Design method of dissimilar material connecting structure for automobile and connecting structure thereof

A technology of dissimilar materials and connection structures, applied in instruments, electrical digital data processing, geometric CAD, etc., can solve the problems of small stiffness and low strength, achieve lightweight design, improve connection strength, improve fatigue life and energy absorption characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

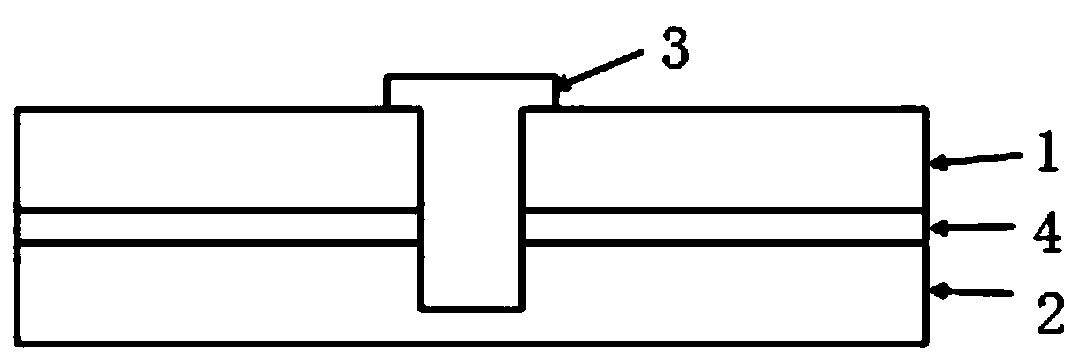

[0058] A connecting structure of dissimilar materials for an automobile of the present invention comprises a base material A board 1 , a base material B board 2 , a mechanical connecting member 3 and a structural adhesive layer 4 . Structural glue is applied between the overlapping parts of base material A and base material B, and the self-piercing riveting process is used to connect base material A and B. The composite connection method overcomes the obvious low strength and stiffness reduction problems of self-piercing riveting relative to spot welding, and uses structural glue to increase the co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap