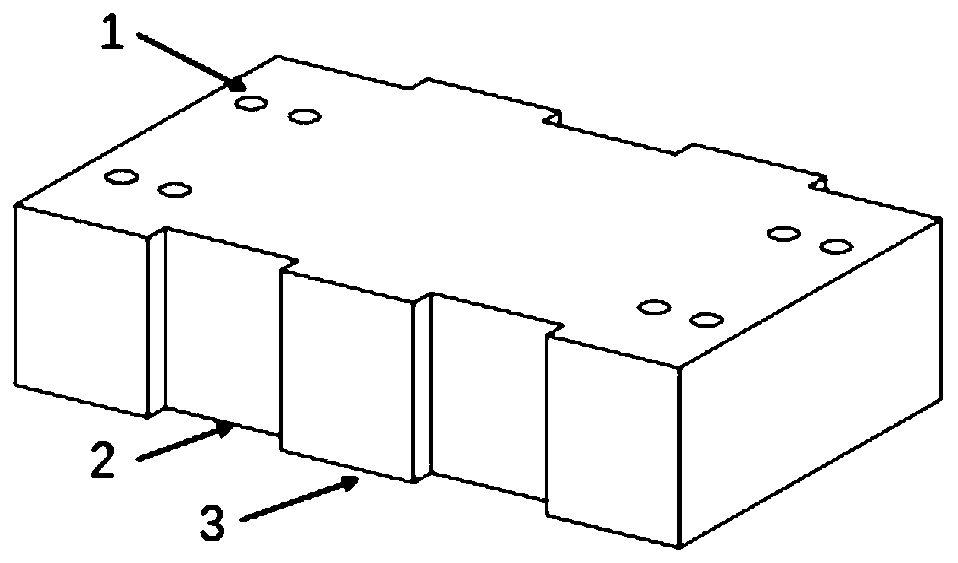

Construction method of foundation pit supporting structure of prefabricated reinforced concrete combined support

A foundation pit support and prefabricated assembly technology, which is applied in infrastructure engineering, excavation, construction, etc., can solve the problems of increasing the cost of construction waste treatment, the inability to effectively recycle steel beams, and the long time of concrete, etc., to achieve high rigidity, The effect of light weight and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further elaborated below by specific examples.

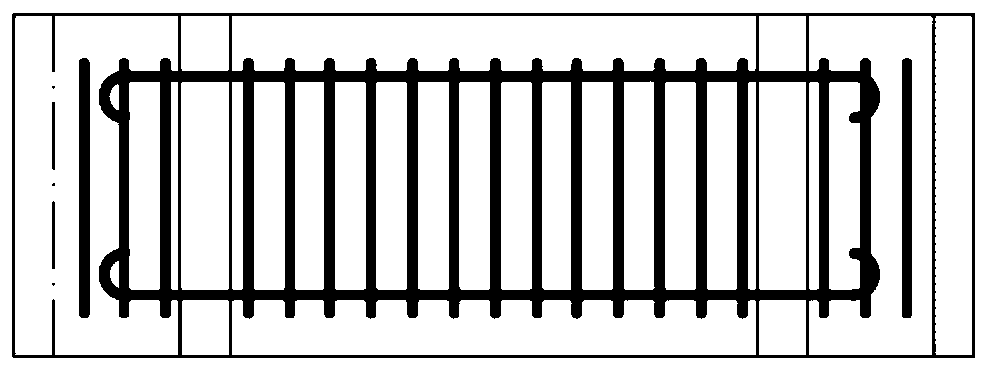

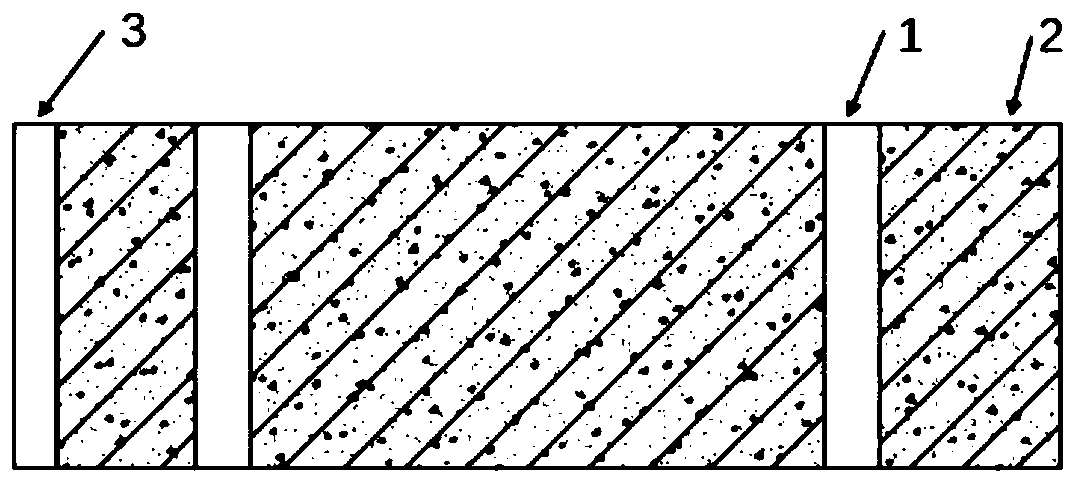

[0042] A foundation pit supporting method of a prefabricated assembled steel-concrete composite support as shown in the accompanying drawing, comprising the following steps:

[0043]Step 1, referring to Fig. 10(a), a circle of steel purlins 10 is set along the surrounding wall of the foundation pit, and the front row of steel columns and the rear row of steel columns are respectively driven into the front and rear sides of the foundation pit along the vertical direction. Column 8, front steel column and rear steel column 8 respectively comprise a plurality of steel columns arranged at left and right intervals; The distance between them is 6-9m, and the distance between the two front and rear steel columns 8 corresponding to each other is 6-9m, so that the structure design is reasonable, the plane layout is reasonable, and the construction is convenient.

[0044] Step 2, welding a steel corbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com