Steel wavy floor for container

A container and corrugated technology, applied in the field of steel corrugated floors, can solve the problems of a large amount of labor and wooden floors that are difficult to reduce weight, and achieve the effects of high use strength, reduced transportation weight, and labor and time savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

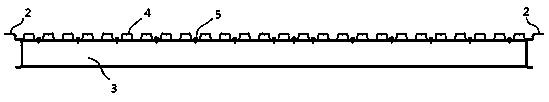

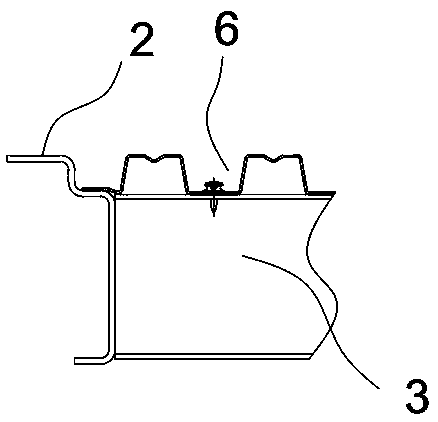

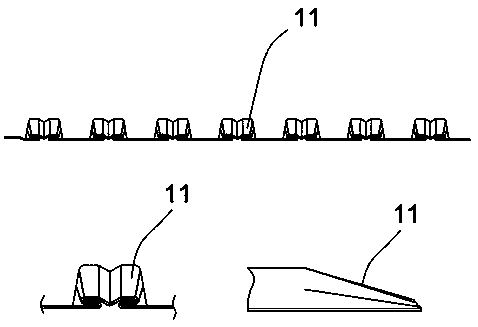

[0029] see Figure 1-6 , according to an embodiment of the present invention, a steel corrugated floor for containers is composed of a corrugated floor integral 1 and a C-shaped keel 3, and the two sides of the corrugated floor integral 1 and the joint 2 between the container body and the corrugated floor are arranged There are 3 mm protrusions, and the whole corrugated floor 1 is evenly provided with several trapezoidal wave crests 4, and the middle position of the top of the wave crests 4 is provided with a groove-shaped reinforcing rib 10, and the entrance end of the corrugated floor 1 is provided with a slope 11 , the bottom of the corrugated floor 1 is evenly arranged with several C-shaped keels 3 perpendicular to the direction of the crest 4, and the troughs 6 between the crests 4 of the C-shaped keel 3 are fixed to the upper end of the C-shaped keel 3 by nails 5 connect.

[0030] Through the above scheme of the present invention, the corrugated floor overall 1 and the ...

Embodiment 2

[0032] Specifically, the base width of the crest 4 is 51mm; the width of the trough 6 is 37.5mm; is 100 degrees; the concave angle of the reinforcing rib 10 is 120 degrees, and the depth is 4mm.

[0033] Through the above scheme of the present invention, the whole corrugated floor 1 adopts the design of evenly arranged wave peaks 4 and troughs 6, and cooperates with the reinforcing ribs 10 arranged on the wave crests 4 to increase the load bearing of the whole corrugated floor 1, which can 100% meet the 7260KG standard.

Embodiment 3

[0035] Specifically, the interval between the C-shaped keels 3 is 400-420mm, and the C-shaped keels 3 are made of steel; The thickness of the whole 1 is 1.6mm.

[0036] Through the above scheme of the present invention, the C-shaped keels 3 arranged at even intervals ensure the load bearing of the floor while reducing the number of C-shaped keels 3. The C-shaped keels 3 and the corrugated floor as a whole are made of steel, with high strength and heavy load bearing , not easy to damage, reducing manufacturing costs and operation and maintenance costs; zinc-alcoholic aluminum alloy coating processing can prevent corrosion hazards caused by friction between forklifts and goods.

[0037] In order to facilitate the understanding of the above-mentioned technical solution of the present invention, the working principle or operation mode of the present invention in the actual process will be described in detail below.

[0038] In practical application, the C-shaped keel 3 is evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com