An mtp wiring device that can meet the needs of high-density wiring of optical fiber distribution boxes

A high-density wiring and optical fiber wiring technology, which is applied in the coupling, optics, and light guide directions of optical waveguides, which can solve the problems of loose wire joints and leakage, and achieve the effect of easy storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

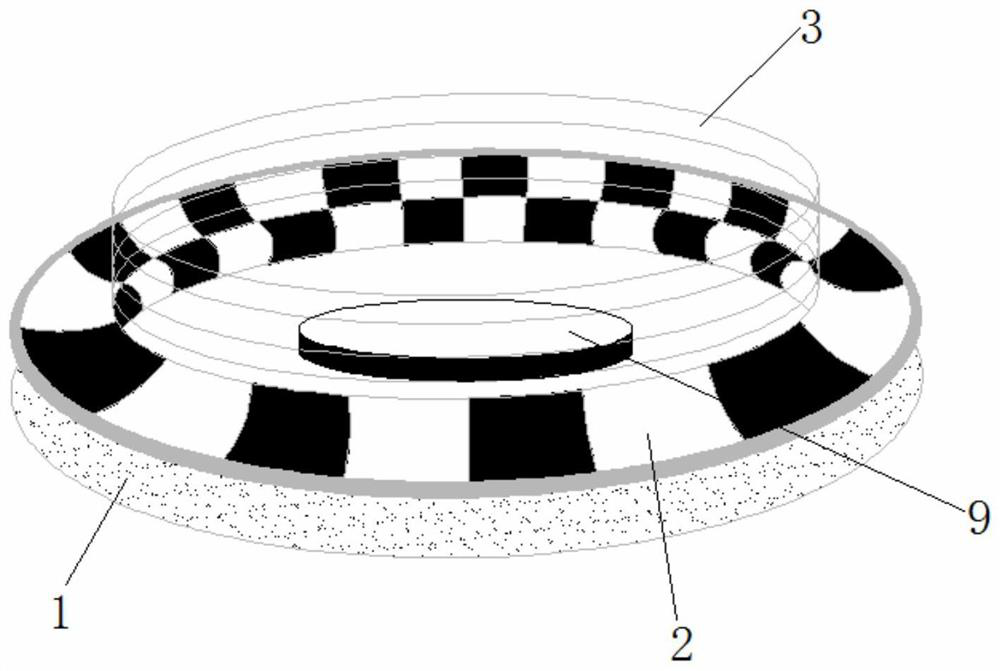

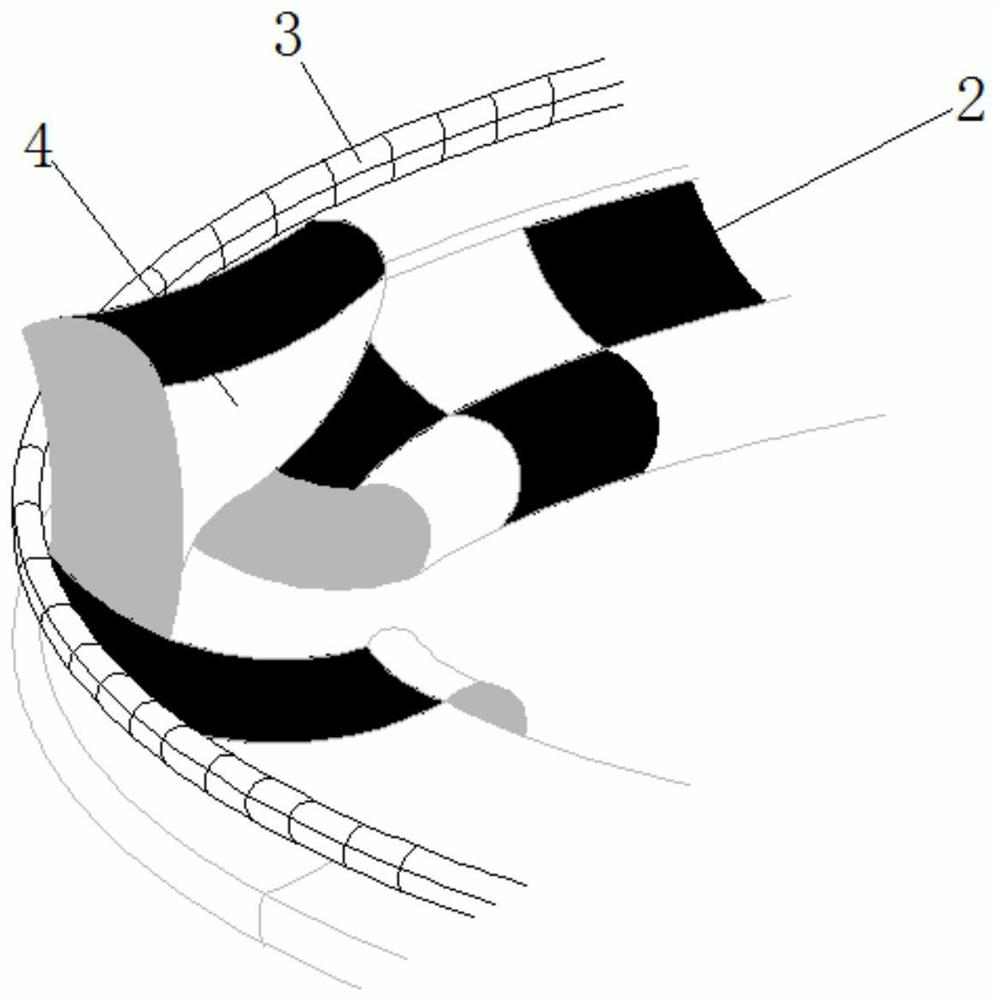

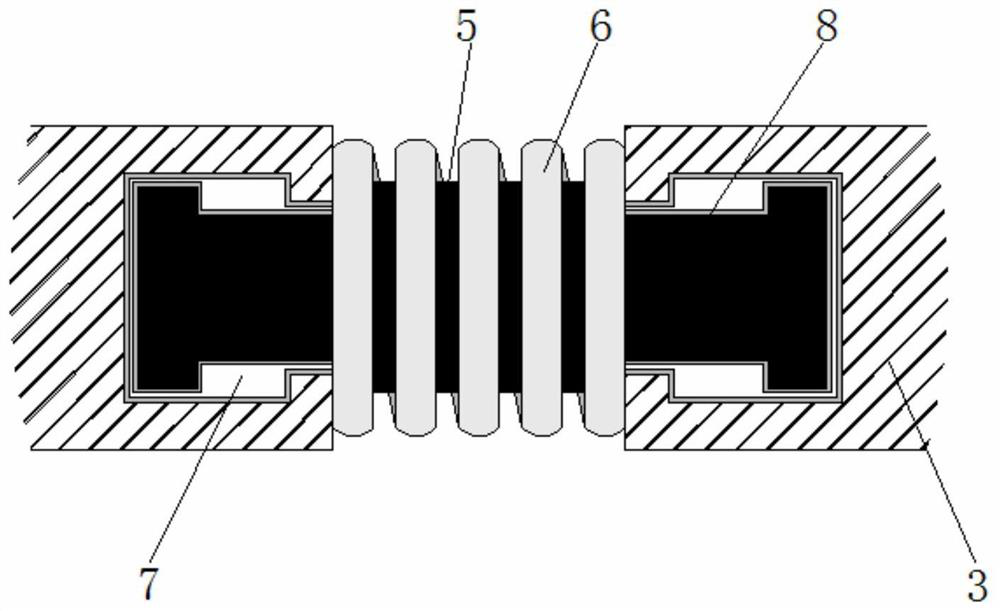

[0031] as attached figure 1 to attach Figure 7 Shown:

[0032] The invention provides an MTP wiring device capable of meeting the high-density wiring requirements of optical fiber distribution boxes, including a base 1, the top of the base 1 is fixedly connected to the bottom of the inner ring 2, and the outer ring of the inner ring 2 is rotatably mounted on a movable The bottom end of block 4, the outside of movable block 4 is movably installed on the inboard of movable ring 3, and the inwall place of movable ring 3 is elastically connected with tension spring 6, and the internal shaft center of inner ring 2 is provided with central axis 9, and central axis The top of 9 is fixedly connected to the bottom of the soft column 10, and the inner ring 2 is provided with a wrapping groove 12, and the bottom of the wrapping groove 12 is fixedly connected to the top of the hollow ring 11, and the side wall of the hollow ring 11 is fixedly connected to the channel pipe 13 The beginn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com