Large-span steel box girder side span folding device and method

A steel box girder, large-span technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of uneven stress, difficult movement and damage of steel box girder, save time, facilitate the closing of side spans, Simple and reasonable operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

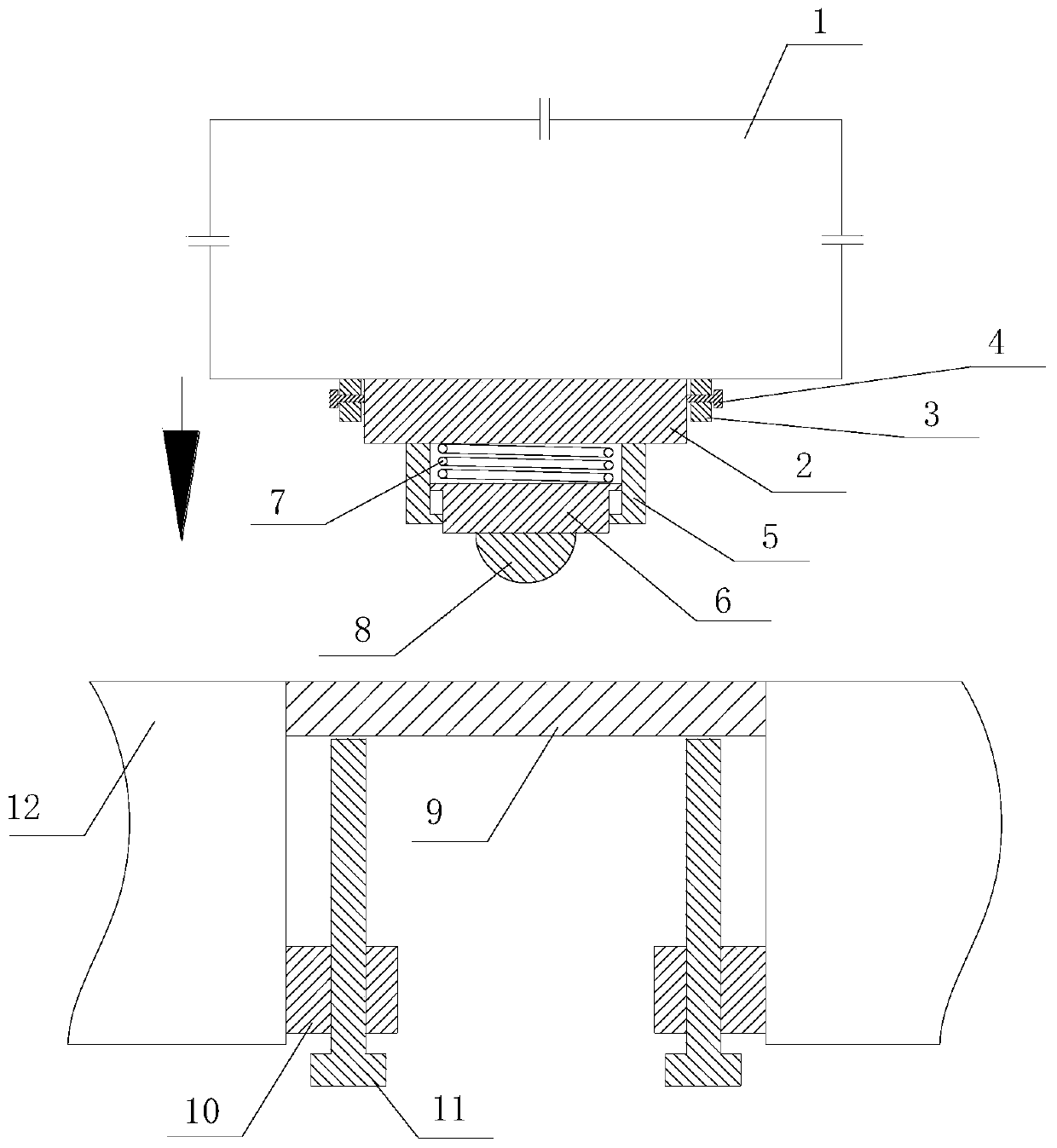

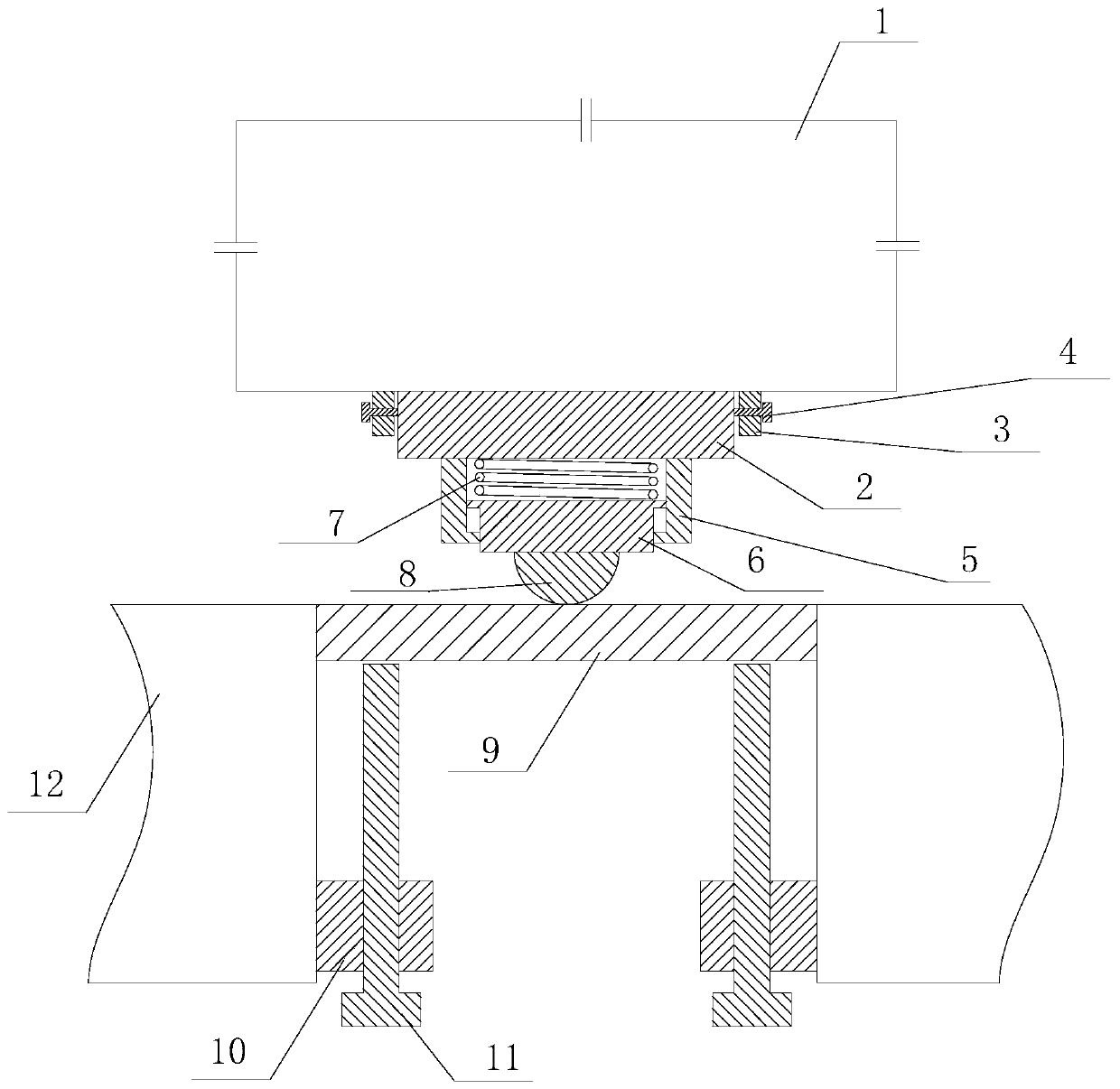

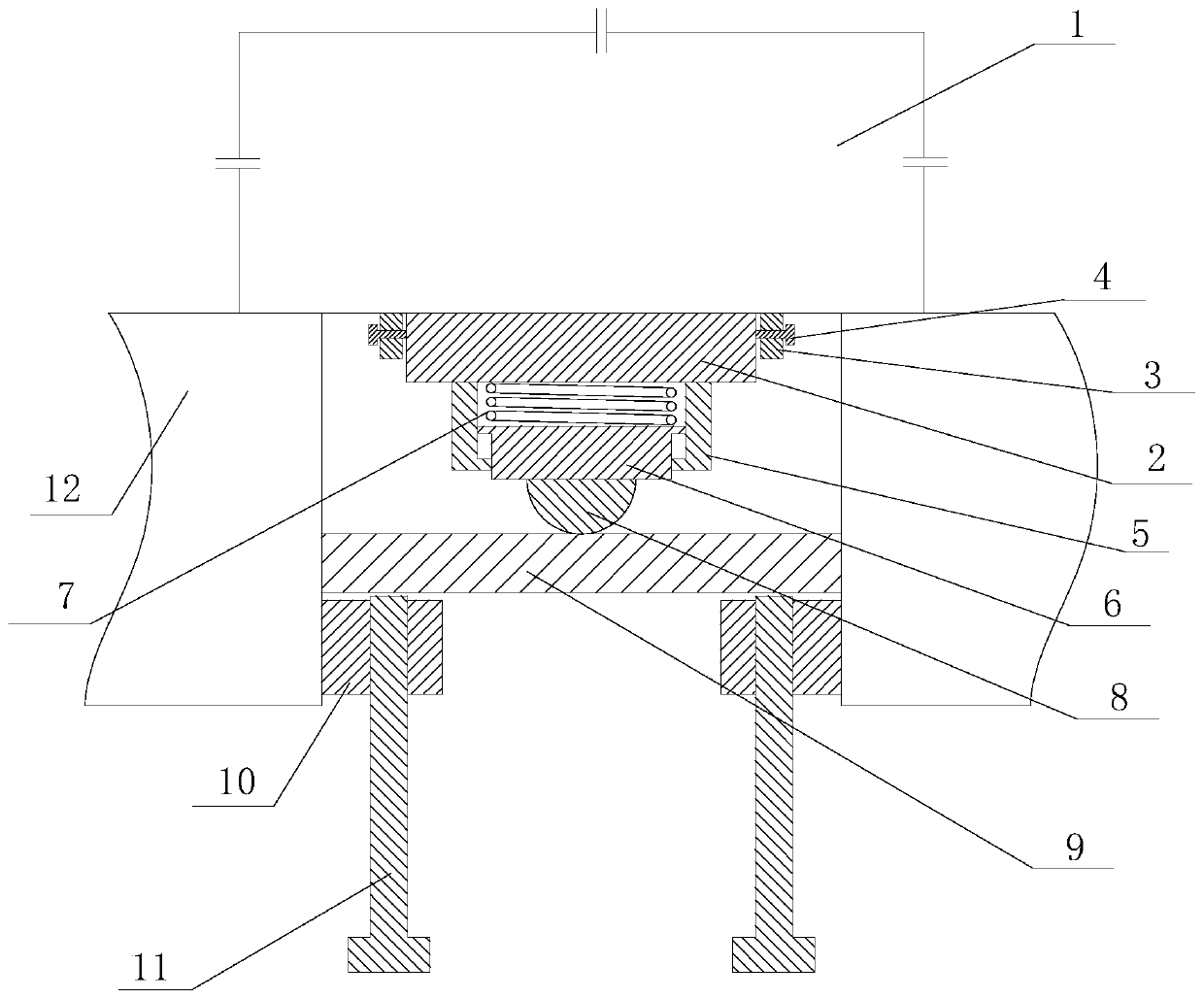

[0031] The large-span steel box girder side span closing device provided by the present invention includes: a steel box girder 1 and a bottom girder 12, the bottom of the steel box girder 1 is provided with an upper adjustment member, and the bottom girder 12 is provided with an adjustment device adapted to the upper adjustment member. The base; the height of the adjustment base is greater than or equal to the height of the upper adjustment part; the adjustment base can move up and down along the bottom beam 12 under the pushing action of the upper adjustment part.

[0032] see figure 1 , in this embodiment, the structure of the steel box girder 1 is rectangular, and the upper adjustment member includes a connecting member, a telescopic member and a rolling member arranged sequentially from top to bottom, and an opening is provided on the bottom beam 12, and an opening that can move up and down is arranged in the opening. Adjust the base.

[0033] The connector includes a fix...

Embodiment 2

[0037] The closing method of the large-span steel box girder side span closing device provided by the present invention comprises the following steps:

[0038] 1) Adjust the base so that the top end is flush with the surface of the bottom beam 12; when the steel box girder 1 is hoisted to a corresponding position above the bottom beam 12, the steel box girder 1 falls, and the buffer of the expansion part Under the action, the impact force of the steel box girder 1 is reduced during the falling process, and the rolling parts slowly contact the upper surface of the adjustment base and make point contact with the upper surface of the adjustment base, reducing the impact of the steel box girder 1 on the bottom beam under the double action force, reduce damage;

[0039] 2) Move the steel box girder 1 through the rolling parts, and precisely position it so that it is aligned with the adjacent steel box girder;

[0040] 3) Adjust the adjusting base to make it move downward, so the adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com