Brake calliper of a disk brake for motor vehicles

A disc brake and brake caliper technology, which is applied to the components of the brake, the type of the brake, the brake on the axial direction, etc., which can solve the problems of extending the brake caliper and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation plan

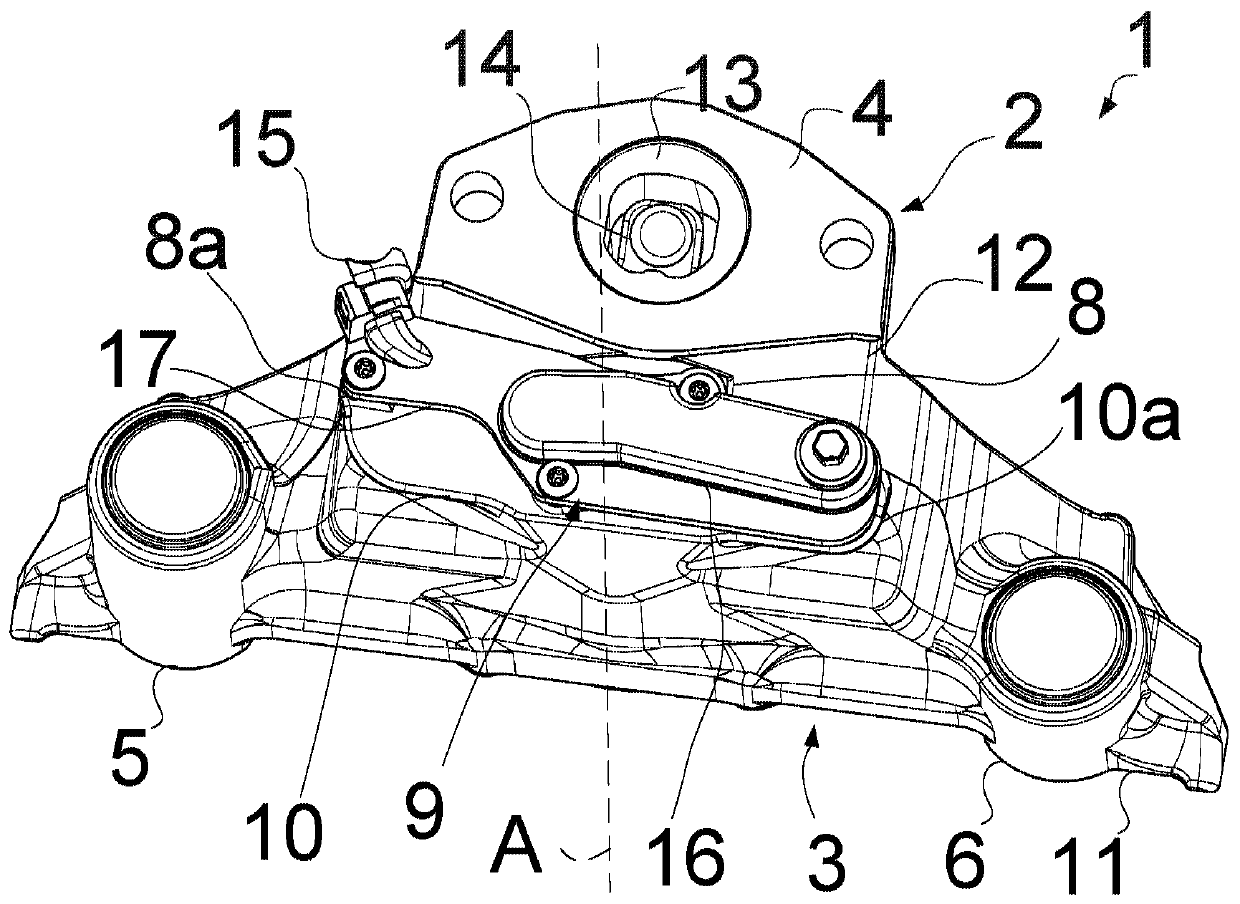

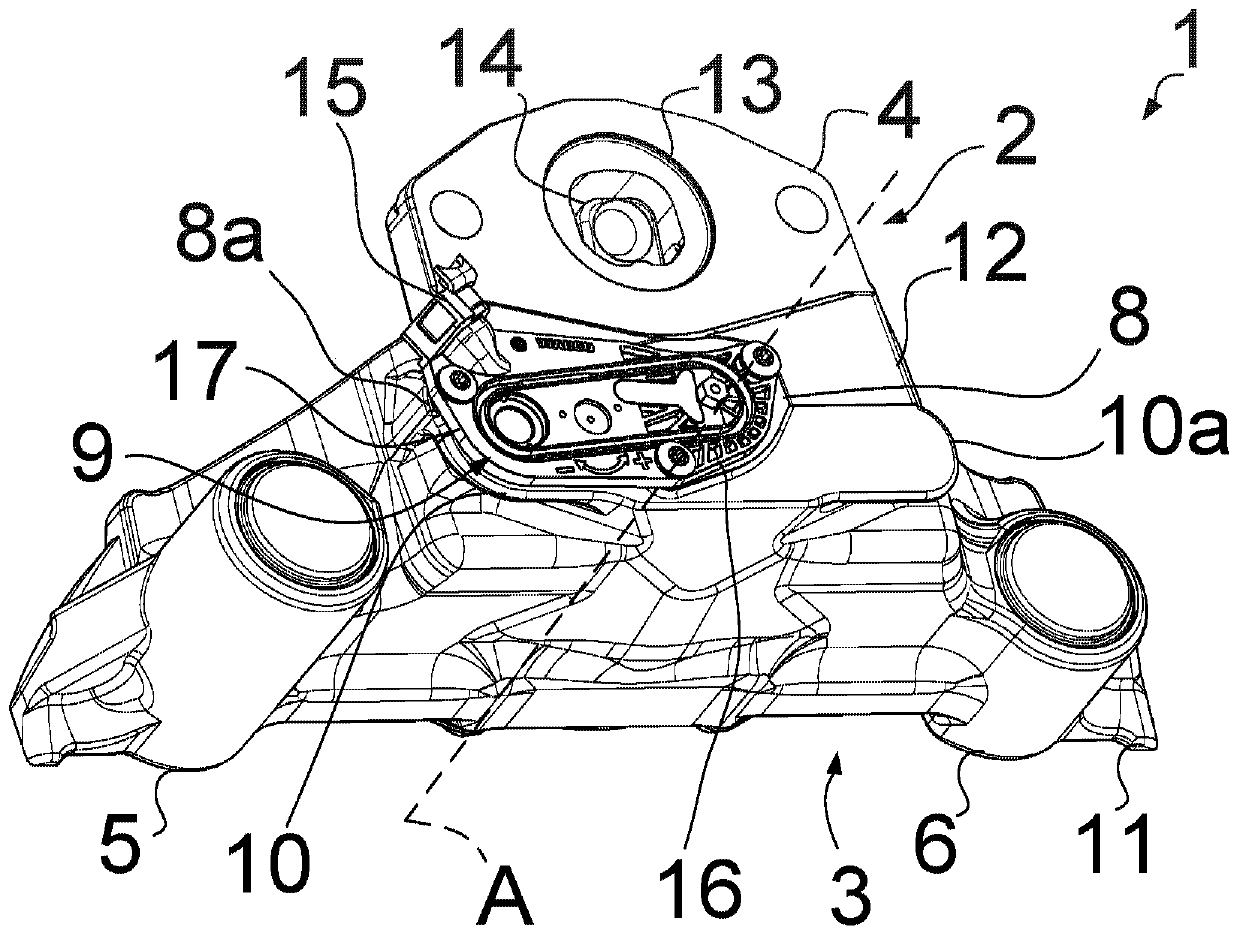

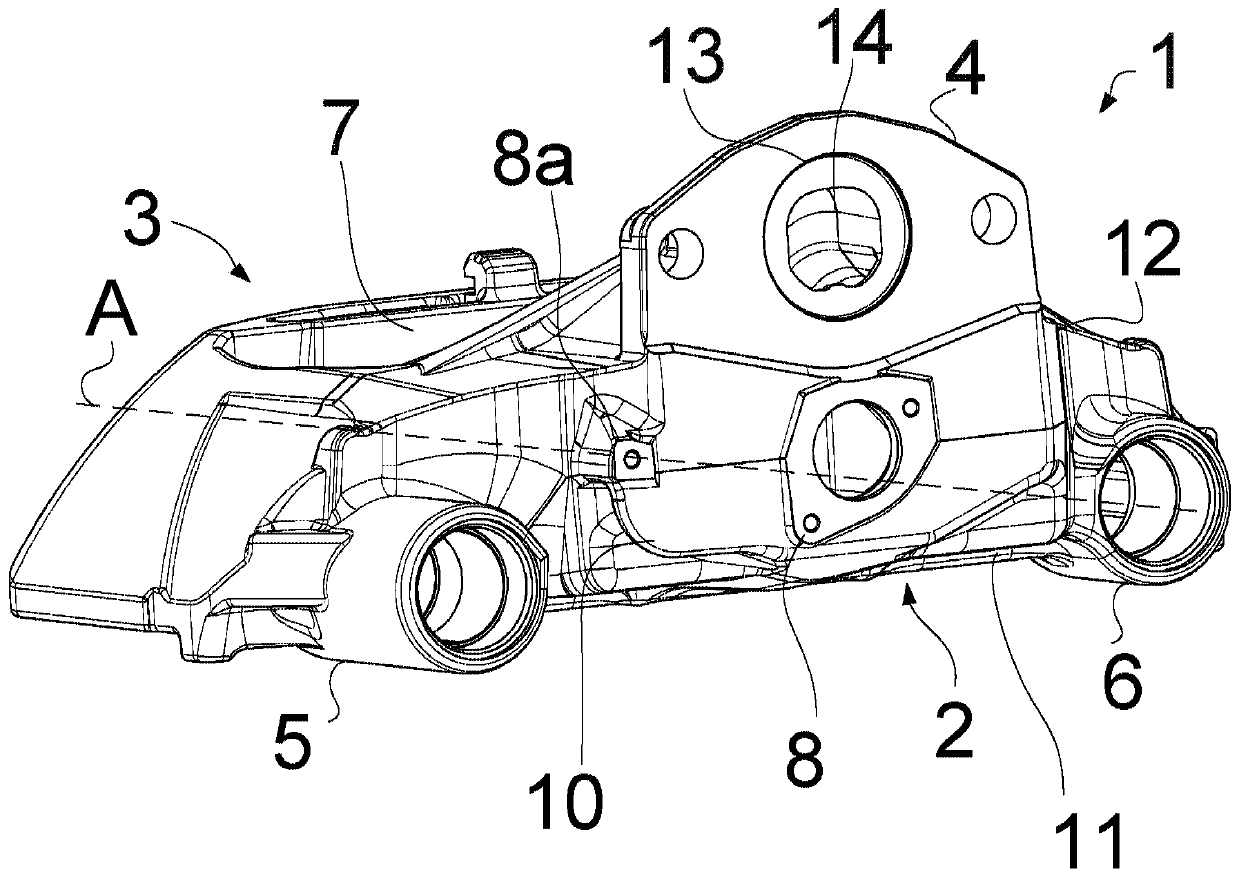

[0020] figure 1 The brake caliper 1 on the application side is shown. The brake caliper 1 is made of cast iron and has a brake cylinder flange surface 4 on the contact side 2 . An opening 13 for actuating a torsion bar 14 is arranged in the middle of the brake cylinder flange surface 4 . Between the pressure side 2 and the rim side 3, the brake caliper 1 has a brake disc opening 7 for receiving a not shown brake disc (cf. image 3 ). During the pressing process, the torsion bar 14 presses the brake disc via the pressing device. Two sliding sleeves 5 , 6 arranged axially parallel to the axis A of the brake caliper 1 move the brake caliper 1 axially on a not shown brake carrier during the braking process. Radially below the brake cylinder flange surface 4, in the direction of the first sliding sleeve 5 and the second sliding sleeve 6, the brake caliper 1 has a caliper housing 11 for receiving the flange surface 8, Subassembly 12 of 8a....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com