Cart for logistics carrying

A logistics handling and trolley technology, applied to trolleys, multi-axis trolleys, motor vehicles, etc., can solve the problems of inconvenient express delivery on shelves and no lifting function, so as to facilitate the placement of goods, speed up, and ease of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

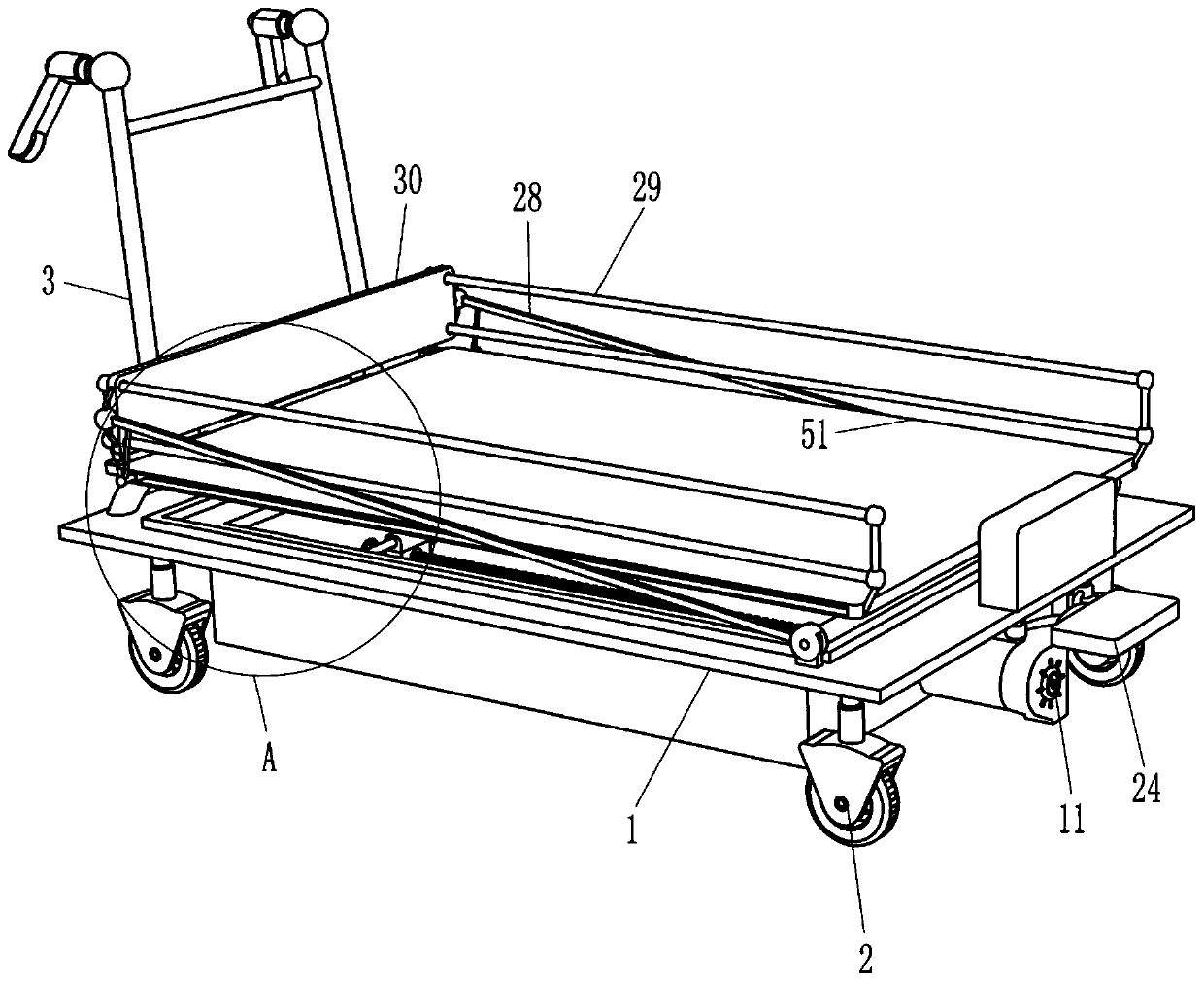

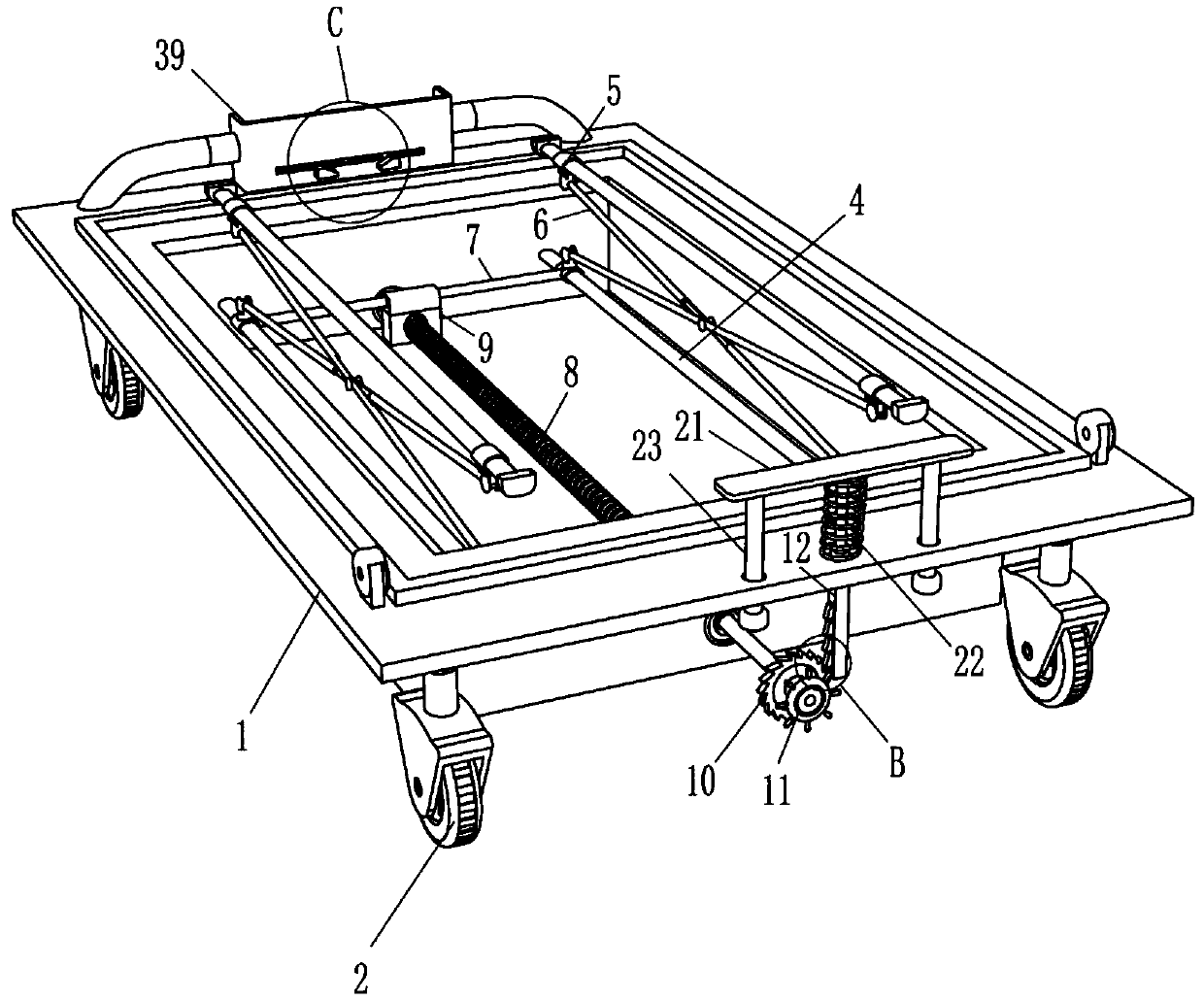

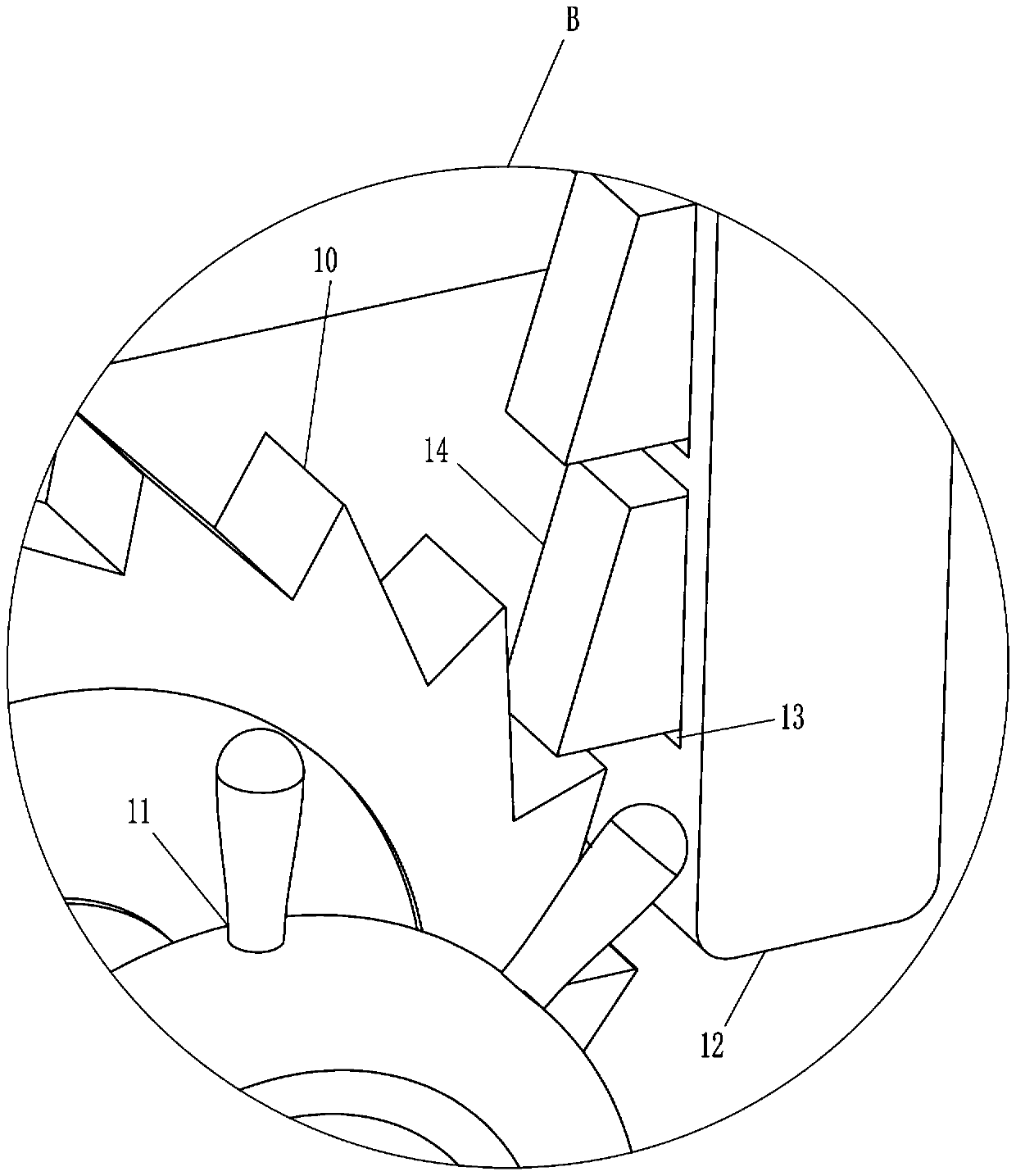

[0024] A cart for logistics handling, such as figure 1 , 2 , 3 and 4, including installation box 1, wheel 2, push handle 3, lifting assembly and transmission assembly, the bottom of installation box 1 is provided with wheel 2, the left side of installation box 1 is provided with push handle 3, and installation box 1 is provided with The lifting assembly is lifted and lowered by sliding, and the lower part of the installation box 1 is provided with a transmission assembly that is driven by rotation, and the transmission assembly cooperates with the lifting assembly.

[0025] Such as figure 2 As shown, the lifting assembly includes a first square guide rod 4, a sliding sleeve 5, a placement plate 51, a telescopic frame 6, a cross bar 7, a screw rod 8 and a nut 9, and the front and rear sides of the installation box 1 are provided with first Square guide rod 4, the first square guide rod 4 is slidably connected with a telescopic frame 6 through a sliding sleeve 5, and the uppe...

Embodiment 2

[0031] On the basis of Example 1, such as Figure 5 Shown, in order to place goods better, also include the second slider 26, the second connecting rod 27, the swing bar 28, the second square guide rod 29 and the push plate 30, all have slides on the front and rear sides of the placement plate 51. Slot 25, all sliding type is provided with the second slide block 26 in the chute 25, the second slide block 26 outside rotation type is provided with the second connecting rod 27, and the right side rotation type of installation box 1 top is provided with fork 28, fork 28 left parts are rotationally connected with the second connecting rod 27, and the front and rear sides of the top of the placement plate 51 are all fixedly connected with the second square guide rod 29 by bolts. The top is rotatably connected with the push plate 30 .

[0032] Such as Figure 6 , 7 , 8 and 9, in order to allow the placement plate 51 to reset better, it also includes a bevel gear 31, a rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com