

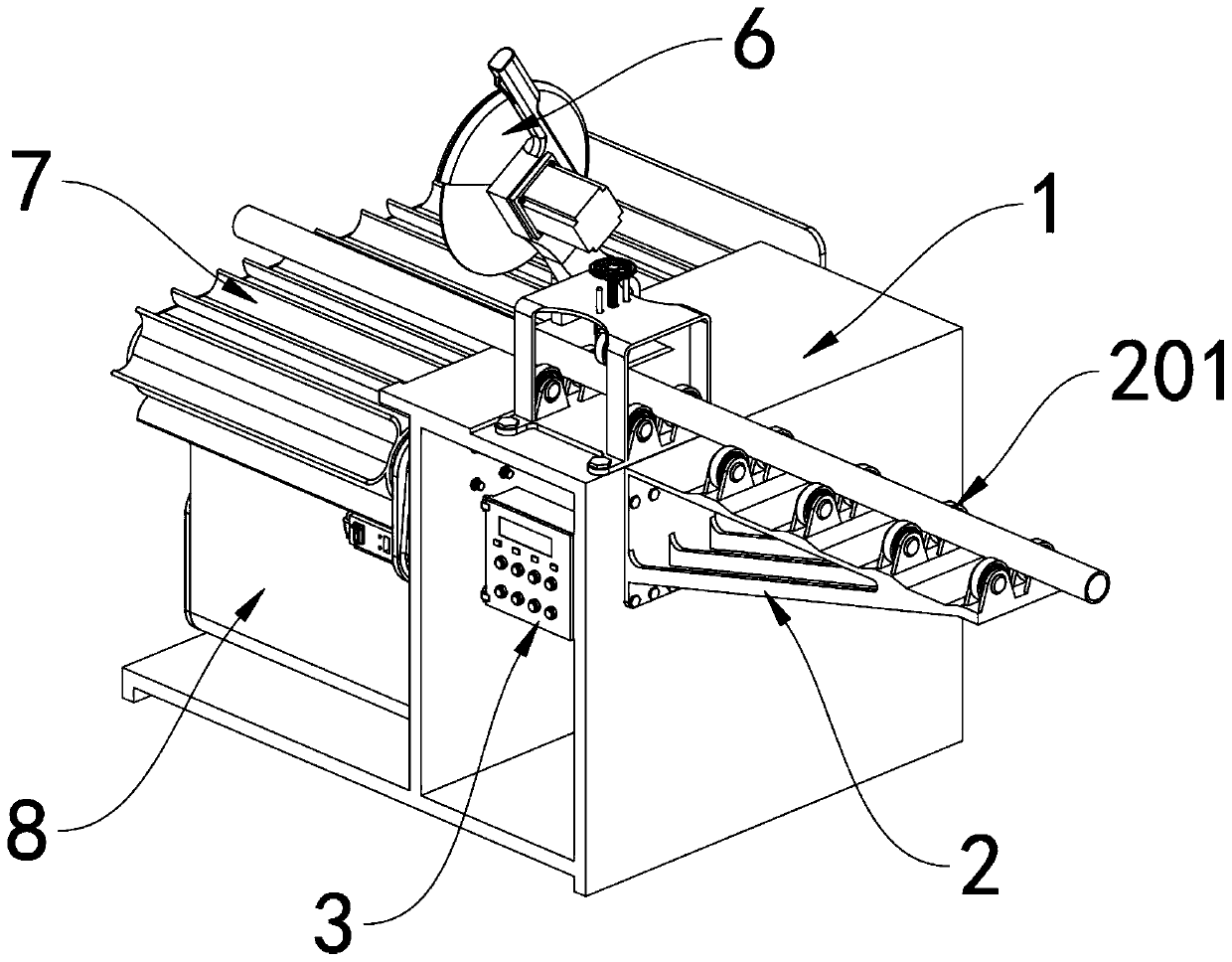

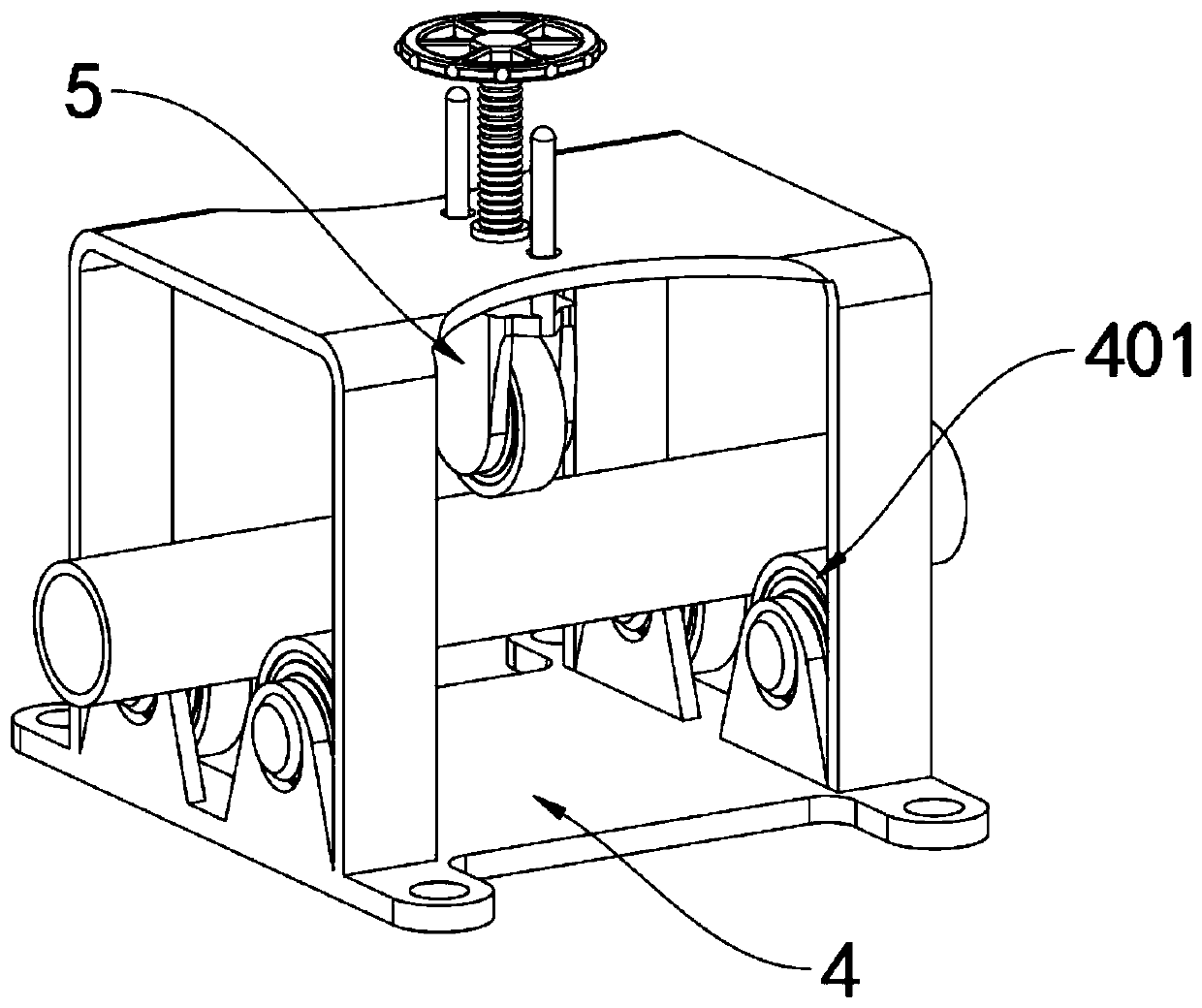

[0029] as attached figure 1 to attach Figure 9 Shown:

[0030] The present invention provides a pipe cutting device capable of preventing the cutting parts from falling and automatically collecting, including a main body seat 1, a limit fixing frame 4, an adjustment mechanism 5, a cutting machine 6, a conveying mechanism 7 and a storage mechanism 8; the right side of the main body seat 1 A pipe support frame 2 is installed on the top, and the control electric box 3 is installed inside the front end of the main body seat 1, and the control electric box 3 is connected to the external power supply line; the left side of the pipe support frame 2 is installed on the right end surface of the main body seat 1 by bolts , and the top of the pipe support frame 2 is provided with four sets of support rollers 201, the tail of the pipe can be auxiliary supported by the support rollers 201 on the top of the pipe support frame 2, so that the pipe remains horizontal and straight, and the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com