Full-automatic cooked wheaten food making and blending device for packaged cooked wheaten food selling

A fully automatic, pasta-based technology for coin-operated equipment for dispensing discrete items, coin-operated equipment for dispensing discrete items, coin-operated equipment for controlled dispensing of fluid/granular materials from containers, etc. Direction, can solve the problems that cannot guarantee the stability and service life of the device, affect the inherent nutritional content of food, and poor food processing quality, so as to achieve the effect of universality, reliability and compact process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with embodiment the present invention will be further described.

[0037] In the present invention, packaged pasta refers to pasta, rice noodles, vermicelli, etc. that are wrapped with packaging bags outside the pasta. Before using the device of the present invention, auxiliary materials, such as noodle soup, side dishes, seasonings, etc., need to be pre-placed in the batching mechanism 4 Noodle soup cans, side dish cans, seasoning cans, etc.

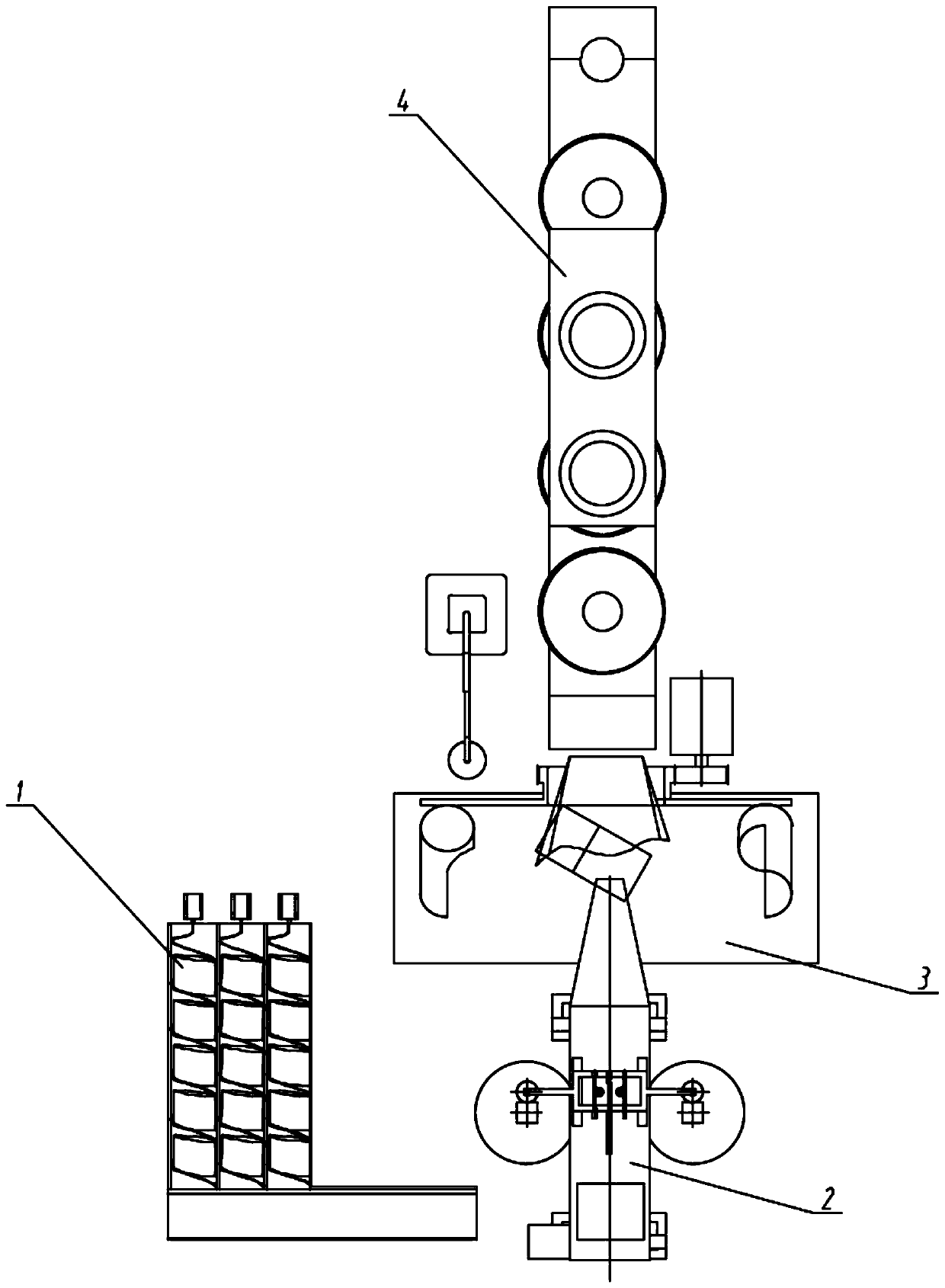

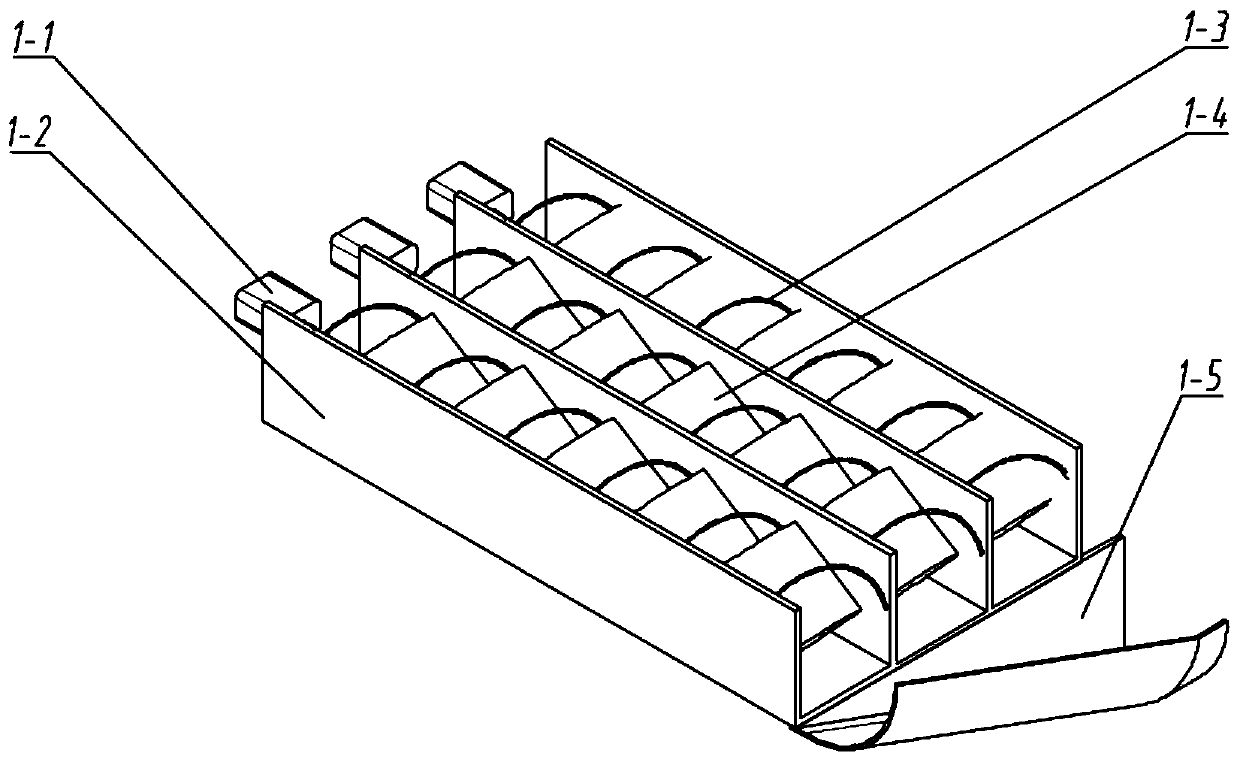

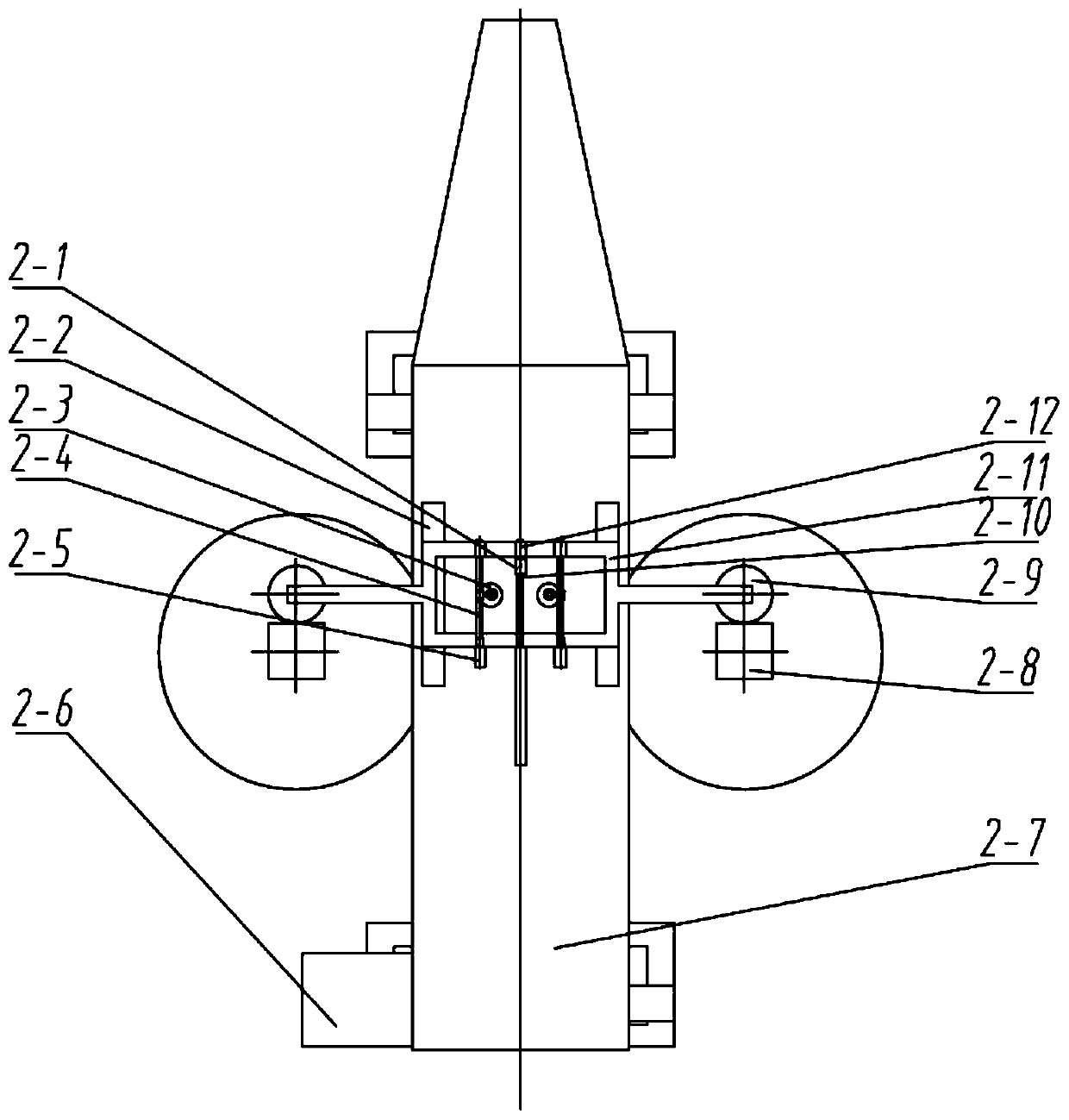

[0038] Such as figure 1 As shown, a fully automatic pasta making and adjusting device for selling pasta with packaging includes an extraction mechanism 1, a packaging removal mechanism 2, a noodle cooking mechanism 3 and a batching mechanism 4, and the ends of the transmission pipelines 1-5 are located at The edge position of the starting end of the conveyor belt 2-7, the end of the conveyor belt 2-7 is connected to the starting end of the transmission pipeline 2-13, and the end of the transmission pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com