Cobalt-manganese polymetallic oxide ore and seabed polymetallic sulfide combined metallization recovery method

A technology of polymetallic oxide ore and polymetallic sulfide, applied in the field of non-ferrous metal metallurgy, can solve the problems of high degree of oxidation, difficult to break alloy, heavy pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

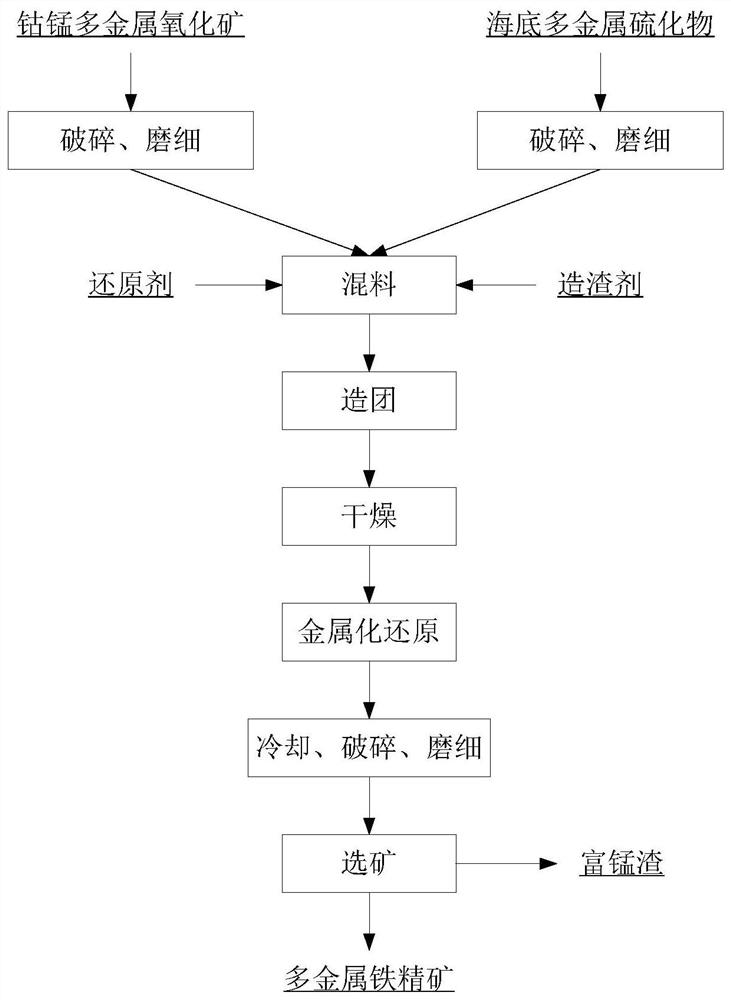

[0048] Such as figure 1 As shown, a cobalt-manganese polymetallic oxide ore and seabed polymetallic sulfide combined metallization recovery method may include the following steps:

[0049] Step 1. Cobalt-manganese polymetallic oxide ore containing 1.24% nickel, 0.23% cobalt, 0.82% copper, 6.3% iron, and 26.04% manganese and seabed polymetallic sulfidation containing 1.84% copper, 43.73% iron, and 48.40% sulfur Crushing and grinding the material until the particle size is more than 80% and less than 0.074mm, then drying the cobalt manganese polymetallic oxide ore to a moisture content of 15%, crushing and drying the seabed polymetallic sulfide to a moisture content of 10%, thereby obtaining cobalt manganese polymetallic oxide ore powder ore and seabed polymetallic sulphide fines.

[0050] Step 2, mixing the cobalt-manganese polymetallic oxide ore powder and the seabed polymetallic sulfide powder ore in a mass ratio of 5:1, and then adding 5% anthracite (as a reducing agent) an...

Embodiment 2

[0055] Such as figure 1 As shown, a cobalt-manganese polymetallic oxide ore and seabed polymetallic sulfide combined metallization recovery method may include the following steps:

[0056] Step 1. Sulfurize the cobalt-manganese polymetallic oxide ore containing 0.43% nickel, 0.6% cobalt, 0.058% copper, 15.26% iron, and 19.61% manganese and the seabed polymetallic sulfidation containing 6.37% copper, 39.40% iron, and 37.95% sulfur Crushing and grinding until the particle size is more than 70% and less than 0.074mm, then drying the cobalt-manganese polymetallic oxide ore to a moisture content of 15%, and crushing and drying the seabed polymetallic sulfide to a moisture content of 10%, thereby obtaining cobalt-manganese polymetallic oxide ore powder ore and seabed polymetallic sulphide fines.

[0057] Step 2, mixing the cobalt-manganese polymetallic oxide ore powder and the seabed polymetallic sulfide powder ore in a mass ratio of 7:1, and then adding 7% anthracite (as a reducin...

Embodiment 3

[0062] Such as figure 1 As shown, a cobalt-manganese polymetallic oxide ore and seabed polymetallic sulfide combined metallization recovery method may include the following steps:

[0063] Step 1. Cobalt-manganese polymetallic oxide ore containing 1.35% nickel, 0.17% cobalt, 0.92% copper, 5.8% iron, and 24.52% manganese and seabed polymetallic sulfidation containing 7.77% copper, 33.58% iron, and 40.25% sulfur Crushing and grinding until the particle size is more than 90% and less than 0.074mm, then drying the cobalt-manganese polymetallic oxide ore to a moisture content of 16%, and crushing and drying the seabed polymetallic sulfide to a moisture content of 12%, thereby obtaining cobalt-manganese polymetallic oxide ore powder ore and seabed polymetallic sulphide fines.

[0064] Step 2, mixing the cobalt-manganese polymetallic oxide ore powder and the seabed polymetallic sulfide powder ore in a mass ratio of 8:1, and then adding 4% anthracite (as a reducing agent) and 5% quar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com