Ultra-deep sampling device for high turbidity water near the liquid surface and its application method

A sampling device and liquid surface technology, which is applied in the field of ultra-deep sampling devices for high turbidity water near the liquid surface, can solve the problems of equipment performance limitations, difficulty in collecting samples, easy damage to equipment, etc., and achieve the goal of eliminating head restrictions and reducing energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

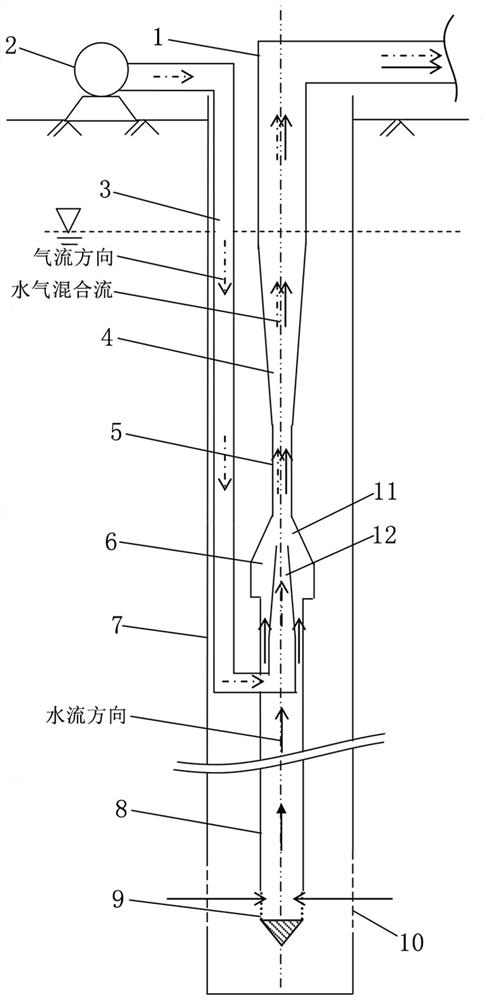

[0022] Example 1: An ultra-deep sampling device for high turbidity water near the liquid surface.

[0023] Such as figure 1 As shown, the ultra-deep sampling device facing the liquid surface of the present invention includes a jet 11 , an air pump 2 , a water inlet pipe 8 and a flower net pipe pendant 9 .

[0024] The ejector 11 can adopt the ejector sold on the market, and its structure comprises suction chamber 6, the nozzle 12 that is arranged in the suction chamber 6, the throat pipe 5 that is connected to the upper port of the suction chamber 6, joins with the upper port of the throat pipe 5 Diffusion section 4. A water outlet pipe 1 is connected to the upper port of the diffuser end 4 of the jet, and the other end of the water outlet pipe 1 leads to the ground and is connected with a sampling device arranged on the ground. The wall of the water outlet pipe 1 is marked with scale marks representing the length of the water outlet pipe 1 .

[0025] The air pump 2 is set ...

Embodiment 2

[0029] Embodiment 2: A method of using an ultra-deep sampling device for high turbidity water near the liquid surface.

[0030] The use method of the ultra-deep sampling device for high turbidity water near the liquid surface of the present invention comprises the following steps:

[0031] 1. Measure the distance between the well water level in the well to be sampled and the wellhead, and accordingly determine the depth of injection of the ejector 11 in the water well to be sampled, so that the ejector 11 can be submerged below the liquid level of the well water after delivery;

[0032] 2. According to the structural data of the well pipe 7 of the well to be sampled and the measured distance data from the well water surface to the wellhead, respectively calculate the distance between the filter 10 at the lower part of the well pipe and the well water liquid surface and the configuration of the required water inlet pipe length, and intercept the water inlet pipe 8 of correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com