A Method for High Drilling Speed Rotary Steerable System to Realize High Buildup Rate

A technology of rotary steering and system realization, which is applied in drilling equipment and methods, automatic control systems for drilling, directional drilling, etc. The effect of drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the drawings and embodiments.

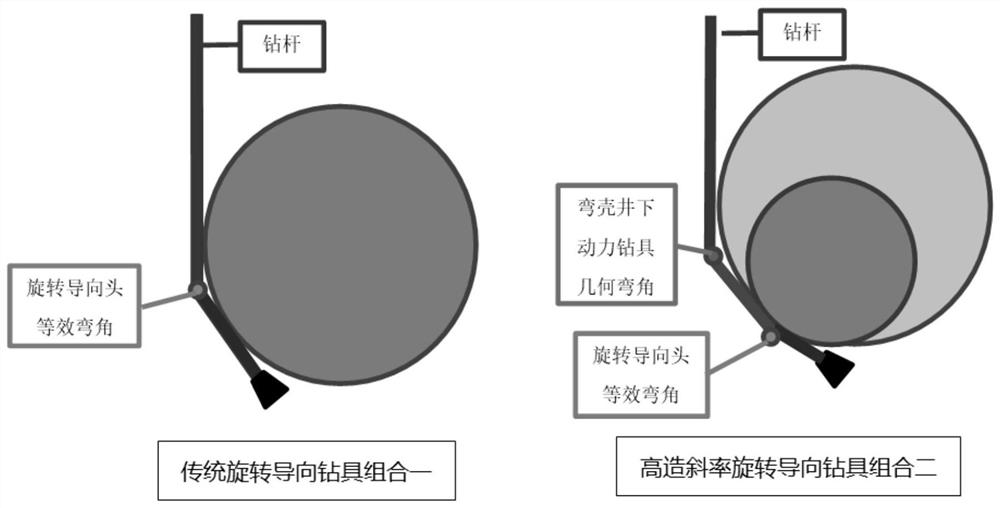

[0023] A method for achieving high build-up rate of a high-speed rotary steerable system, the drill tool assembly used includes a drill bit, a rotary steerable head, a lower stabilizer, a bent-shell downhole motor, a MWD and an upper stabilizer that are sequentially connected in series . The curved casing downhole dynamic drilling tool may be a curved casing screw drilling tool or a curved casing turbodrilling tool;

[0024] Described method comprises the following steps:

[0025] Step 1. Assemble the drill string according to the above sequence and drop it to the bottom of the well;

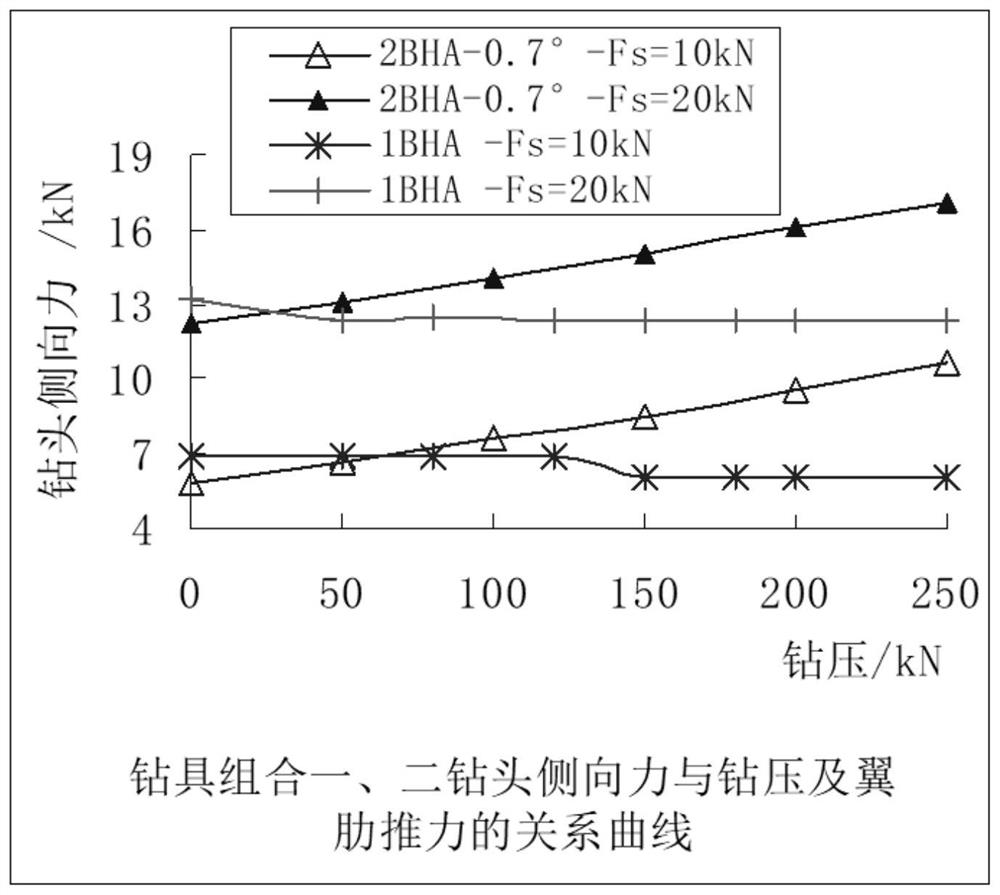

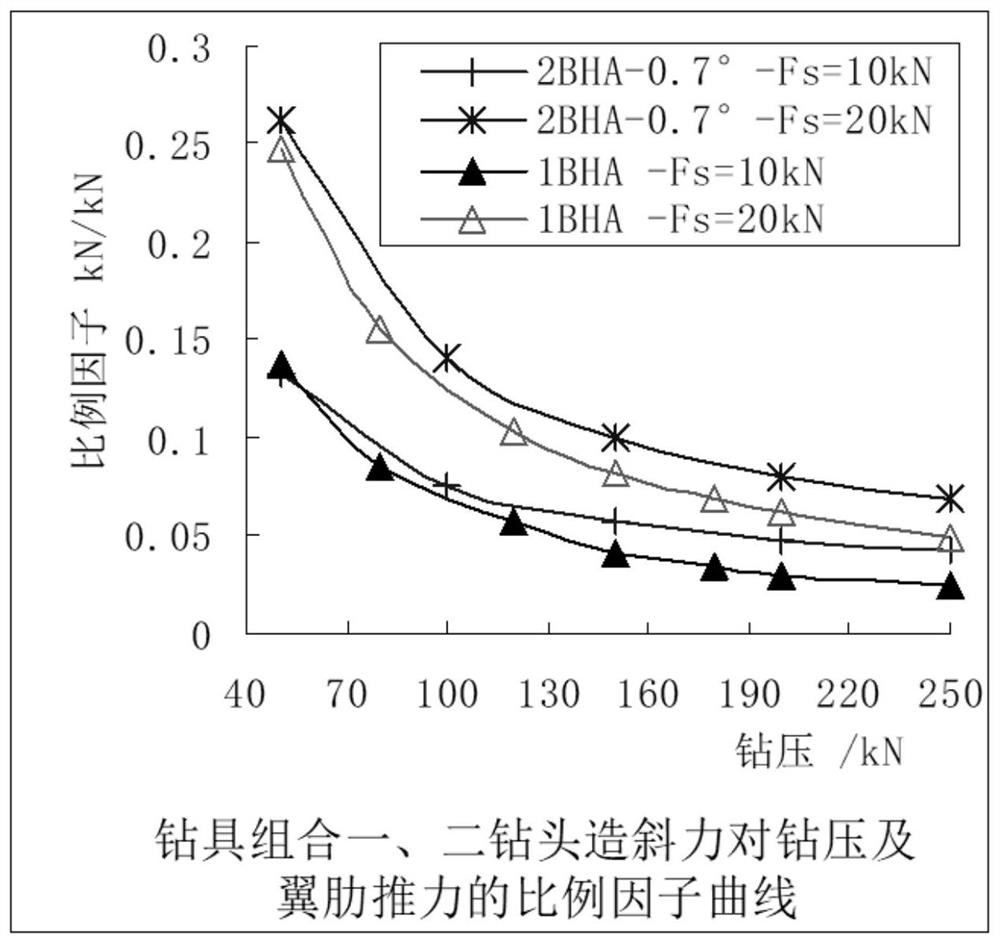

[0026] Step 2: Drilling mud is circulated, and the rotary steering head performs rotation-steering-directional drilling as required. Since the drilling tool has a curved shell downhole power drilling tool, the speed of the drill bit is the sum of the speed of the surface drilling di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com