Copper-aluminum integrated current collector electrode, laminated battery and preparation process

A current collector and copper-aluminum technology, which is applied in the fields of copper-aluminum integrated current collector electrode, laminated battery and preparation process, can solve the problems of reducing the volume energy density of the battery, increasing the complexity of the process, and uneven current distribution, and achieving high quality Mitigation, reducing the risk of thermal runaway, the effect of increasing the volumetric energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

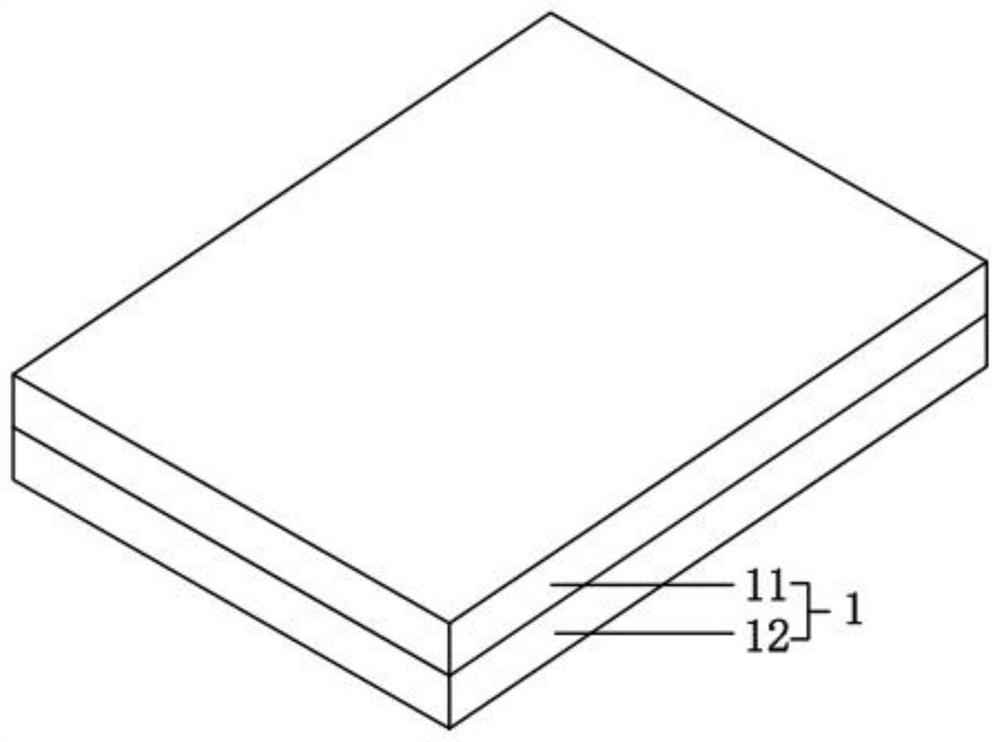

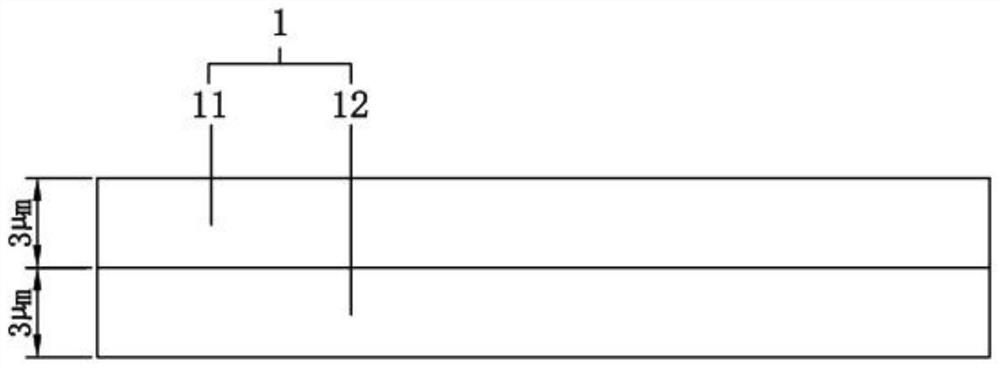

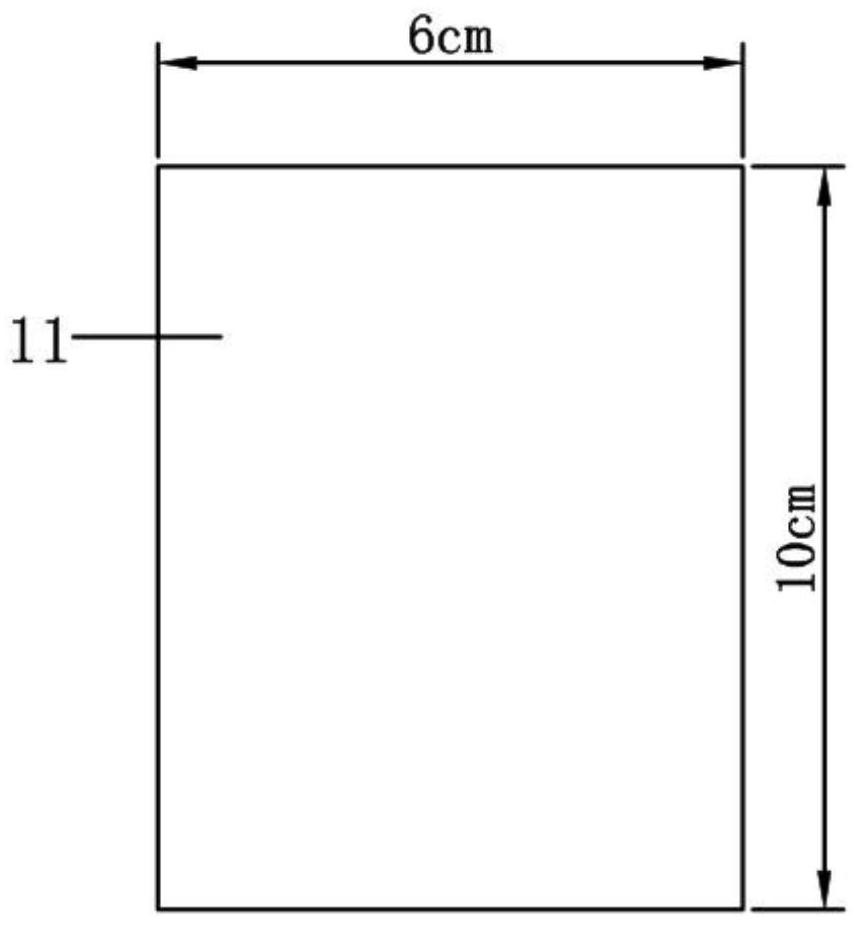

[0035] Such as Figure 1 to Figure 5 As shown, a copper-aluminum integrated current collector electrode includes: a copper-aluminum current collector 1 , a positive electrode material 2 and a negative electrode material 3 . The copper-aluminum current collector 1 includes bonded copper foil 11 and aluminum foil 12 , one side of the copper foil 11 is coated with the negative electrode material 3 , and one side of the aluminum foil 12 is coated with the positive electrode material 2 . The thicknesses of the copper foil 11 and the aluminum foil 12 are 3 μm and 3 μm, or 4 μm and 2 μm respectively, and the length and width of the cross section of the copper-aluminum current collector 1 are 10 cm×6 cm, 20 cm×40 cm or 30 cm×50 cm. In this embodiment, the thicknesses of the copper foil 11 and the aluminum foil 12 are 3 μm and 3 μm respectively, the thickness of the positive electrode material 2 is 80 μm, and the thickness of the negative electrode material 3 is 127 μm.

[0036] The p...

Embodiment 2

[0039] Such as Image 6 As shown, a copper-aluminum integrated current collector laminated battery includes the copper-aluminum integrated current collector electrode described in Embodiment 1, and also includes a separator and an electrolyte 5, and the current collector electrode 4 is stacked in series to form a stack. A separator and an electrolytic solution 5 are provided between the current collector electrode 4 and the current collector electrode 4 .

[0040] The electrolyte includes electrolyte and solvent. The electrolyte is lithium hexafluorophosphate with a concentration of 0.9mol / L. The solvent includes ethylene carbonate and dimethyl carbonate with a weight ratio of 1:1.5. The separator is a polypropylene monolayer microporous membrane.

Embodiment 3

[0042] A preparation process of a copper-aluminum integrated current collector laminated battery, which is used to prepare a copper-aluminum integrated current collector laminated battery described in Example 2, comprising the following steps:

[0043] 1. Prepare copper-aluminum current collector 1, apply adhesive on the surface of copper foil 11 and aluminum foil 12, and roll to form copper-aluminum current collector 1, or directly heat-press composite copper foil 11 and aluminum foil 12 to form copper-aluminum current collector 1. Or use electroplating to plate copper foil 11 on the surface of aluminum foil 12 or plate aluminum foil 12 on the surface of copper foil 11.

[0044] 2. Coating negative electrode material 3 on one side of copper foil 11 and coating positive electrode material 2 on one side of aluminum foil 12 to make current collector electrode 4 .

[0045] 3. The current collector electrodes 4 are cut and then stacked and combined in series to form a stack. A sep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com