Quaternary ammonium salt type hyperbranched polysulfide modified polymer microspheres and preparation method

A technology of polysulfide and quaternary ammonium salt, which is applied in the field of synthesis of porous polymer pellets, can solve the problems of shortening the service life of fungicides, non-recyclable fungicides, and loss of fungicide molecules, so as to achieve safe service life and increase dosage , The effect of simplifying the production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

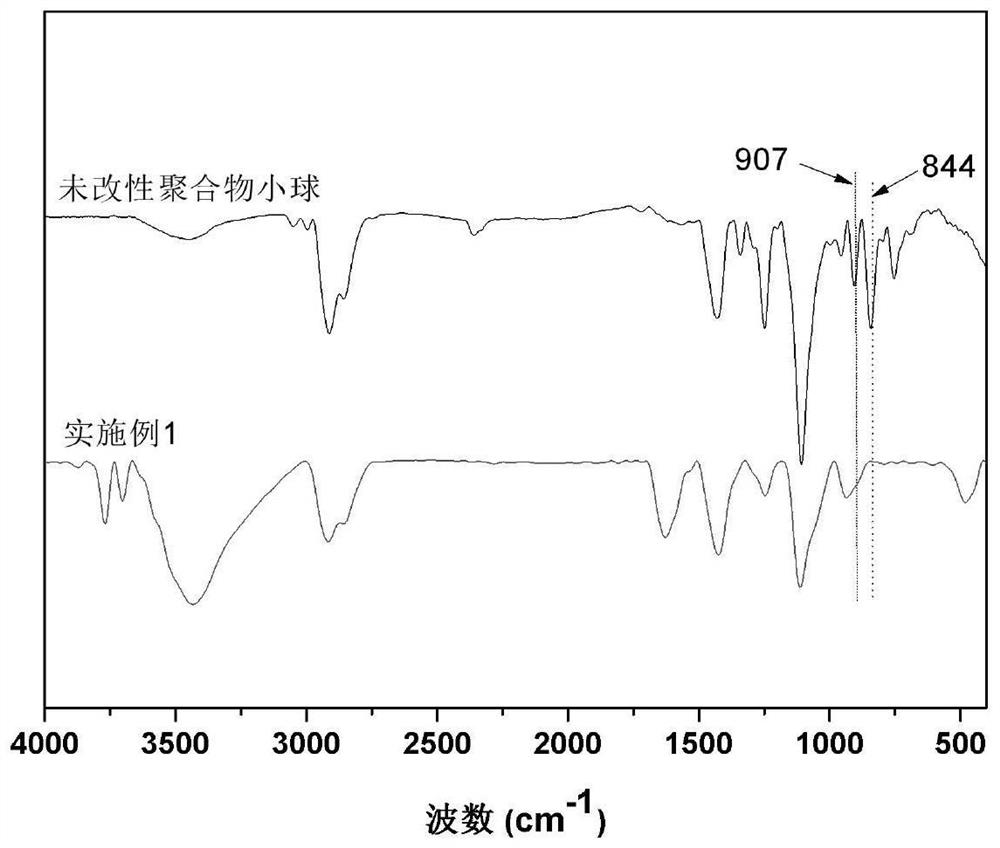

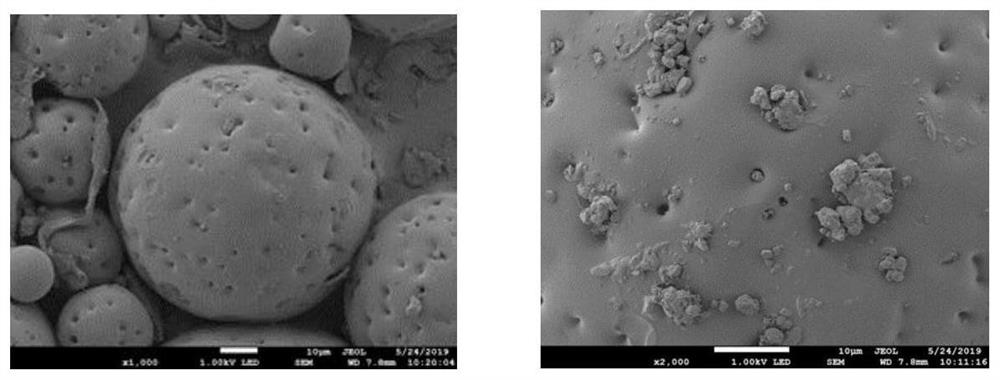

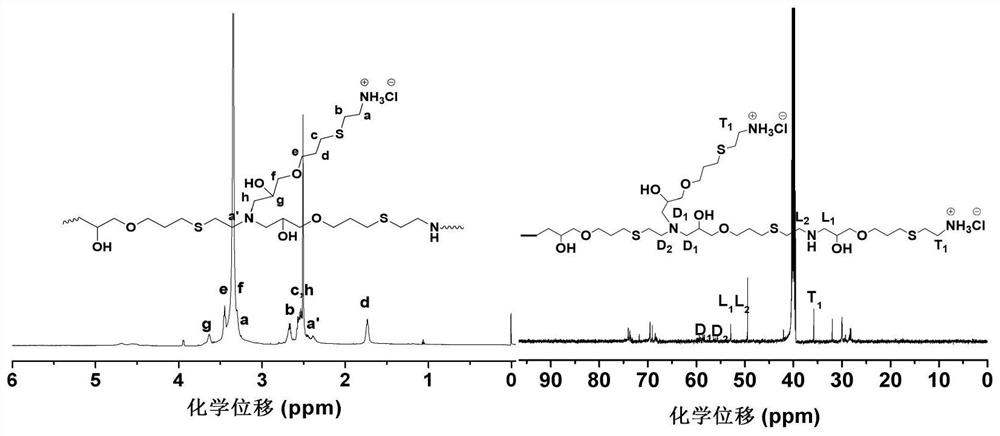

[0057] A kind of synthetic method of the polymer microsphere of quaternary ammonium salt type hyperbranched polysulfide modification, comprises the following steps:

[0058] S1: Under nitrogen protection conditions, add allyl glycidyl ether (313.5mg, 2.746mmol), cysteamine hydrochloride (312.5mg, 2.750mmol), benzoin dimethyl ether (27.8mg, 0.11mmol) and 2.027g of methanol were added to the rotor and sealed with a rubber stopper, then placed in an ice-water bath at 0°C, and irradiated with ultraviolet light with a wavelength of 365nm for continuous reaction for 10 hours. Precipitate the obtained product in a mixed solution of anhydrous ether and petroleum ether (volume ratio 3:2), and obtain an α-epoxy-ω-ammonium intermediate after drying;

[0059] S2: Add epoxy-based porous polymer microspheres (200mg), the α-epoxy-ω-ammonium-based intermediate (200.3mg) obtained in step S1, 1.53g methanol, a stirring magnet, and rubber Plug and seal, and stir and mix evenly with a magnetic s...

Embodiment 2

[0066] A kind of synthetic method of the polymer microsphere of quaternary ammonium salt type hyperbranched polysulfide modification, comprises the following steps:

[0067] S1: Under nitrogen protection conditions, add allyl glycidyl ether (792.9mg, 6.945mmol), cysteamine hydrochloride (790.5mg, 6.954mmol), 2-hydroxy-2- Methyl-1-phenyl-1-propanone (51.1mg, 0.30mmol) and 7.42g methanol were added to the rotor and sealed with a rubber stopper, then placed in an ice-water bath at 0°C, and irradiated with ultraviolet light with a wavelength of 365nm for continuous reaction 10 hours. Precipitate the obtained product in a mixed solution of anhydrous ether and petroleum ether (volume ratio 3:2), and obtain an α-epoxy-ω-ammonium intermediate after drying;

[0068] S2: Add epoxy-based porous polymer microspheres (7.2mg), the α-epoxy-ω-ammonium-based intermediate (720.6mg) obtained in the S1 step, 7.53g methyl alcohol, and a stirring magnet in a round-bottomed flask, and use The rubb...

Embodiment 3

[0074] A kind of synthetic method of the polymer microsphere of quaternary ammonium salt type hyperbranched polysulfide modification, comprises the following steps:

[0075] S1: Add allyl glycidyl ether (242.0mg, 2.125mmol), cysteamine hydrochloride (241.3mg, 2.123mmol), 2,4,6- Trimethylbenzoyldiphenylphosphine oxide (29.1mg, 0.09mmol) and 5.59g methanol were added to the rotor and sealed with a rubber stopper, then placed in an ice-water bath at 0°C, and irradiated with ultraviolet light with a wavelength of 365nm for continuous reaction 10 hours. Precipitate the obtained product in a mixed solution of anhydrous ether and petroleum ether (volume ratio 3:2), and obtain an α-epoxy-ω-ammonium intermediate after drying;

[0076] S2: Add epoxy-based porous polymer microspheres (40.0mg), the α-epoxy-ω-ammonium-based intermediate (200.6mg) obtained in the S1 step, 3.71g methanol, and a stirring magnet in a round-bottomed flask, and use The rubber stopper was sealed, and the mixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com