Efficient and compact vacuum cup necking machine

A thermal insulation cup and necking technology, which is applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of high manufacturing cost, cumbersome operation, and insufficient compactness, and achieve compact structure, convenient and quick operation, and reduce manufacturing cost and the effect of using cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

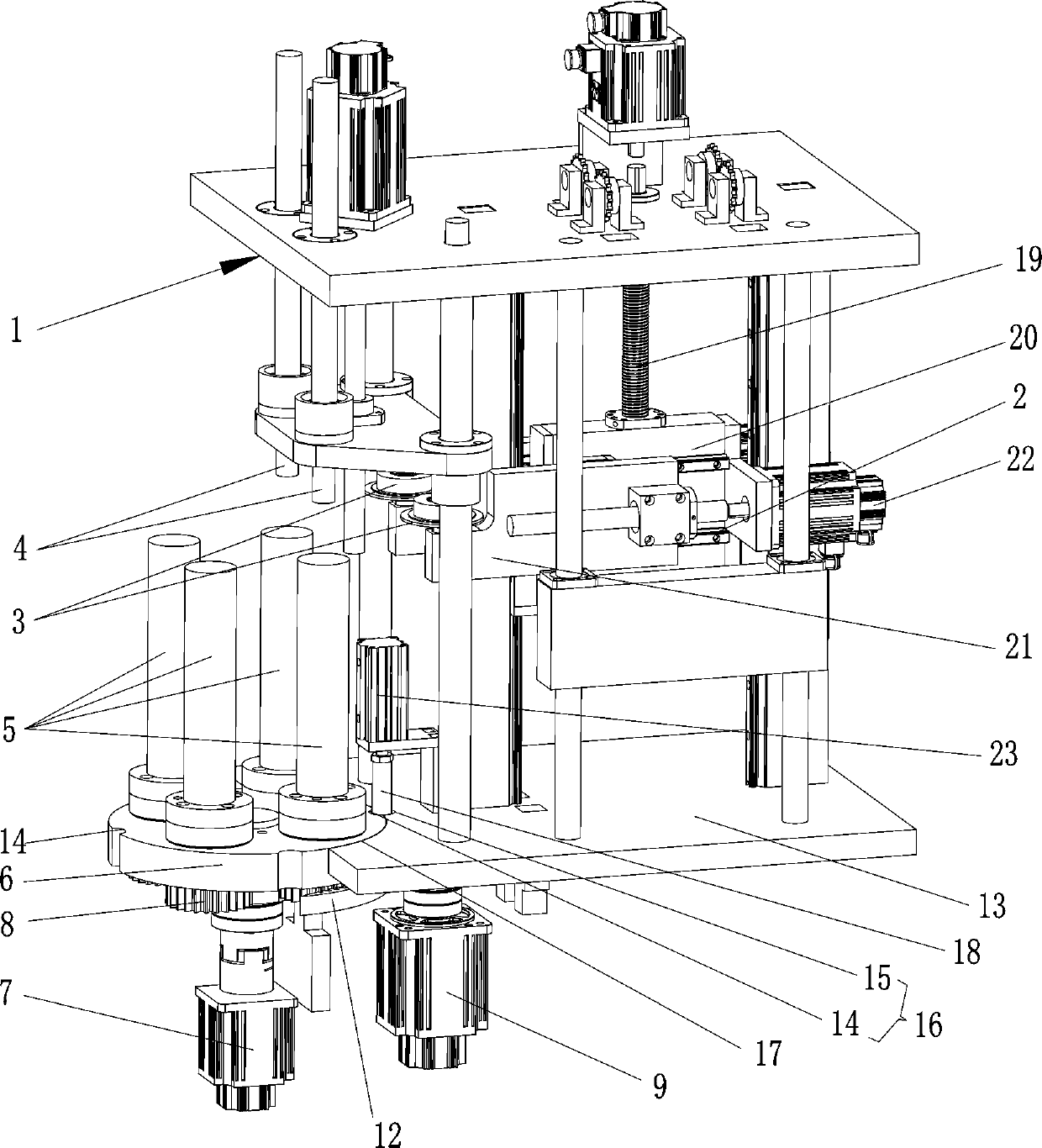

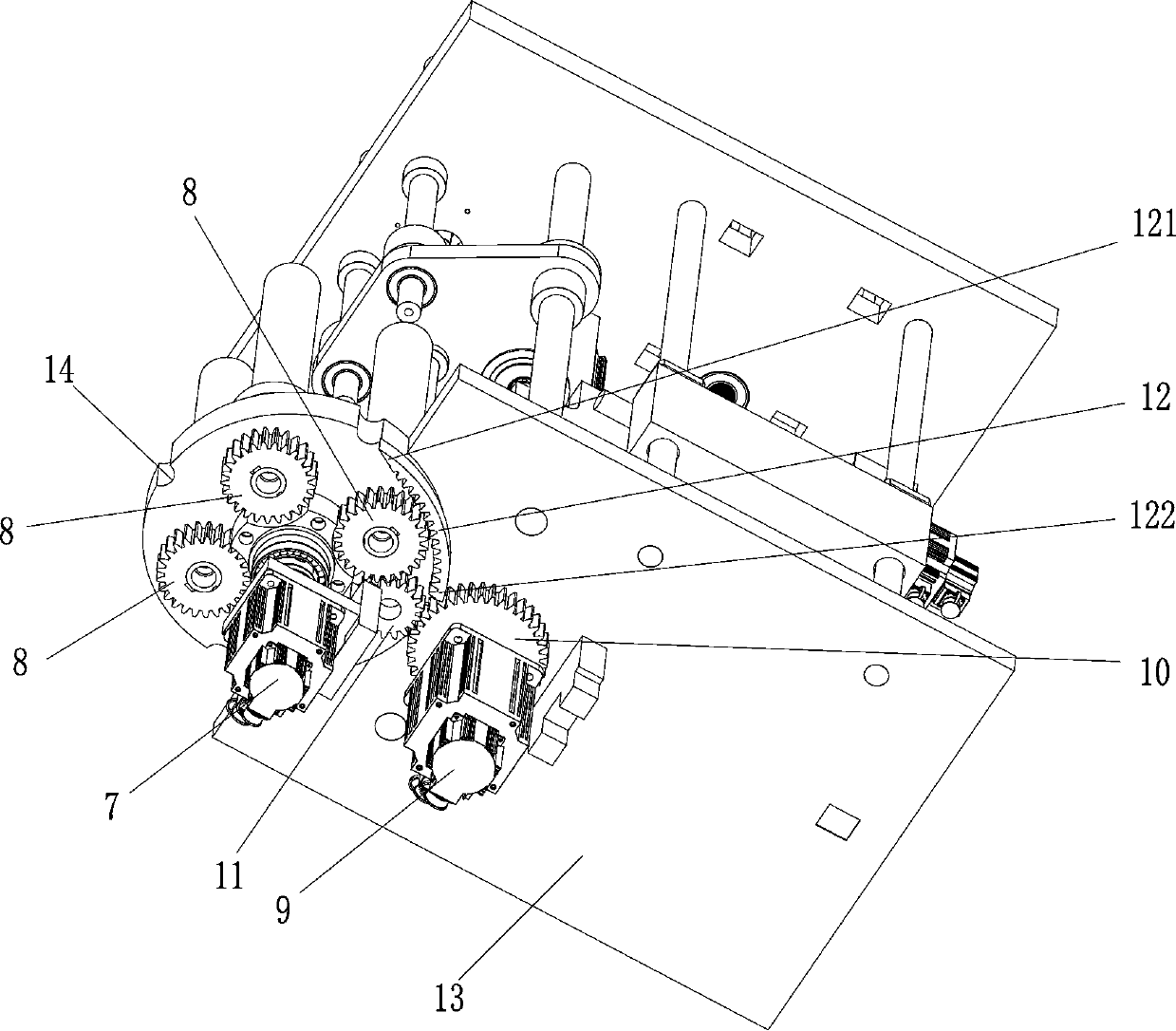

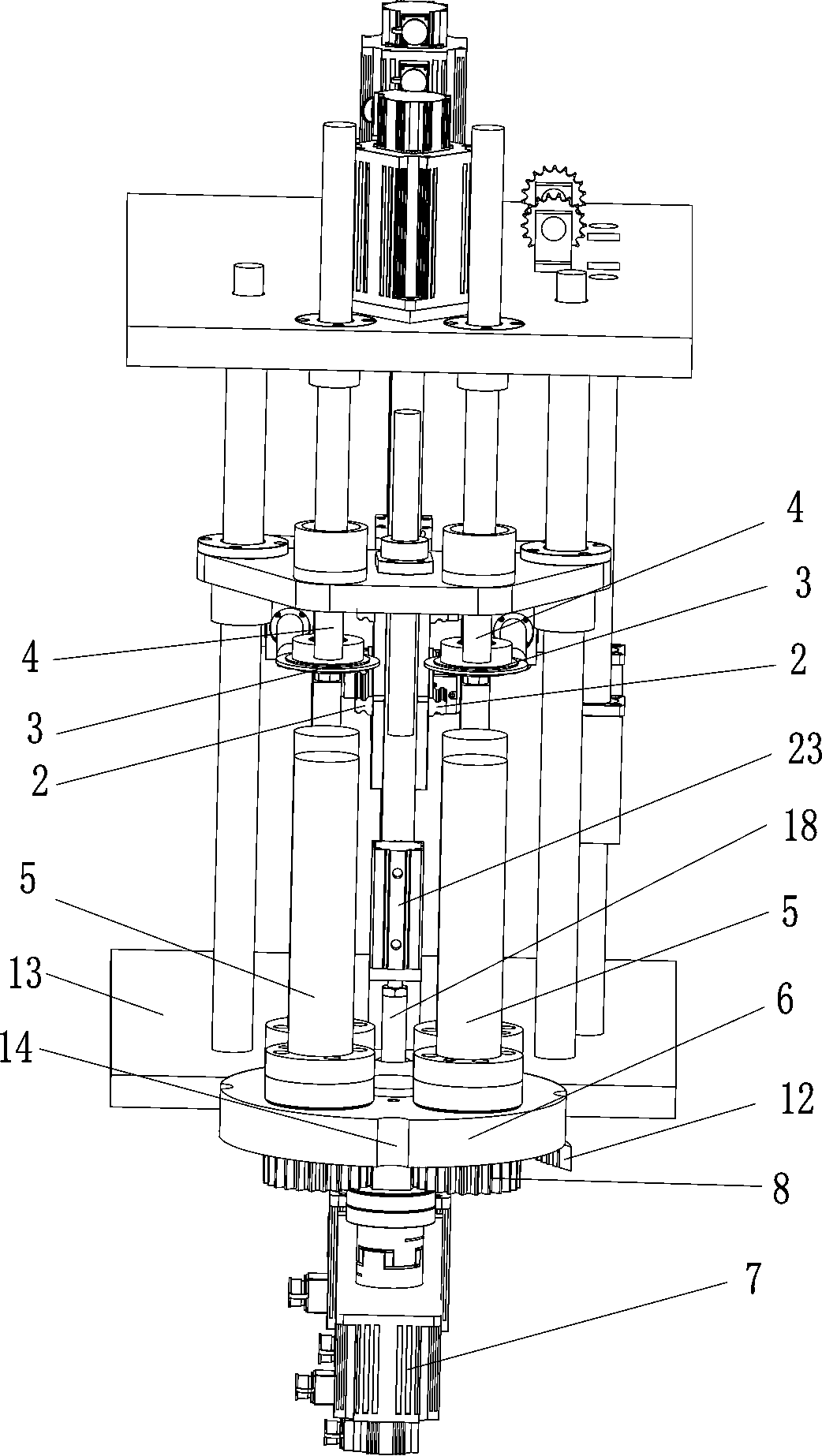

[0021] refer to Figure 1-4 As shown, a highly efficient and compact thermos cup necking machine includes a frame 1; a horizontal guide rail 2 arranged horizontally on the frame 1; a necking roller 3 slidingly connected to the lateral guide rail 2; a cup body The fixed frame 5 and the positioning part 4 that can move longitudinally and be used to position the top of the cup body, the cup body fixed frame 5 is provided with 4 and is mounted on a turntable 6 for common longitudinal rotation, the necking roller 3 and the positioning There are two components 4, the turntable 6 is driven to rotate by the first motor 7, the lower end of the cup holder 5 is respectively connected to the transmission gear 8, and the transmission gear 8 passes through the main motor 9 on one side of the turntable 6. Driven by the main gear 10 on the top, the main gear 10 drives two of the transmission gears 8 to rotate at the same time, and a transition gear 11 is meshed between the two transmission ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com