An internal installation structure of a vehicle charger and the vehicle charger

An on-board charger and installation structure technology, applied in electric vehicle charging technology, charging stations, vehicle parts, etc., can solve the problems of long installation time, low work efficiency, and circuit board time-consuming, etc. The effect of heat dissipation, improving installation efficiency and reducing the number of uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]In order to make the invention, the creation characteristics, the purpose and efficacy are readily understood, and in connection with the specific embodiments, the invention is further illustrated.

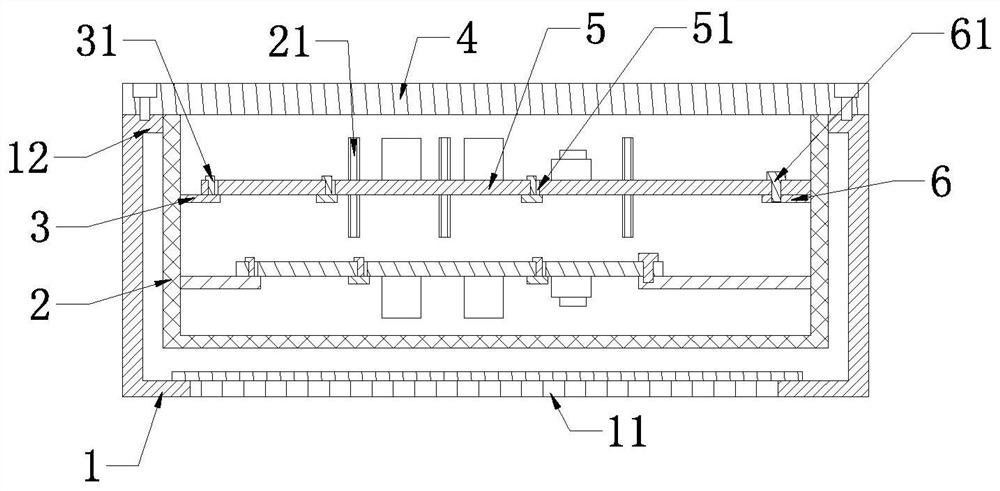

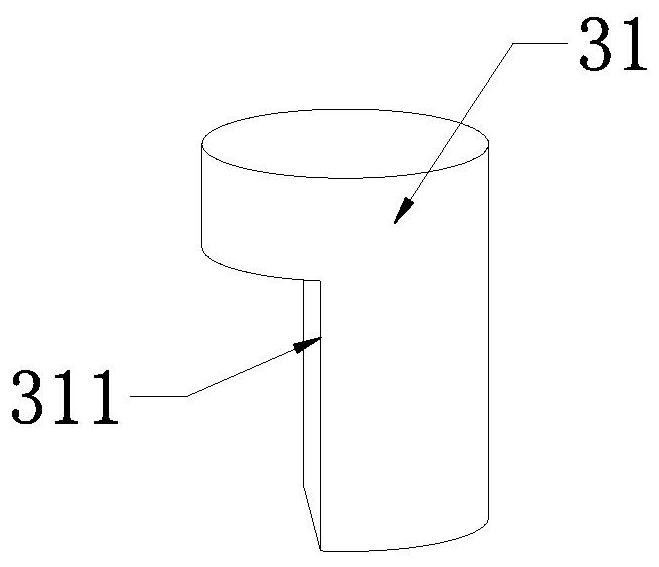

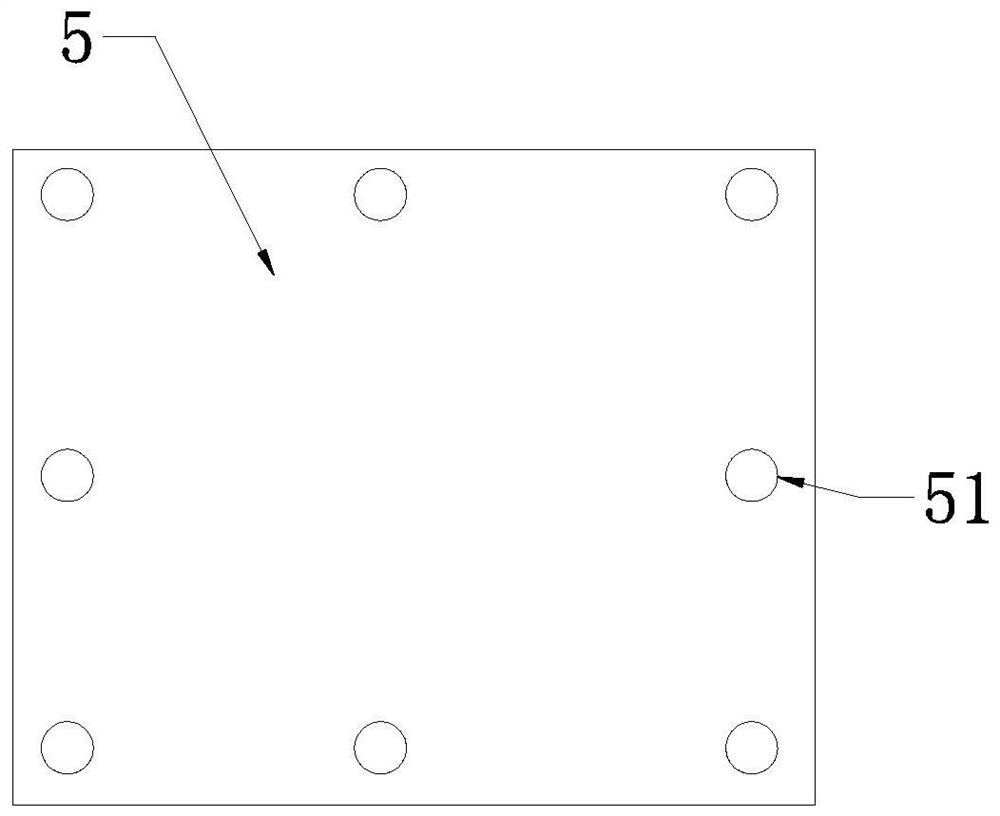

[0021]SeeFigure 1 - Figure 3The invention provides a technical solution: an internal mounting structure of a vehicle charger, including a casing 1, a casing 1 inside a web frame 2, and the structure of the mesh frame 2 facilitates air flow, thereby facilitating heat dissipation of the casing 1. The first connecting plate 3 in which the three adjacent sidewalls in the inside of the frame 2 is fixedly extended inwardly extended, and the second connecting plate 6, the first connecting plate 3, and the first connection plate 3, and the first The number and position of the dicing plate 6 is provided as needed, and the upper end of the first connection plate 3 fixes the card cassette 31, and the network frame 2 is provided with a circuit board 5 and the circuit board 5 is provided in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com