Production process of double-glass photovoltaic module

A photovoltaic module and production process technology, applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve problems such as glass breakage, cracking, and self-explosion, and achieve the effects of avoiding breakage, avoiding injury, and good protection and buffering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

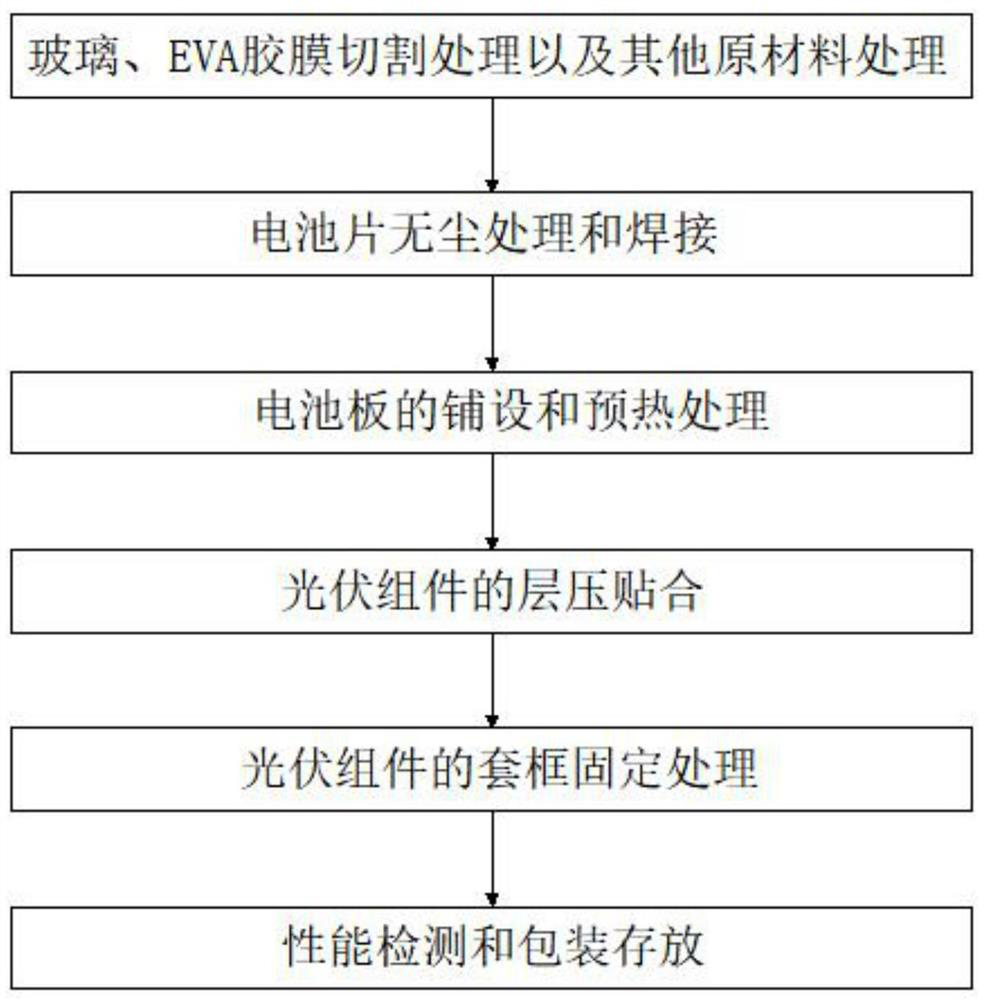

[0023] see figure 1 , the present invention provides a technical solution: a double-glass photovoltaic module production process, comprising the following steps:

[0024] Step 1: Temper the glass. After the treatment, cut the tempered glass into the required size and prepare the EVA film with the same size as the tempered glass. Prepare the welding ribbon, battery sheet and frame for welding and rubber sleeves;

[0025] Step 2: Dedust the toughened glass, batteries, EVA film and other materials, then put the welding materials in the dust-free welding workshop, and then use the preheated welding torch to weld the batteries with welding tape;

[0026] Step 3: Lay the welded battery slices in the mold plate as required, and connect multiple battery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com