Ultrasonic guided wave multi-damage identification method based on Bayesian updating and Gibbs sampling

A Gibbs sampling, ultrasonic guided wave technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and processing response signals of detection, etc., which can solve problems such as identification and positioning difficulties. , to reduce errors and overcome positioning difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

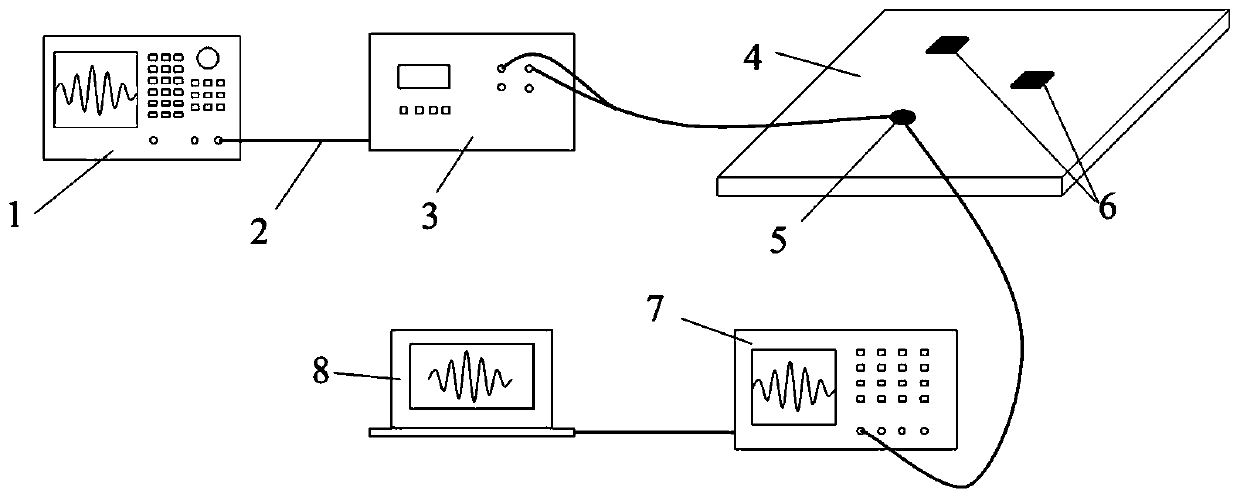

[0082] This embodiment is to apply the present invention to the defect detection of aluminum plate components, figure 1 Schematic diagrams of the equipment, ultrasonic transducers and specimens used in the implementation of this example are given.

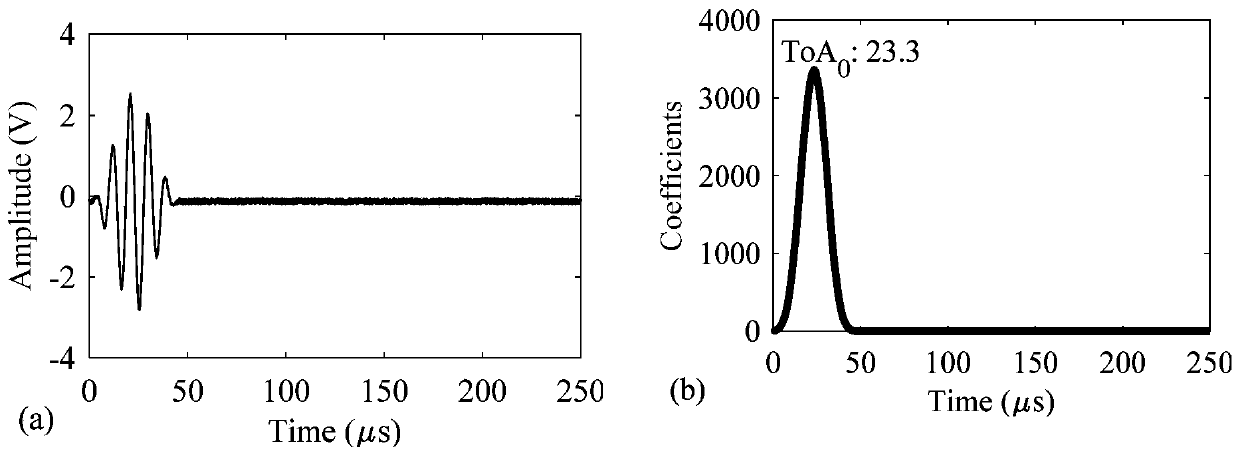

[0083] The excitation signal is a narrow-band five-peak sinusoidal signal modulated by a Hanning window, with a center frequency of 110 kHz. The signal excited by the sensor and the corresponding complex Morlet wavelet transform coefficients are as follows: figure 2 As shown, it can be seen that its departure time is 23.3μs. The detection method used is pulse-echo mode. The lossless and lossy signals are obtained by exciting the aluminum plate in the lossless and lossy state, and the residual signal related to the damage can be obtained by subtracting the two.

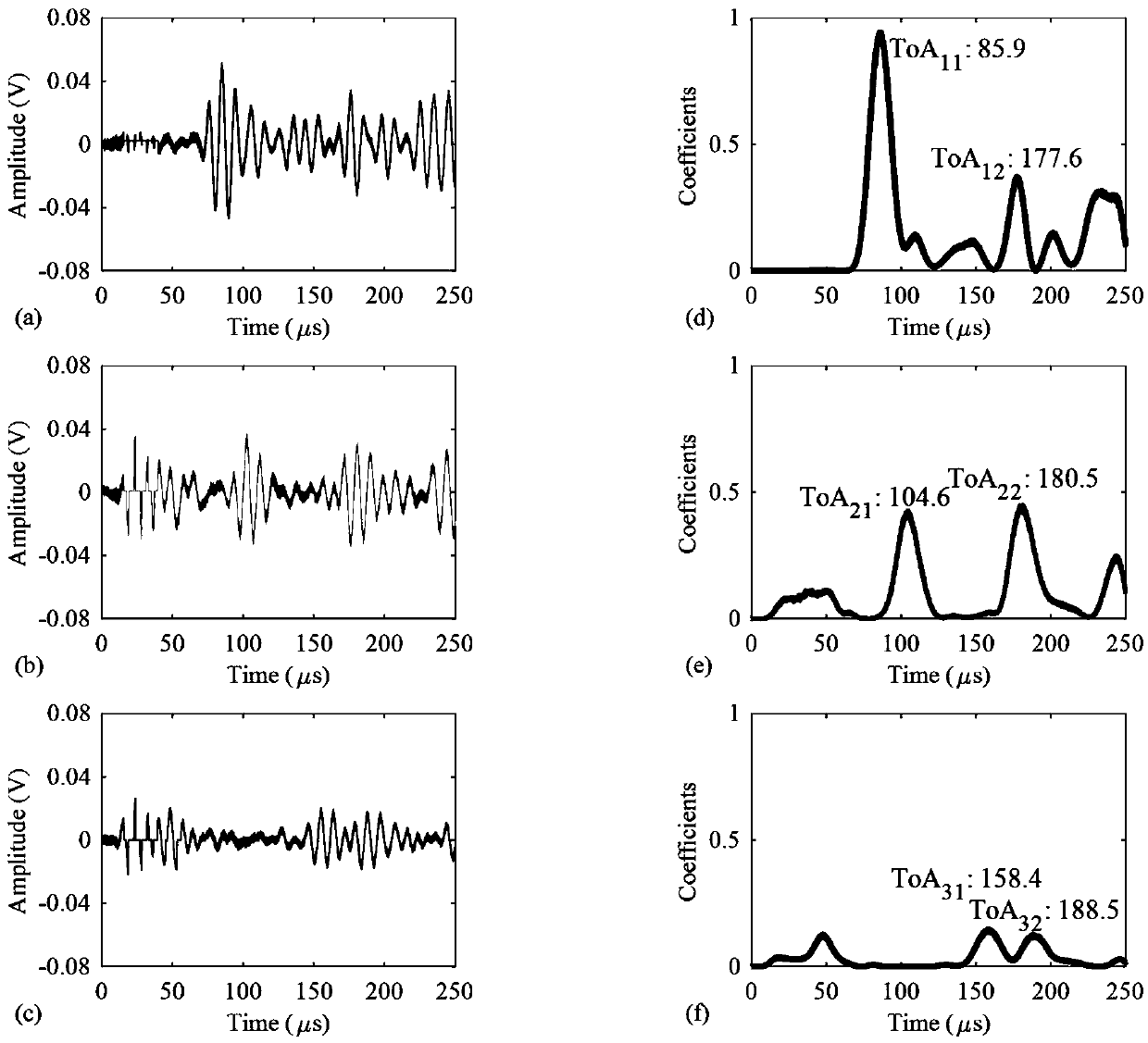

[0084] The first step is specifically: assuming that the two wave packets in the residual signal are identified as signals directly reflected by two damages, and the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com