Platinum alloy crucible for drawing glass fibers and manufacturing method of platinum alloy crucible

A technology of glass fiber and platinum alloy, which is applied in the direction of glass manufacturing equipment and manufacturing tools, can solve the problems of not being able to obtain similar technology from open channels, not being able to melt glass batch materials, and not finding a similar technology, so as to shorten the test cycle , reduce test cost and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

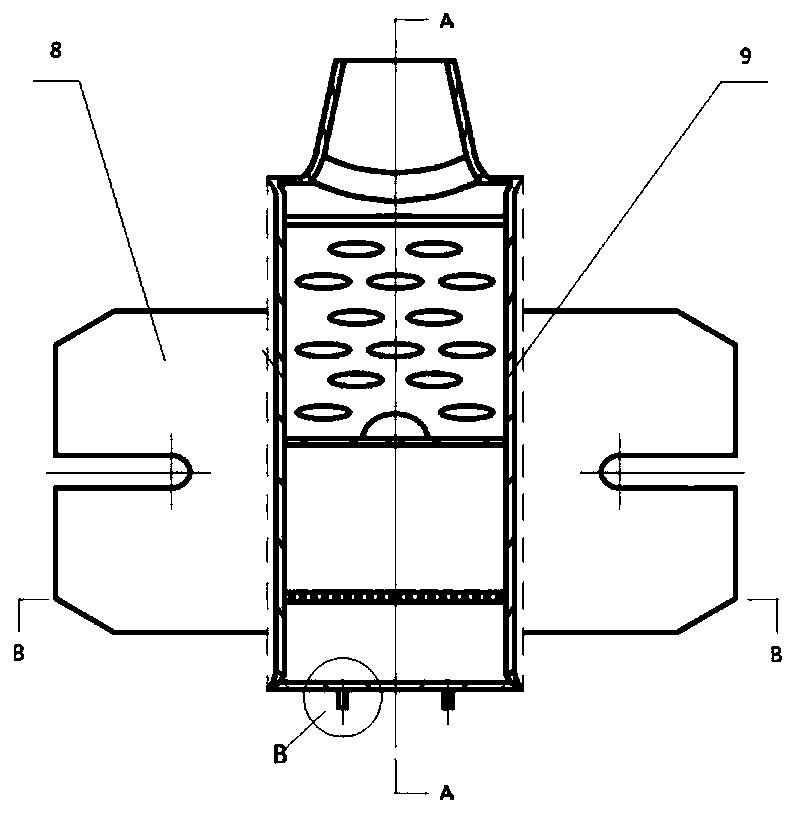

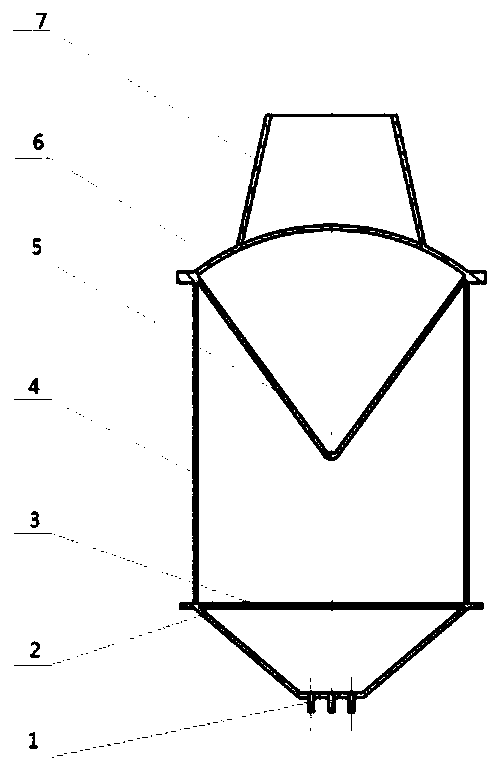

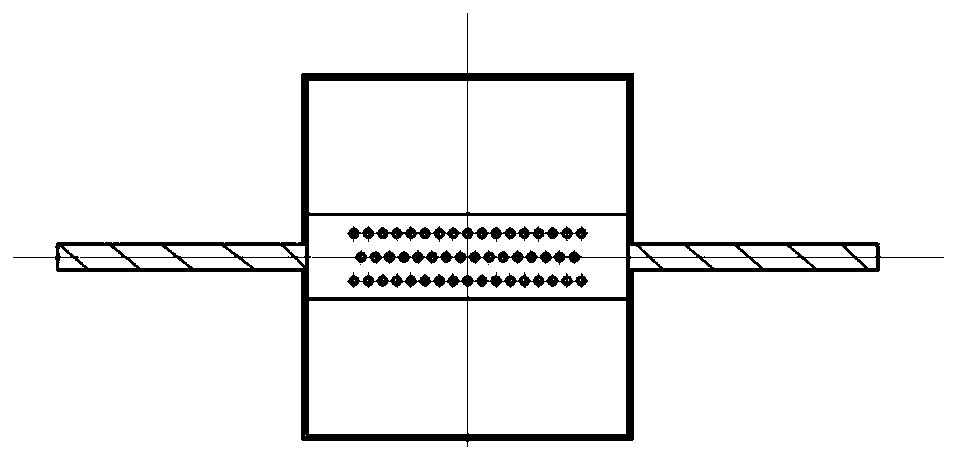

[0051] This embodiment is a kind of capacity is 1000cm 3 Platinum alloy crucible for low hole number glass batch drawing, including leak nozzle 1, leak plate 2, filter screen 3, crucible shell 4, heating plate 5, top cover 6, feeding tube 7, connecting electrode 8 and baffle plate 9 ; Wherein: the heating plate 5 is located in the crucible shell, and is located below the top cover. The top cover 6 is placed on the upper end surface of the crucible shell, and the connecting edge of the top cover is fixedly connected with the flange on the heating plate. Feeding pipe 7 is fixed on the through hole in the geometric center of the top cover. A filter screen 3 is fixed at the inner lower end of the crucible shell. The bushing 2 is located at the lower end outside the crucible shell; bushing side baffles are welded on both sides of the bushing. Two plate-shaped connecting electrodes 8 are symmetrically welded on the outer surface of the crucible shell. A leak nozzle 1 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com