Rock foundation core wall earth-rock dam under dam emptying pipe laying device

A technology for earth-rock dams and foundation cores, applied in dams, barrages, water conservancy projects, etc., can solve the problems of inability to ensure the integrity of the anti-seepage body, piping damage, etc., to avoid piping risks, reduce project costs, and simplify energy dissipation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

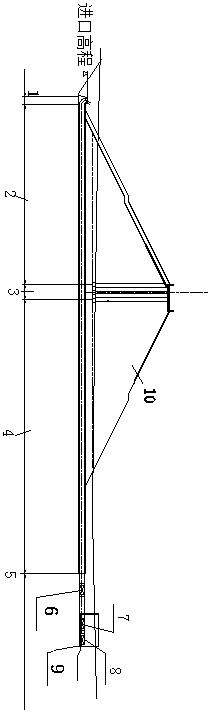

[0024] In order to overcome the existing problem that the integrity of the anti-seepage body cannot be guaranteed, and when it is not handled properly, it is easy to cause piping damage along the outside of the pipeline. The present invention provides such figure 1 Shown is a device for venting buried pipes under the rock foundation core wall earth-rock dam. This invention adopts the downstream conical energy dissipation valve technology, which simplifies the energy dissipation work, solves the energy dissipation problem more effectively, and avoids the construction risk of the tunnel scheme. , reducing the project cost and speeding up the progress.

[0025] A device for emptying buried pipes under a rock foundation core wall earth-rock dam, including an inlet elevation, an inlet section 1, a bedrock buried pipe section 2 in front of the core wall, a core wall bottom section 3, a bedrock buried pipe section 4 behind the core wall, an inspection valve 7, Energy dissipation valv...

Embodiment 2

[0029] On the basis of Embodiment 1, in this embodiment, the inlet of the inlet section 1 is a shaft type, and is set as a horn-shaped inlet.

[0030] The inlet elevation is set at the bottom of the reservoir, and is higher than the sedimentation elevation and not less than the minimum submerged depth of the pressurized water inlet.

[0031] The inlet section 1 is connected with the bedrock buried pipe section 2 in front of the core wall through an elbow, and the bending angle of the elbow is 90°-180°.

[0032] The inlet section 1 provided in the present invention: the inlet is a vertical shaft type, and a trumpet-shaped inlet is set. The inlet elevation is close to the bottom of the reservoir. At the same time, it should be comprehensively demonstrated in conjunction with the sediment and silt situation. If it is lower than the sediment deposition elevation, it should be combined with a model test. To determine its sand removal effect and operation mode, the inlet section 1 u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com