Side wall skin feeding assisting equipment

An equipment and skin technology, applied in the field of side wall skin feeding assist equipment, can solve the problems of high labor intensity of workers, affecting quality, skin torsion deformation, etc., to reduce the number of employees, facilitate welding operations, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

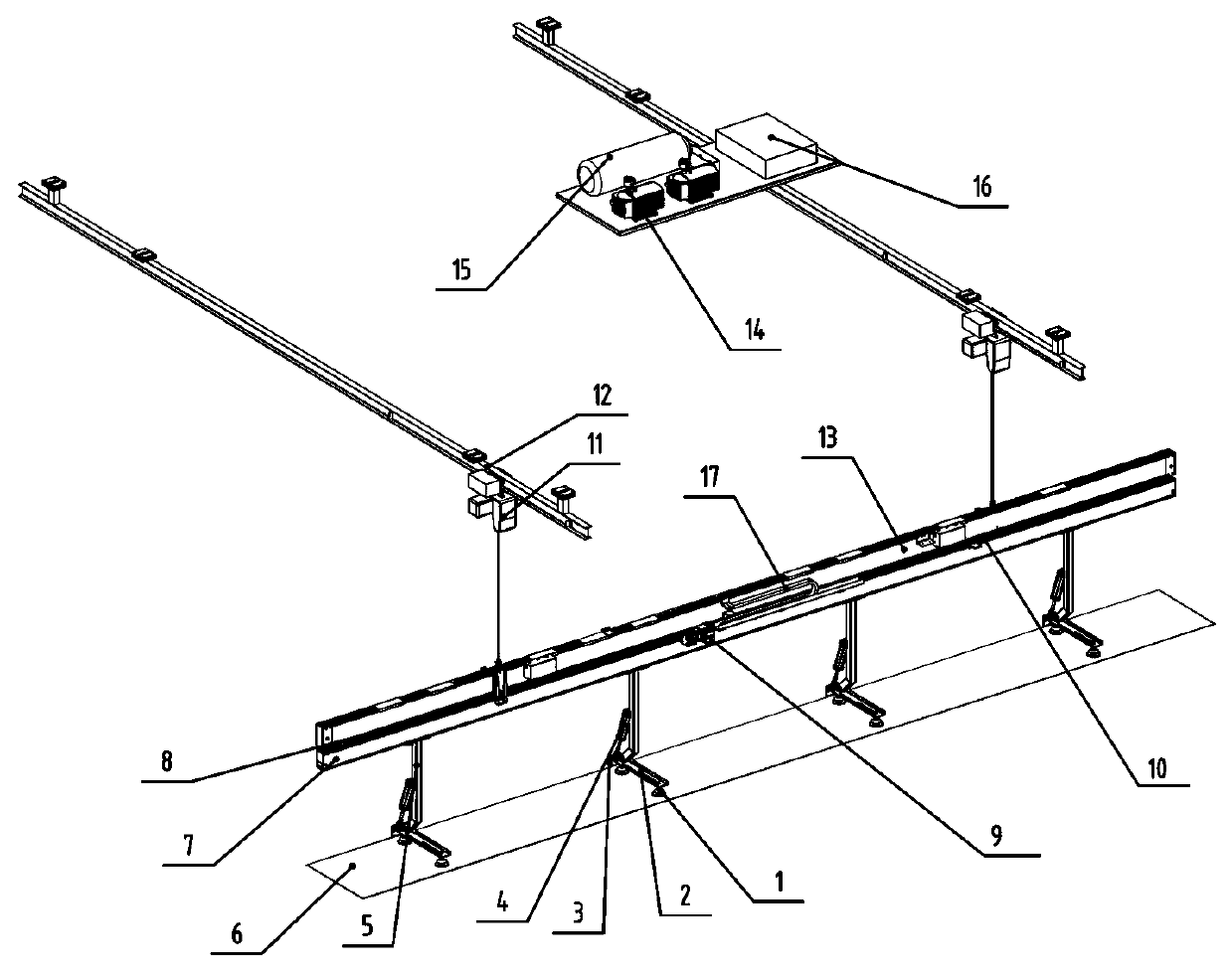

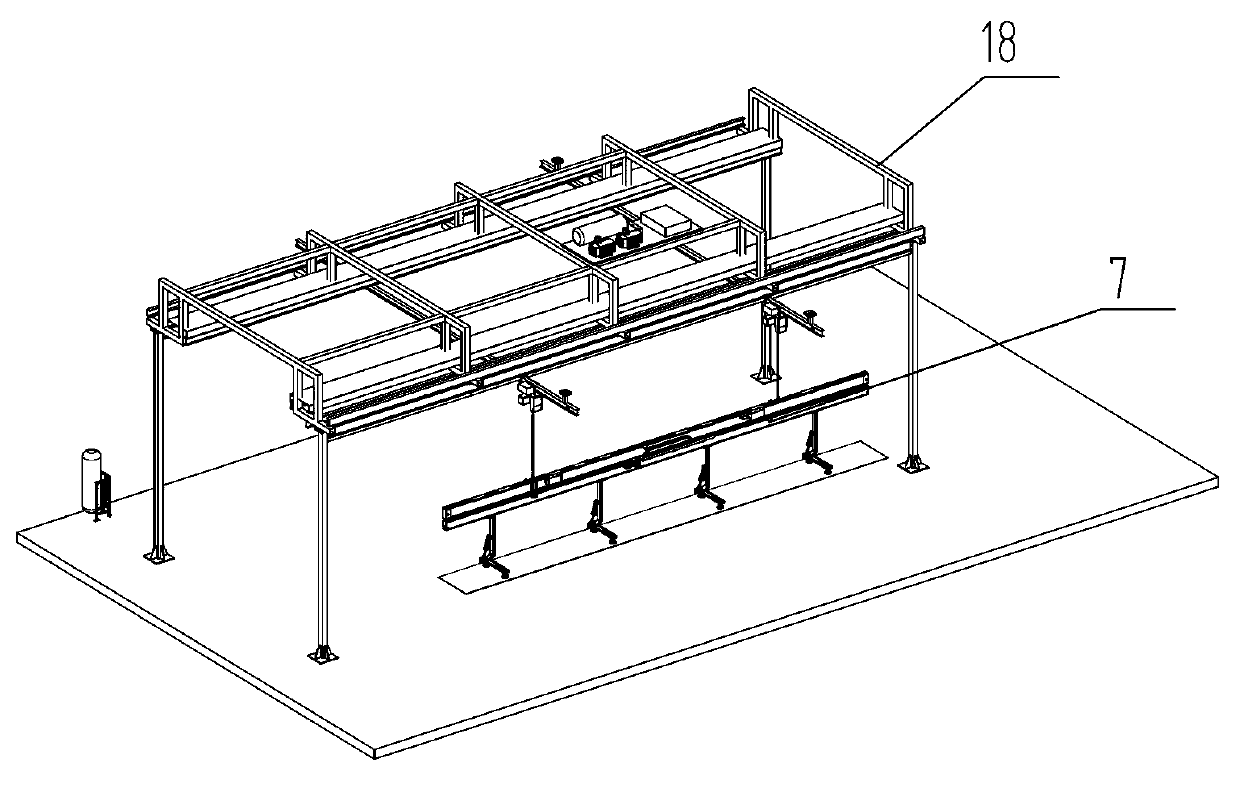

[0026] Such as Figure 1 ~ Figure 3 As shown in the figure, a side skin feeding and assisting device includes an electric hoist walking I-steel track 12, and an electric chain hoist 11 with a walking function is arranged on the electric hoist walking I-steel track 12. The bottom of the electric chain hoist 11 is connected with the boom walking track, and the boom 5 is arranged under the boom walking track. Two vacuum suction cups 1 are provided.

[0027] The electric hoist walking I-steel rail 12 has two arranged side by side, and the top of one of them is provided with a vacuum pump 14, and the vacuum pump 14 is connected with a vacuum tank 15 and vacuumized, and the vacuum tank 15 is connected with the vacuum chuck 1 through a trachea. Overturning cylinder 4, vacuum pump 14 and electric chain hoist 11 with walking function are all connected with electric control box 16.

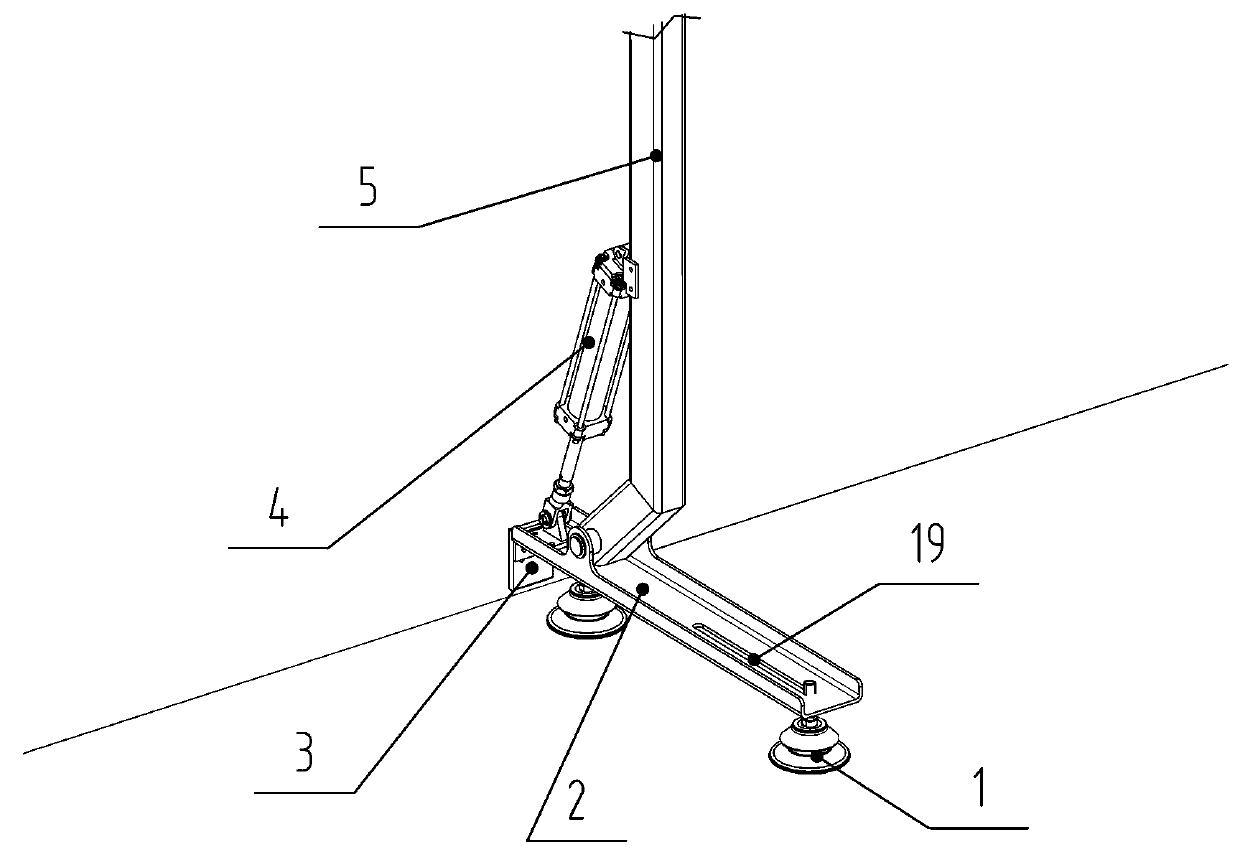

[0028] The vacuum suction cup 1 is mounted on the suction cup mounting base 2 through a threaded conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com