Centrifugal pump shell processing jig

A centrifugal pump and casing technology, applied in the field of centrifugal pump production, can solve the problems of centrifugal pump casing fixtures such as single function, insufficient practicability, and poor operation coordination effect, and achieve compact structure, convenient processing operation, and smooth operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

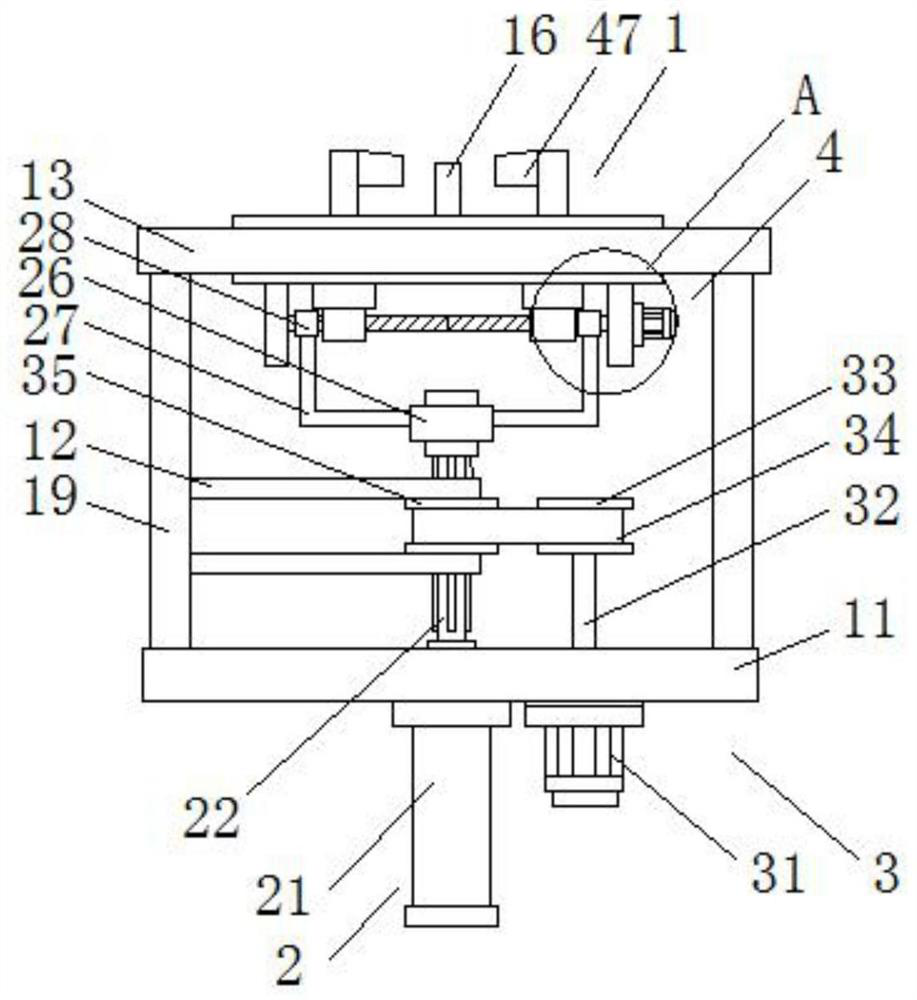

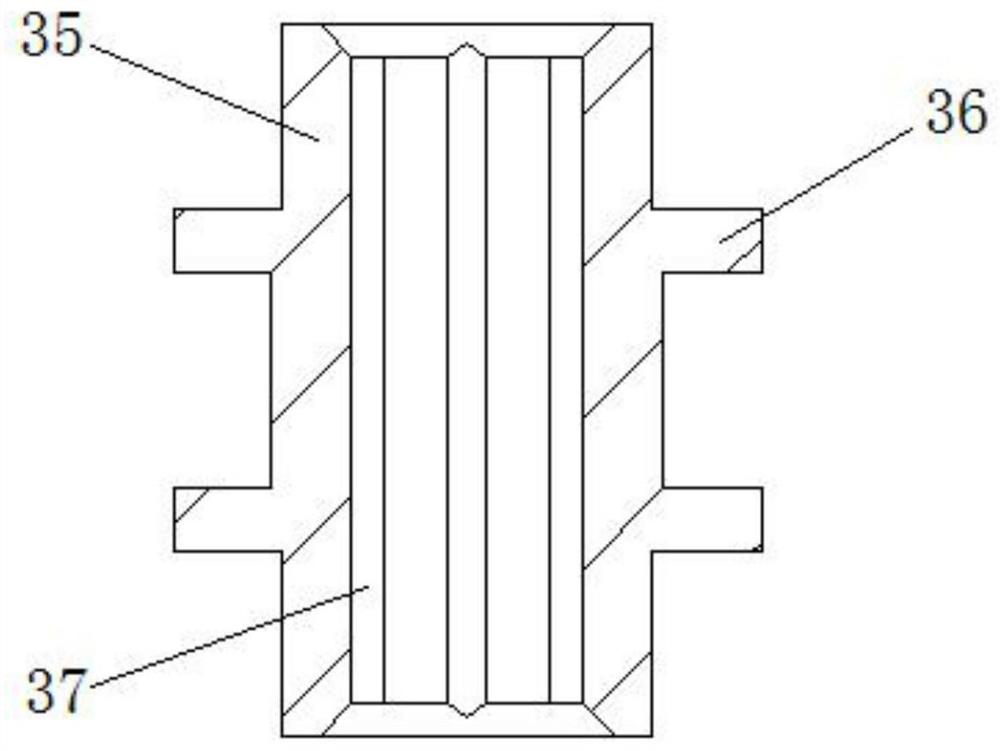

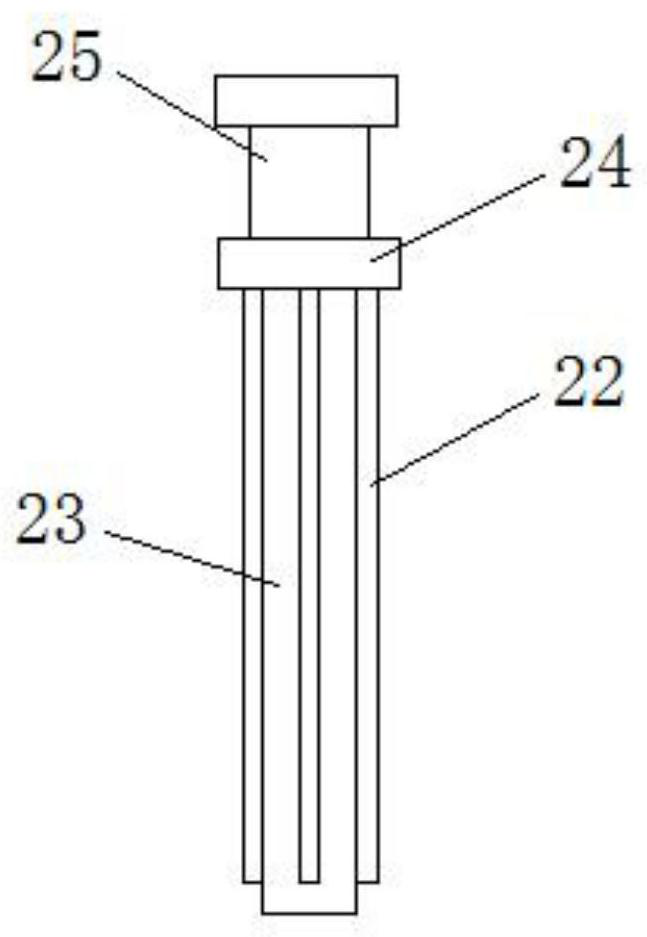

[0025] Example 1: Such as Figure 1-6 As shown, the specific embodiment employed the following technical solution: a centrifugal pump housing processing clamp, including a fixed frame 1, a compression mechanism 2, a rotating mechanism 3, and a clamping mechanism 4, and a fixed frame 1 is mounted. The rotating mechanism 3 and the clamping mechanism 4, the rotating mechanism 3 is connected to the compression mechanism 2, and the compression mechanism 2 is connected to the clamping mechanism 4.

[0026] Wherein, the fixed frame 1 includes a bottom plate 11, a support plate 12, a fixing plate 13, a slide groove 14, a screw hole 15, a positioning rod 16, a rectangular frame 17, a rotating tray 18, and a connecting plate 19, and a fixed plate 13 is provided. Two connecting plates 19 are fixed between the bottom plate 11 and the fixing plate 13, where two support plates 12 are fixed to the side walls of the connecting plate 19, and the middle of the fixing plate 13 is embedded with a rota...

Embodiment 2

[0035] Example 2: The press-fitting clamp 47 end in the first embodiment mounts the centrifugal pump grip model, and is activated by the two half-model settings, and the secondary rotating shaft 42 is activated. Turning, the external thread 44 is threaded with the threaded sleeve 45, and the two press-fitting hooks 47 are close to each other, and the two half modes are close to each other, and the two semi-molds are sandwiched on both sides of the centrifugal pump. On, thereby effectively positioning the centrifugal pump, can be treated more comprehensively, and the outer wall of the centrifugal pump is more comprehensive, and the friction coaxial is connected between the secondary motor 41 output shaft and the secondary shaft 42 can effectively avoid the clamping action overload. , The case where the second motor 41 or external thread 44 is damaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com