Automatic silk changing 3D printer

A 3D printer and printer technology, applied in the field of 3D printing, can solve the problems of easy mixing of mixed-color printing materials, manual intervention, etc., and achieve efficient, fast, fast and residue-free replacement, and improve efficiency and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

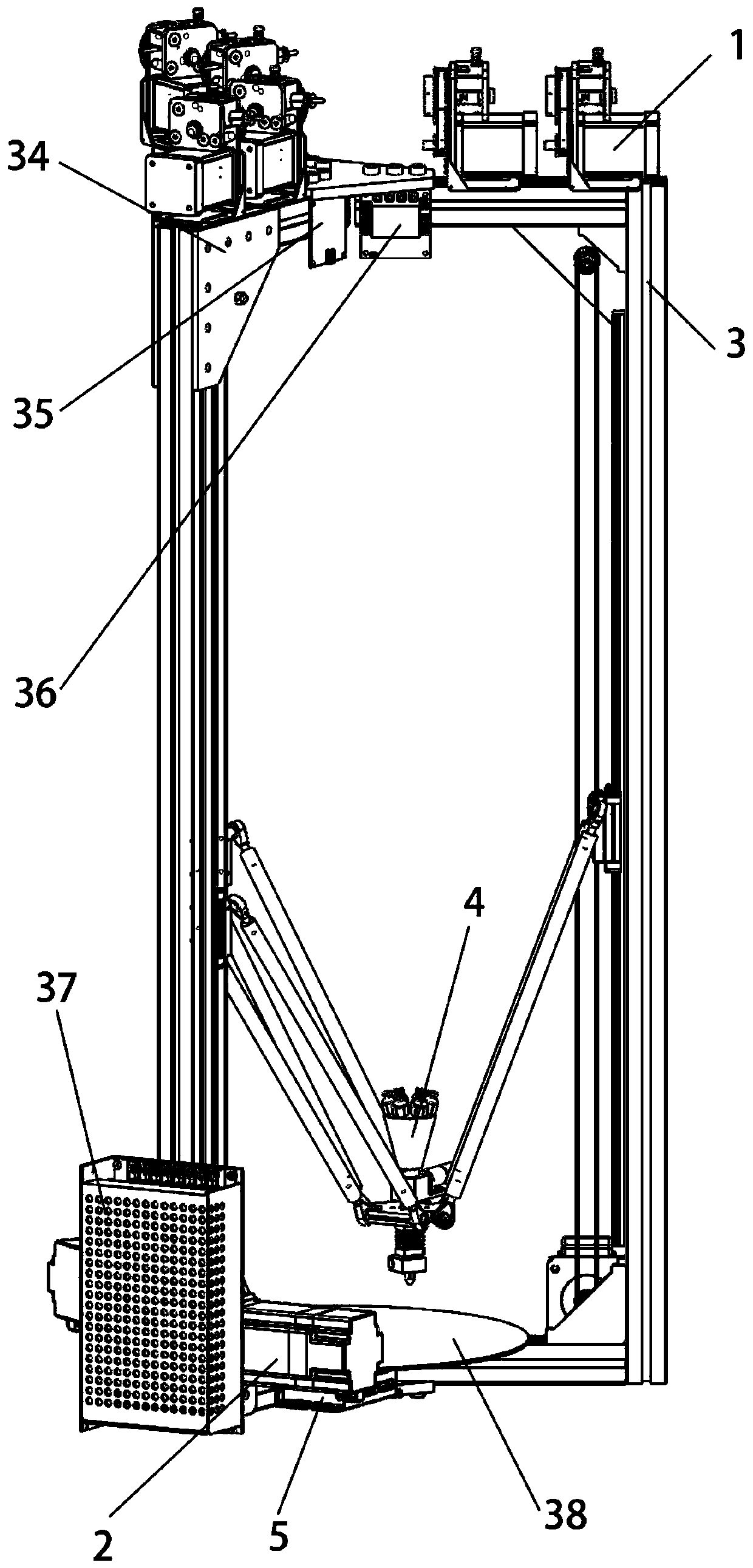

[0020] refer to Figure 1 ~ Figure 4 , a 3D printer with automatic wire changing, including a printer frame and a print head drive system 2 installed on the printer frame, six extruders 1, a six-in-one automatic wire-cutting print head 4, a control module and a power supply module, the The print head driving system 2 is installed on the printer frame 3, and the six extruders 1 are arranged on the top of the printer frame 3, and the six-in-one automatic shredding print head 4 is arranged on the printer effector, and the printer effector can slide up and down installed on the printer frame, the heated bed for placing printed products is set under the six-in-one automatic shredding print head, the power supply module is set on the side of the printer frame 3, and the control module is set on the upper part of the printer frame 3;

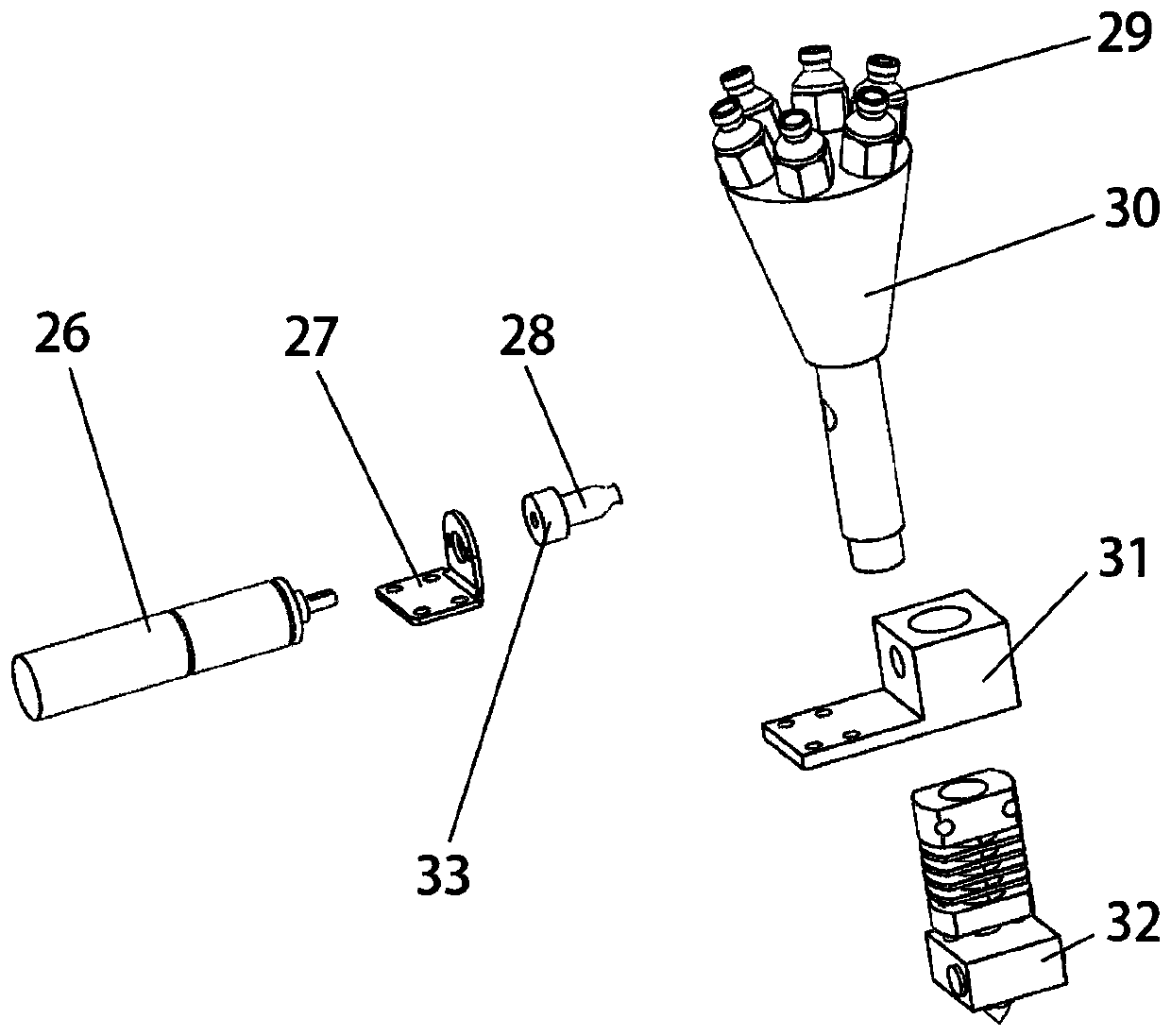

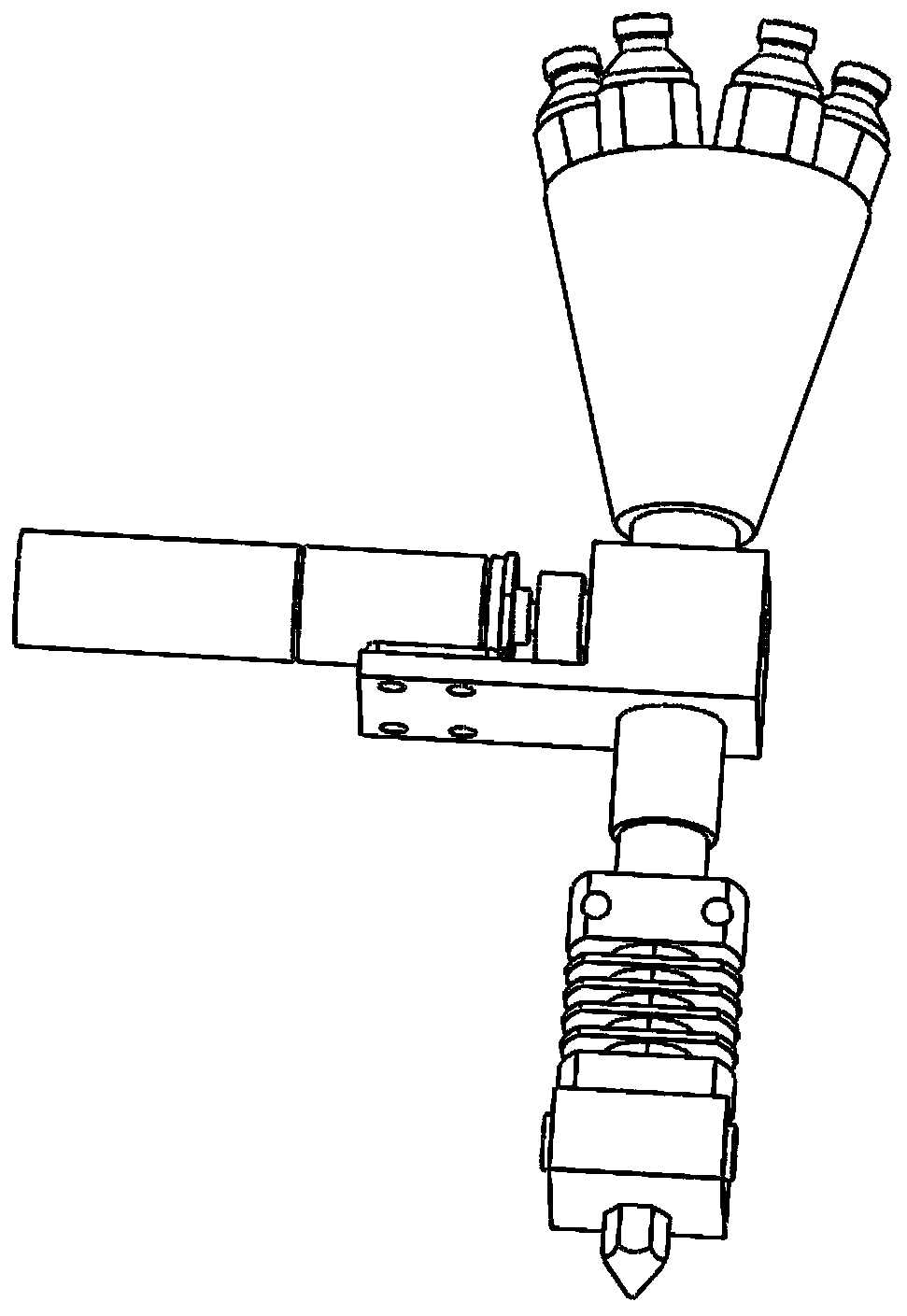

[0021] The six-in-one automatic wire-cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com