A mobile phone shell glue coating device

A shell coating and mobile phone technology, which is applied to devices and coatings for coating liquid on the surface, can solve the problems of inability to scrape the glued layer, overflow of glue, and high cost, and achieve uniform coating and overall structure. Simple, efficient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

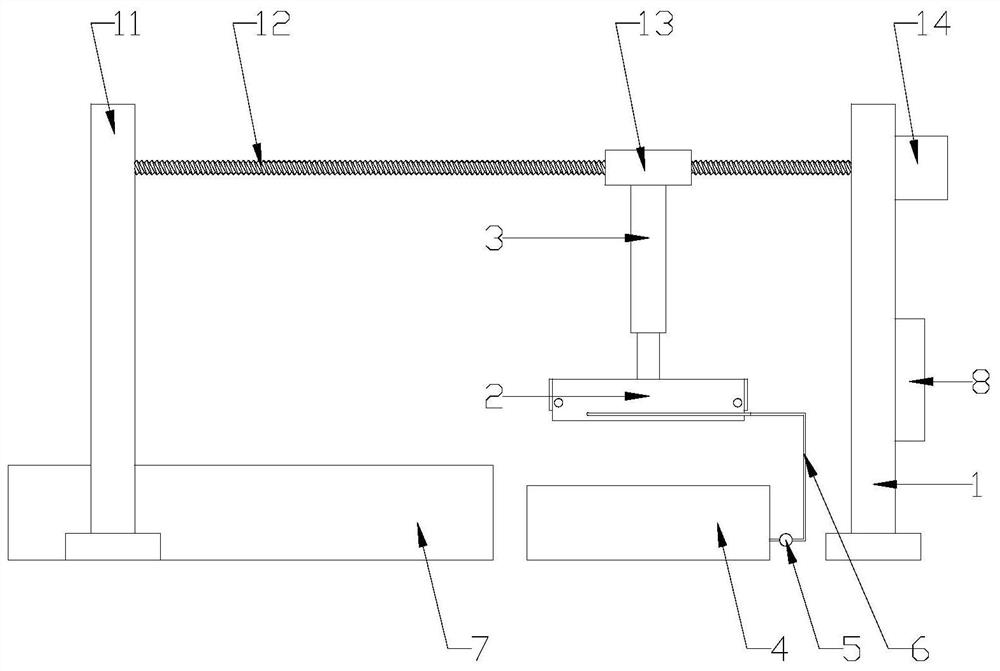

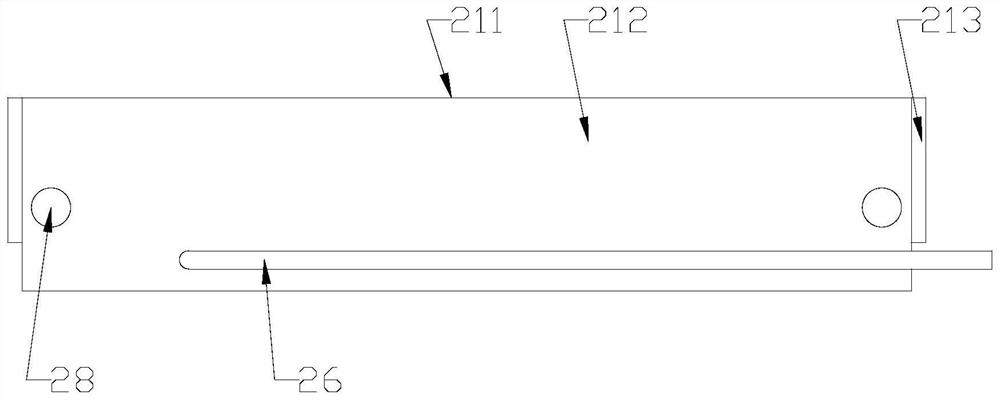

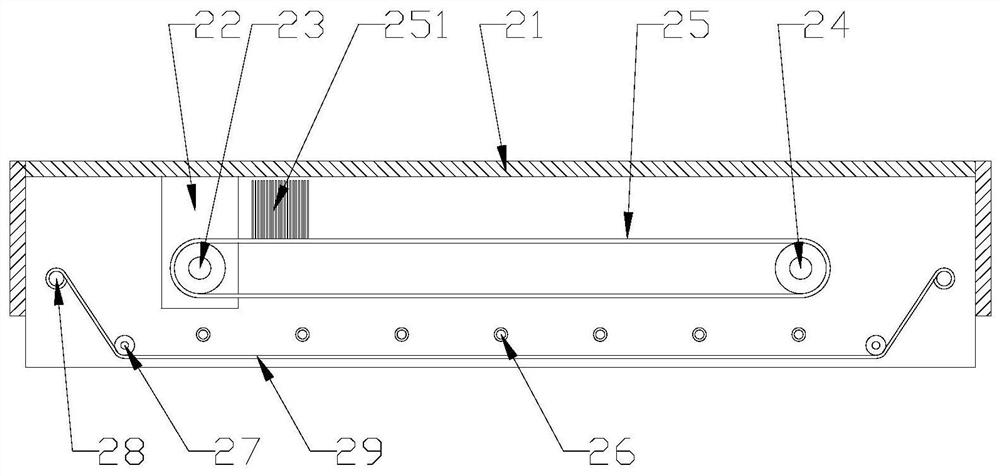

[0018] refer to Figure 1 to Figure 5 , a mobile phone case gluing device of the present invention, comprising a cylinder 3, a gluing head 2 fixed at the end of a telescopic rod of the cylinder 3, and a conveyor frame 1 that drives the cylinder 3 to move horizontally above the glue tank 4 and the conveyor belt 7, The gluing head 2 includes an outer casing 21, a driving wheel 23 and a driven wheel 24 fixed to the left and right ends of the outer casing 21, a first motor 22 that drives the driving wheel 23 to rotate, and is sleeved on the driving wheel 23 and the driven wheel 24. Outside the belt 25, the silk screen 29 fixed under the belt 25 and the shower head 26 between the belt 25 and the silk screen 29, the surface of the belt 25 is fixed with a brush 251, the liquid inlet of the shower head 26 Be connected with the liquid outlet of pump 5 by flexible pipe 6, the liquid inlet of described pump 5 is connected with the liquid outlet of glue tank 4 by flexible pipe 6, describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com