Material forming device

A material forming device and material technology, applied in the direction of metal processing, etc., can solve the problems of equipment cost impact, affecting work efficiency, slow conveyor belt transmission frequency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

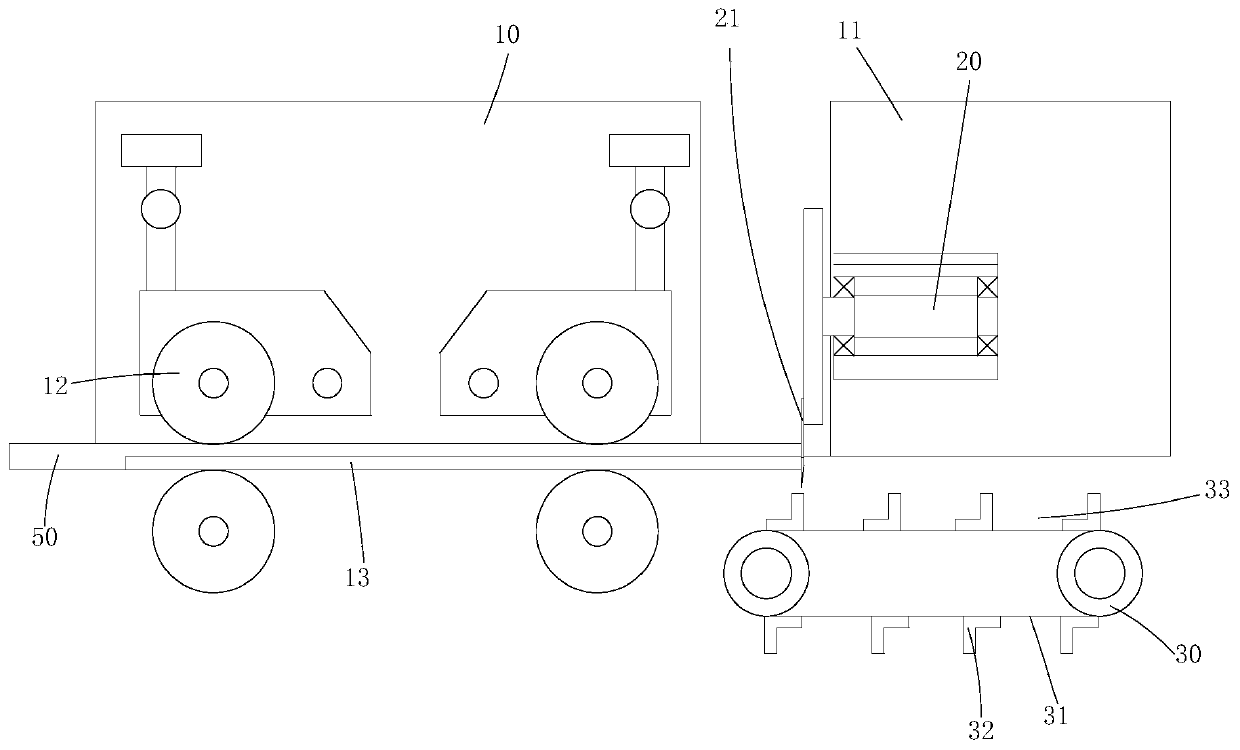

[0012] Example 1, see figure 1 Shown: a material forming device, including a body, a material strip conveying device, a material cutting device and a material block conveying device, the body is composed of a front frame 10 and a rear frame 11, and the material strip conveying device is arranged on the front frame 10 on, and there is a feeding motor and a feeding pinch wheel 12 on it, and the feeding motor is connected with the feeding pinch wheel 12 and drives it to rotate; on the front frame 10, there is a material bar guide groove 13 that is used in conjunction with the feeding pinch wheel 12, and the material bar The guide groove 13 can place the strip-shaped material 50 , which can move in the material strip guide groove 13 under the action of the feeding pinch wheel 12 . The material cutting device is located on the rear frame 11 and cooperates with the discharge port of the material bar guide groove. The structure of the material cutting device can be: comprising a rota...

Embodiment 2

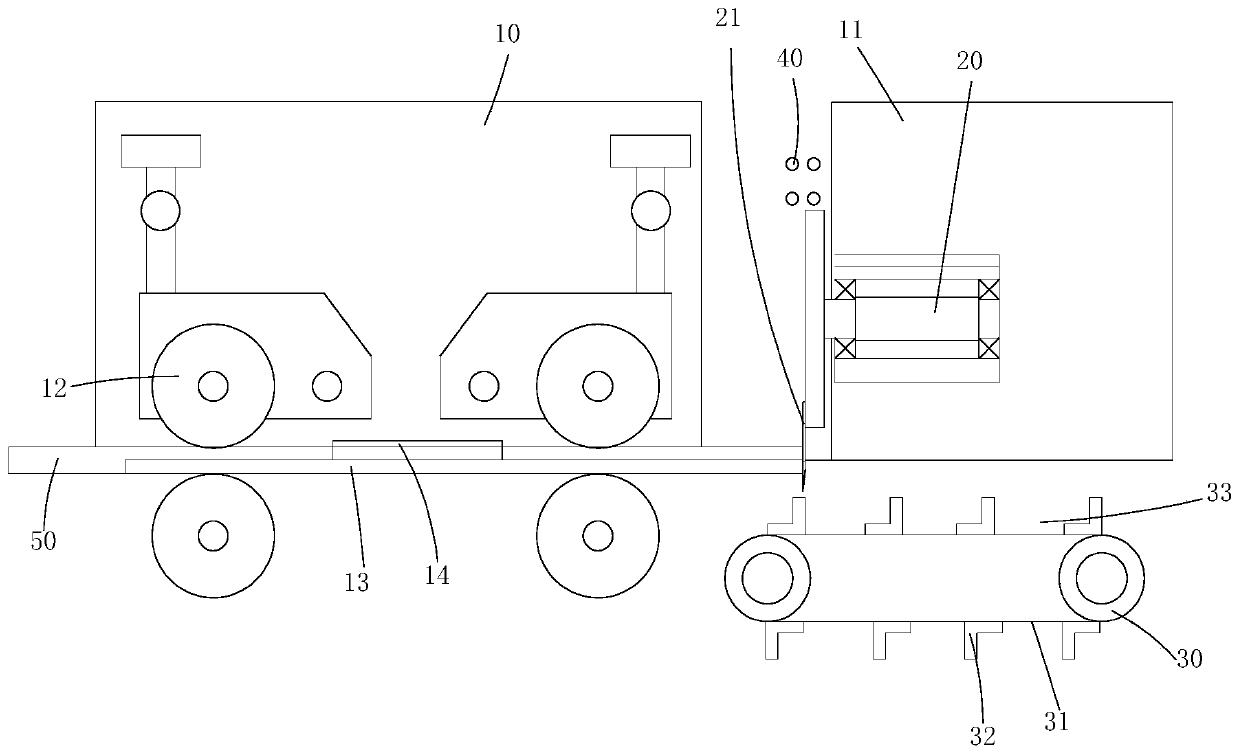

[0013] Example 2, see figure 2 As shown: the structure of embodiment 2 is roughly the same as that of embodiment 1, the difference is that: the material cutting device has an electromagnetic induction heater 40, and the electromagnetic induction heater 40 has a section for the cutting tool 21 to pass through and cut its magnetic field ; When the cutting tool 21 passes through this section, it will cut the magnetic field at this position, thereby generating an alternating current, allowing the cutting tool 21 to generate heat, thereby melting the material particles sticking to it, so that the cut material automatically falls off. There is a pressing plate 14 on the material bar guide groove 13, and the material bar 14 can prevent the material bar from falling out of the material bar guide groove 13, and plays a better positioning role.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com