Vehicle lamp

A technology of car lights and photons, applied in the field of lighting, to achieve the effect of clear low beam cut-off line, high center brightness, and overcoming effects that cannot be achieved at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

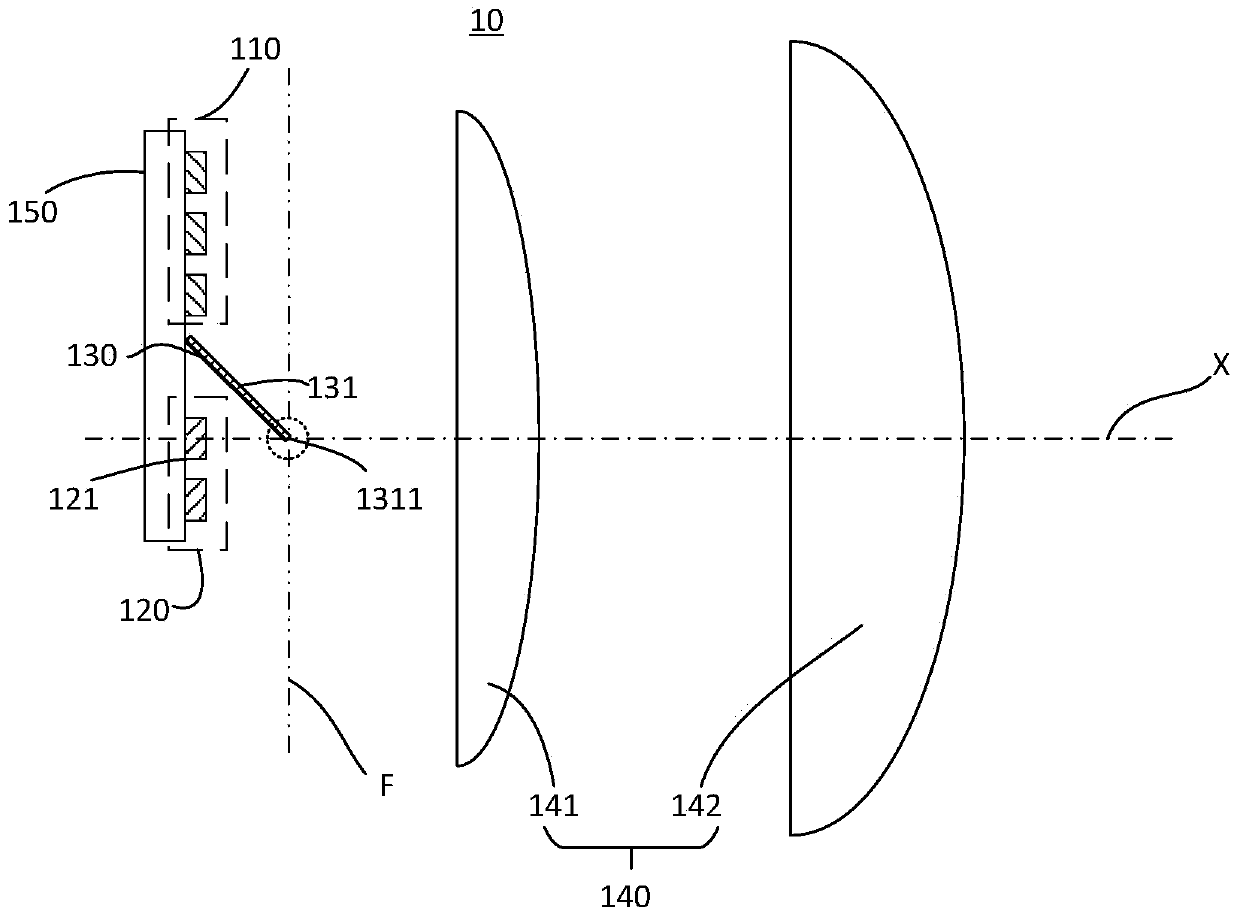

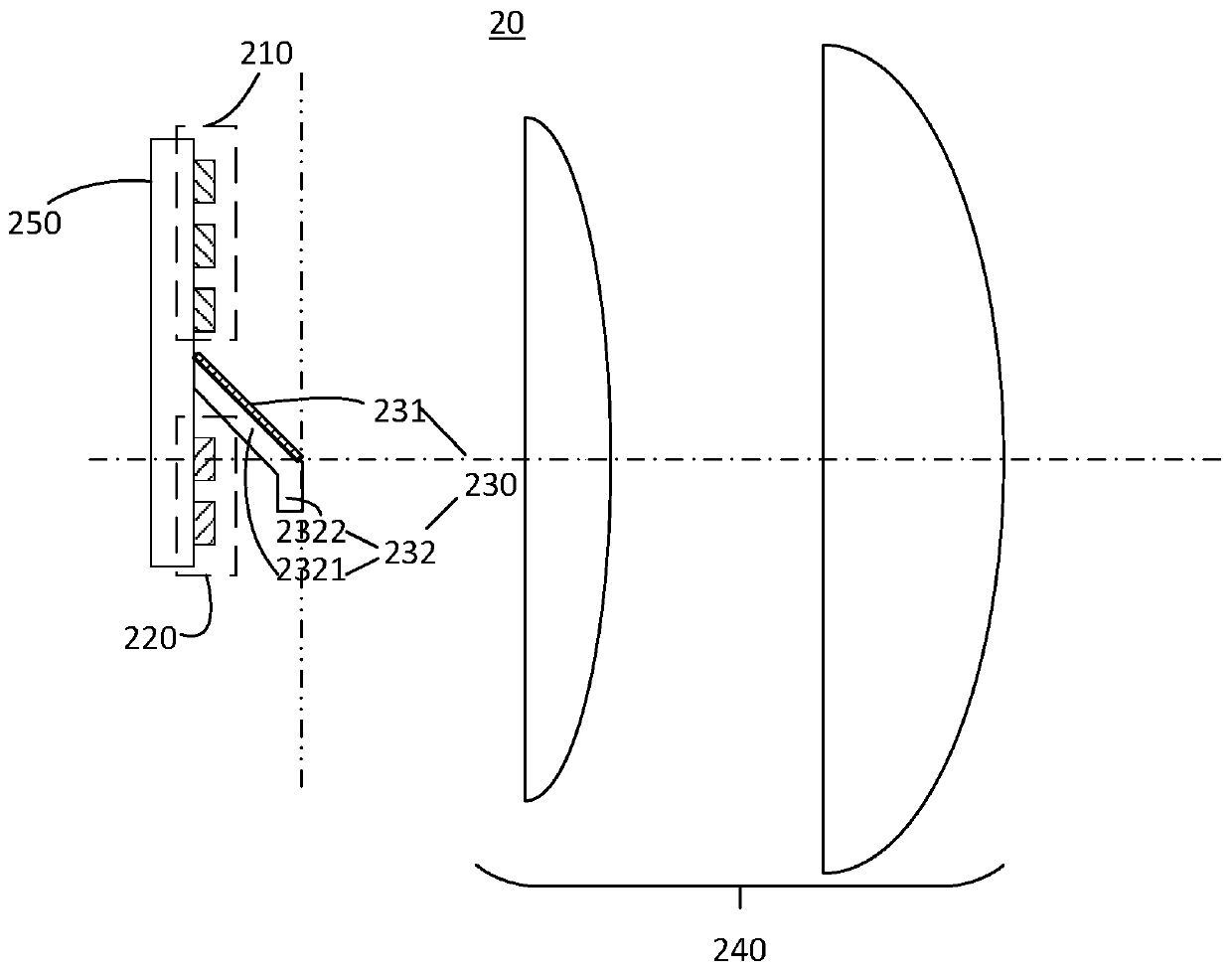

[0052] Both the carriers of Embodiment 2 and Embodiment 3 include a "transparent extension" arranged on the light output path of the second light-emitting sub-array. In the present invention, the projection of the transparent extension on the second light-emitting sub-array can be completely Covering the light-emitting surface of the second light-emitting sub-array. Such as Figure 5As shown, it is a front view of a vehicle lamp of the present invention (viewing angle against the direction of outgoing light). It includes a first light-emitting sub-array 1 , a second light-emitting sub-array 2 , a light-shielding surface 3 and a carrier 4 . Wherein, the second light-emitting sub-array 2 is behind the transparent extension part of the carrier 4, so it is represented by a dotted line.

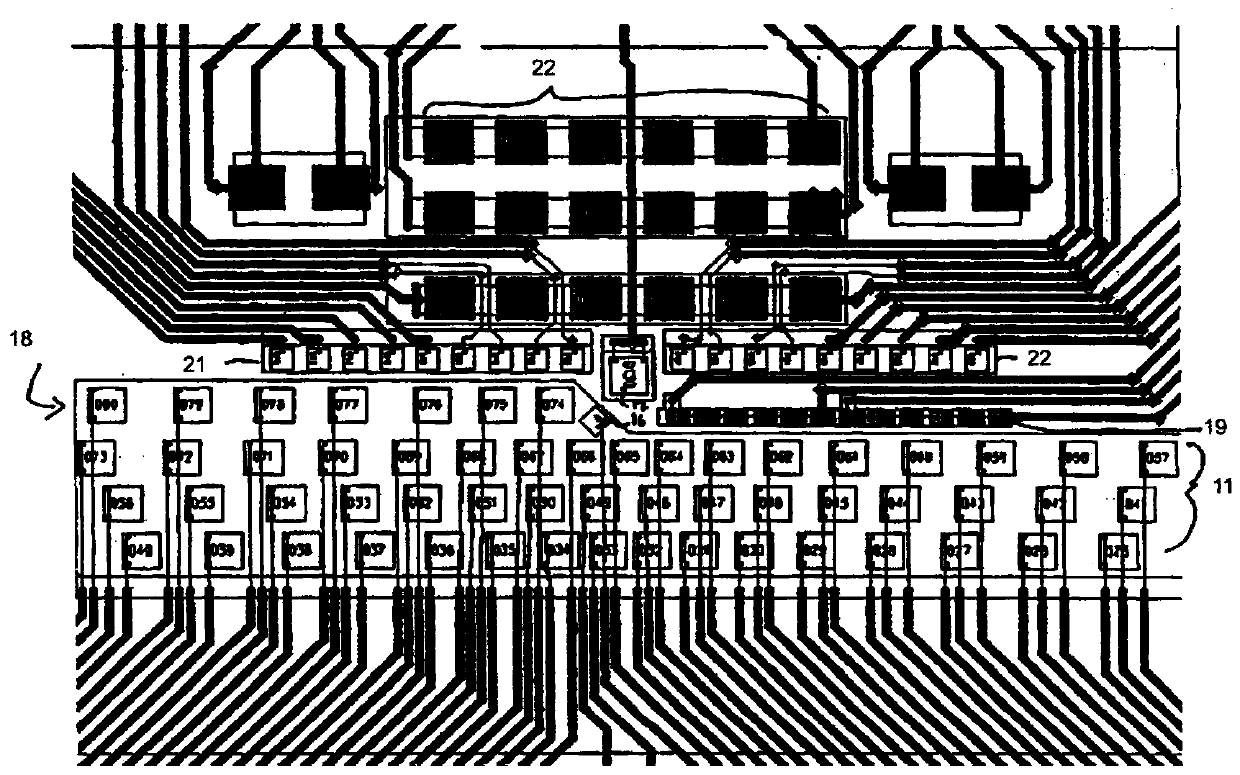

[0053] In each of the embodiments listed above, both the first light-emitting sub-array and the second light-emitting sub-array are LED arrays, and the LED arrays are controlled by corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com