Robot end effector quick connecting and replacing device and connecting and replacing method

An end-effector and switching device technology, which is applied in the field of robot end-effector quick-changing devices, can solve the problems of time-consuming, labor-intensive, and difficult end-effectors, and achieves the effects of quick disassembly and assembly, good reliability, and large load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

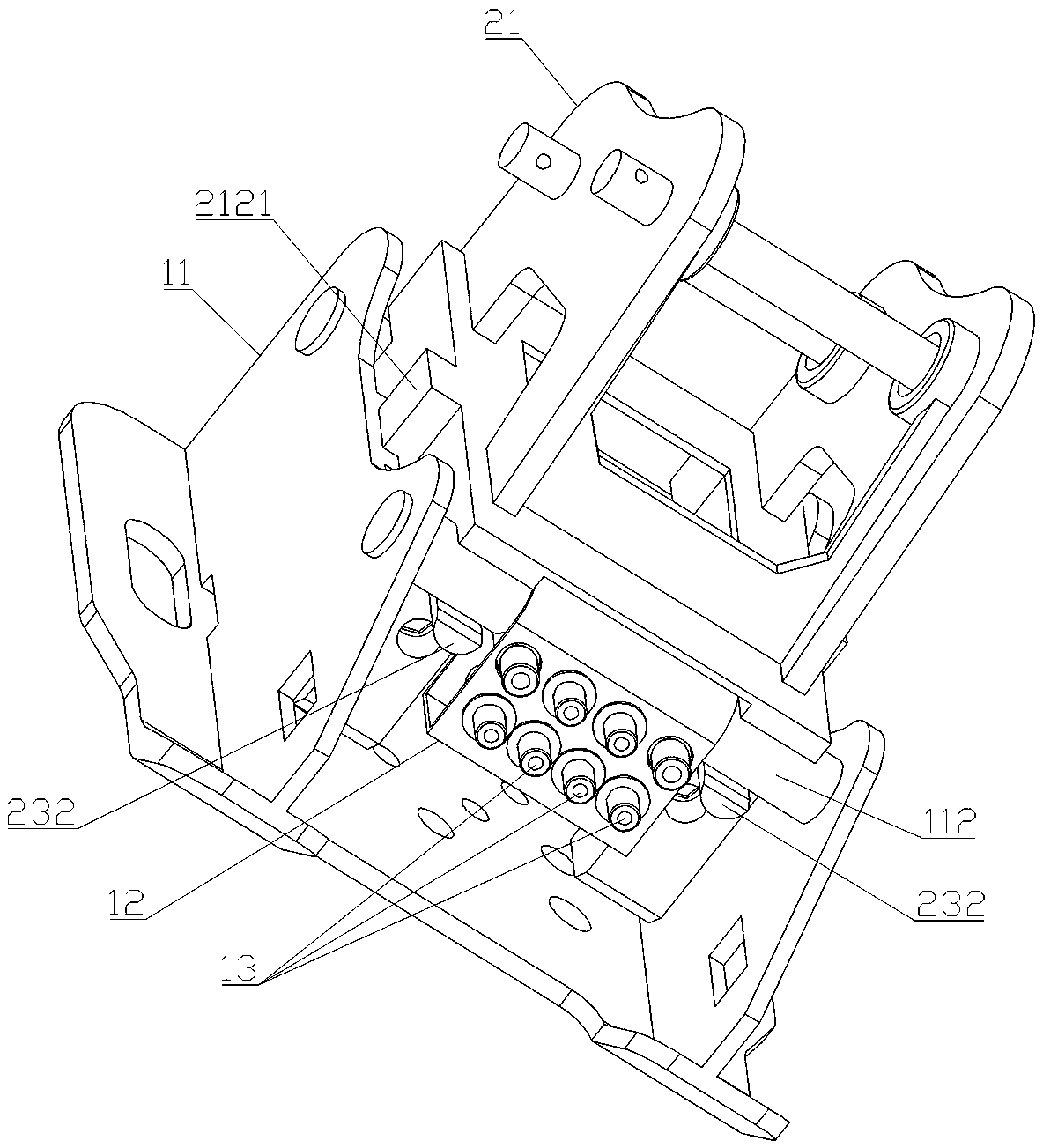

[0042] Such as Figure 1-7 As shown, the quick-change device for the robot end effector includes a first assembly and a second assembly.

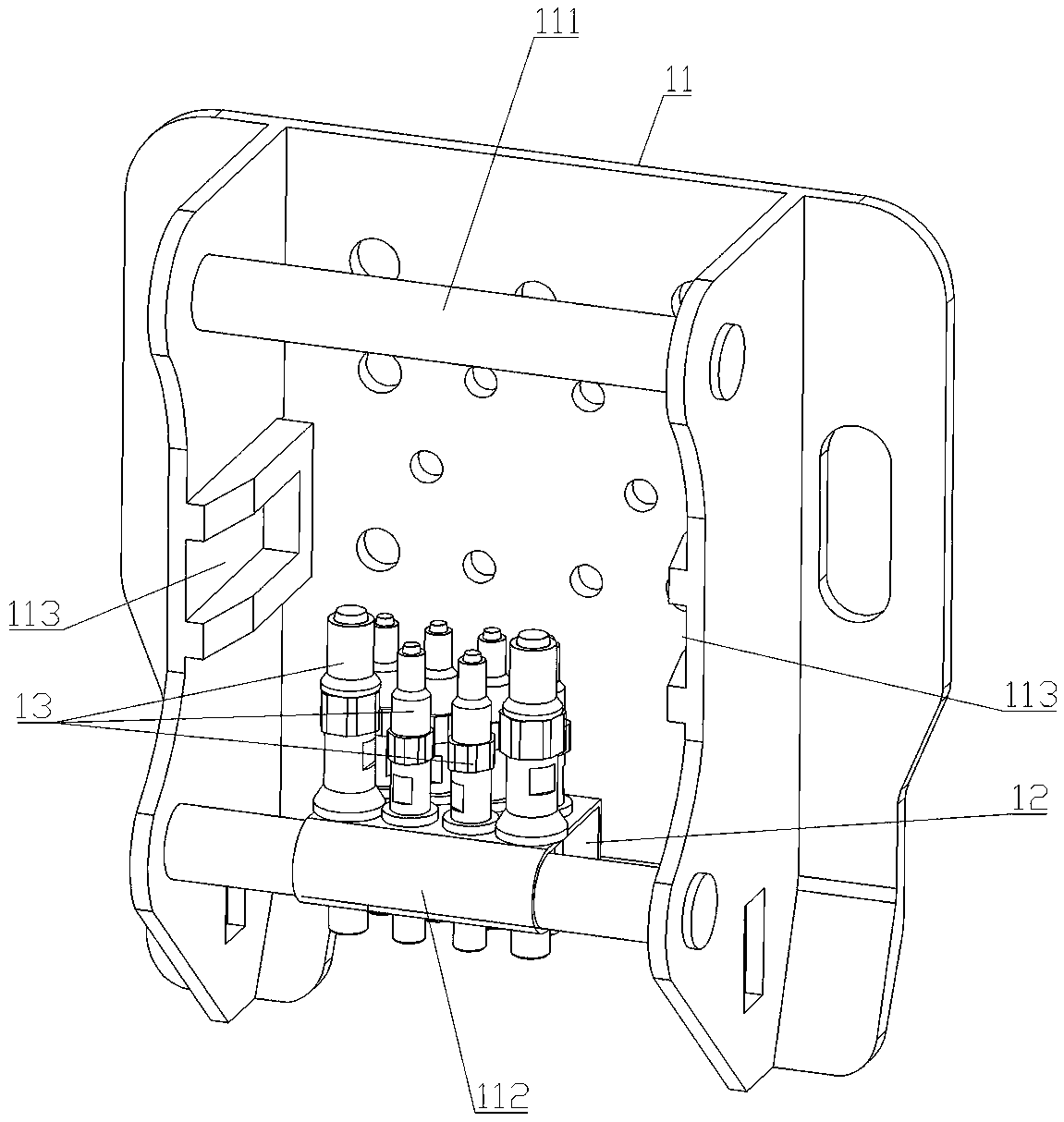

[0043] The first assembly includes a tool tray 11 , a male connector seat 12 and a male connector 13 .

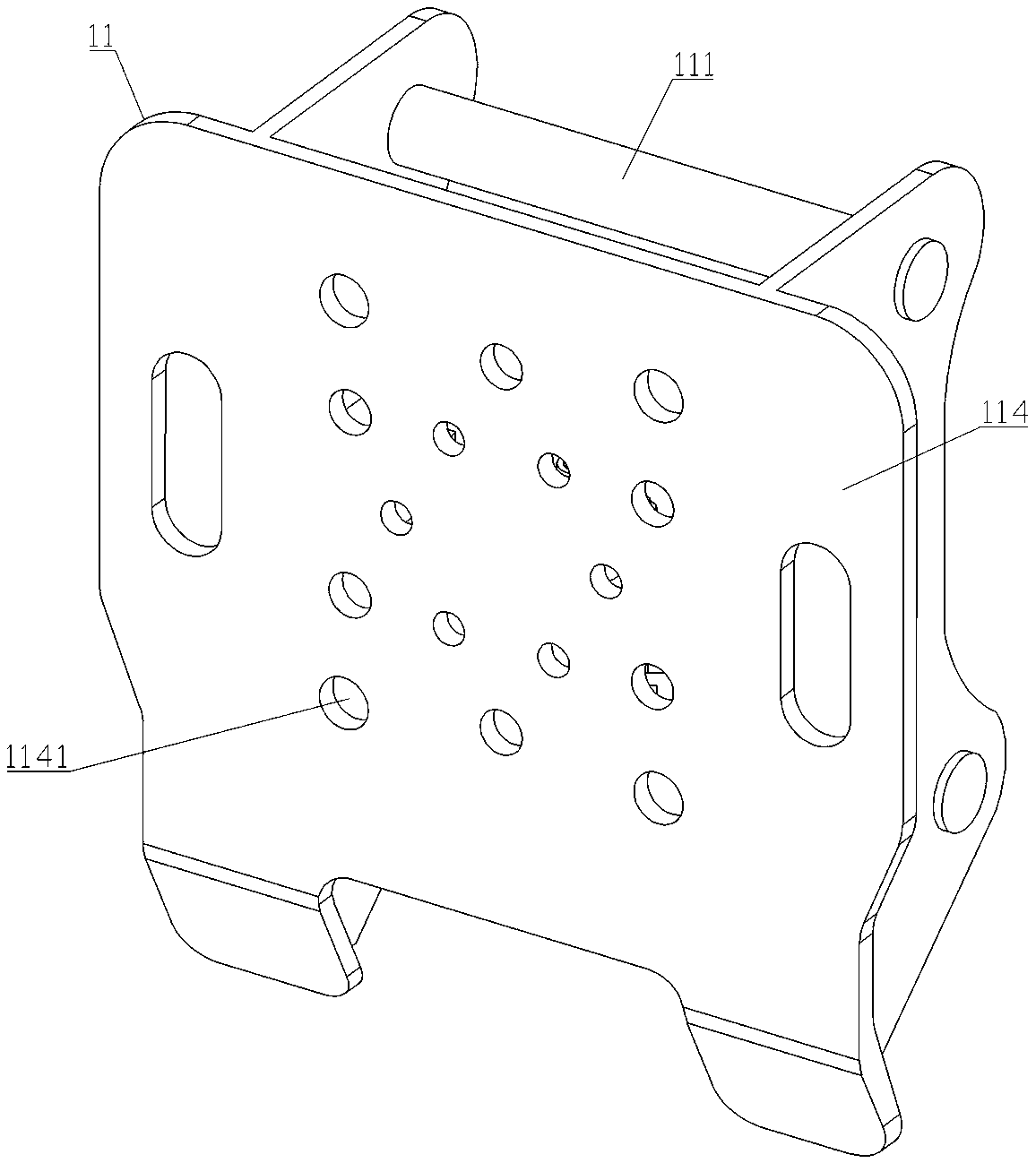

[0044] One side of the tool tray 11 is provided with an upper arm 111 , a lower arm 112 and an insertion part A113 in order from top to bottom, and the other side is provided with a tool connection surface 114 , and a tool installation hole 1141 is provided on the tool connection surface 114 .

[0045] The male connector seat 12 is fixedly connected to the tool tray 11 and located between the upper arm 111 and the lower arm 112 , and the male connector 13 is installed on the male connector seat 12 .

[0046] The second assembly includes a connection base 21 , a locking arm assembly A, a locking arm assembly B, a female connector 24 and a female connector seat 25 .

[0047]Two ends of the connection base 21 are respectively provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com