An anti-theft aluminum alloy door and window

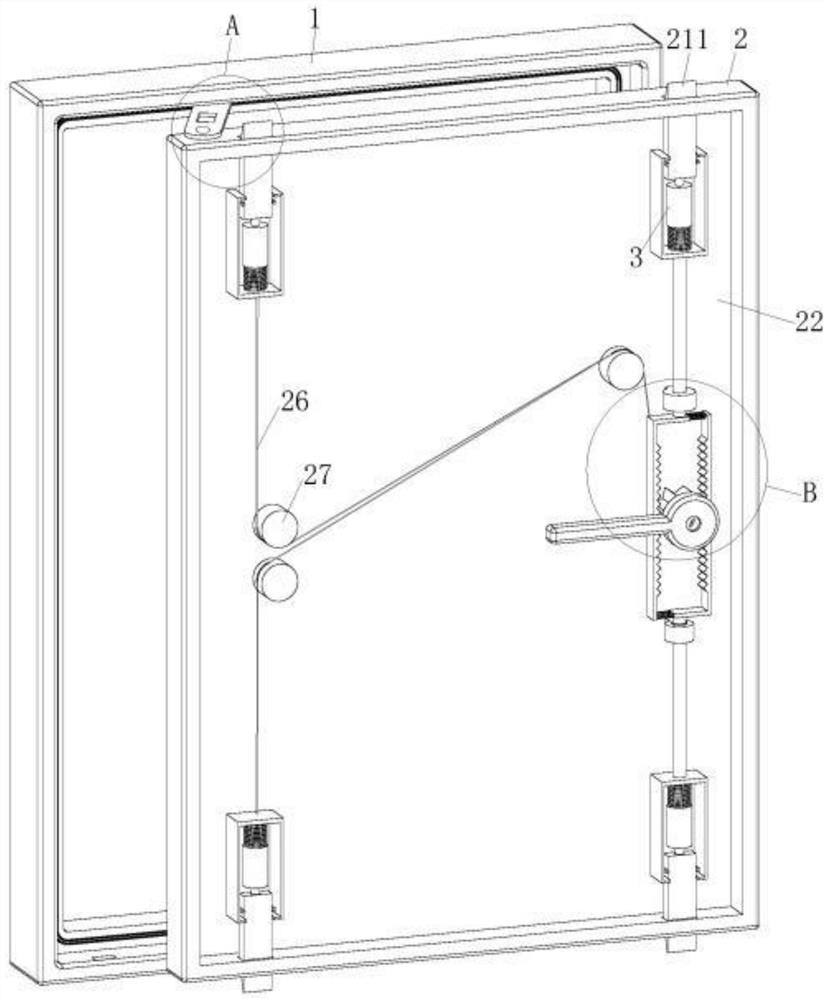

An aluminum alloy door and window, anti-theft technology, applied in the field of doors and windows, can solve the problems of limited door opening angle, single locking position between the door and the door frame, and reduced door safety and anti-theft coefficient, so as to increase circulation, increase flexibility, Addressing space-occupying effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

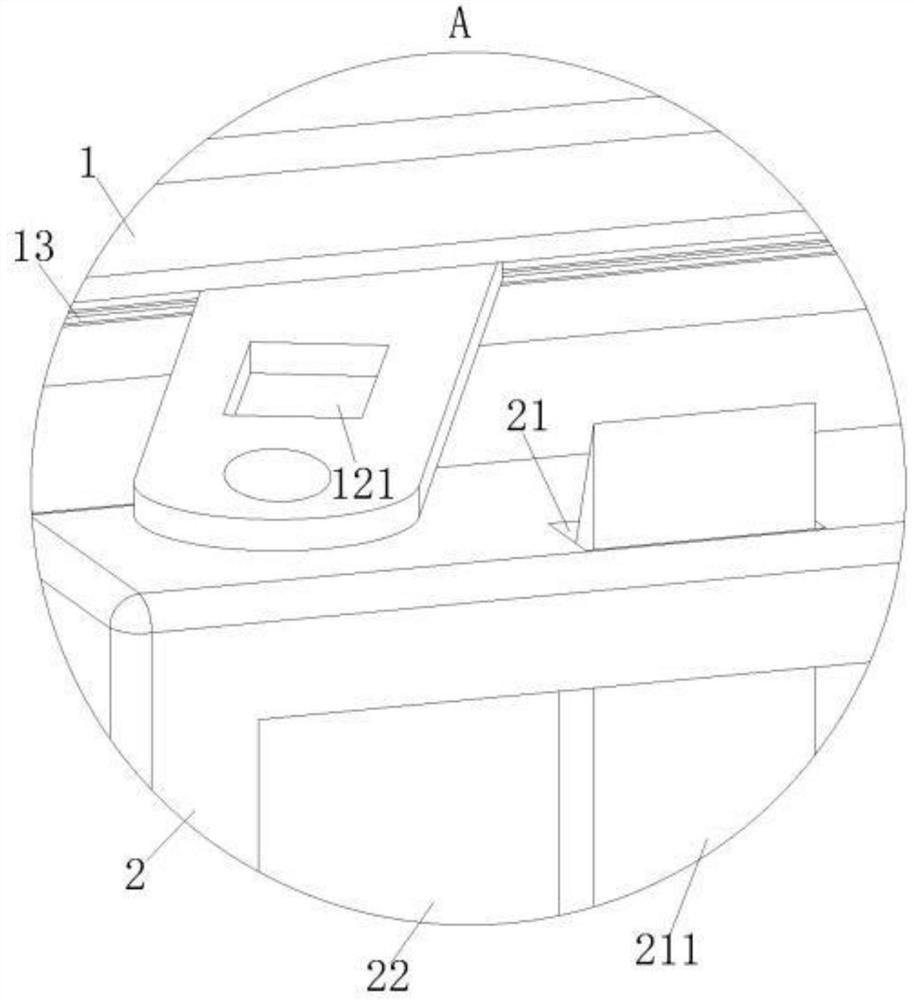

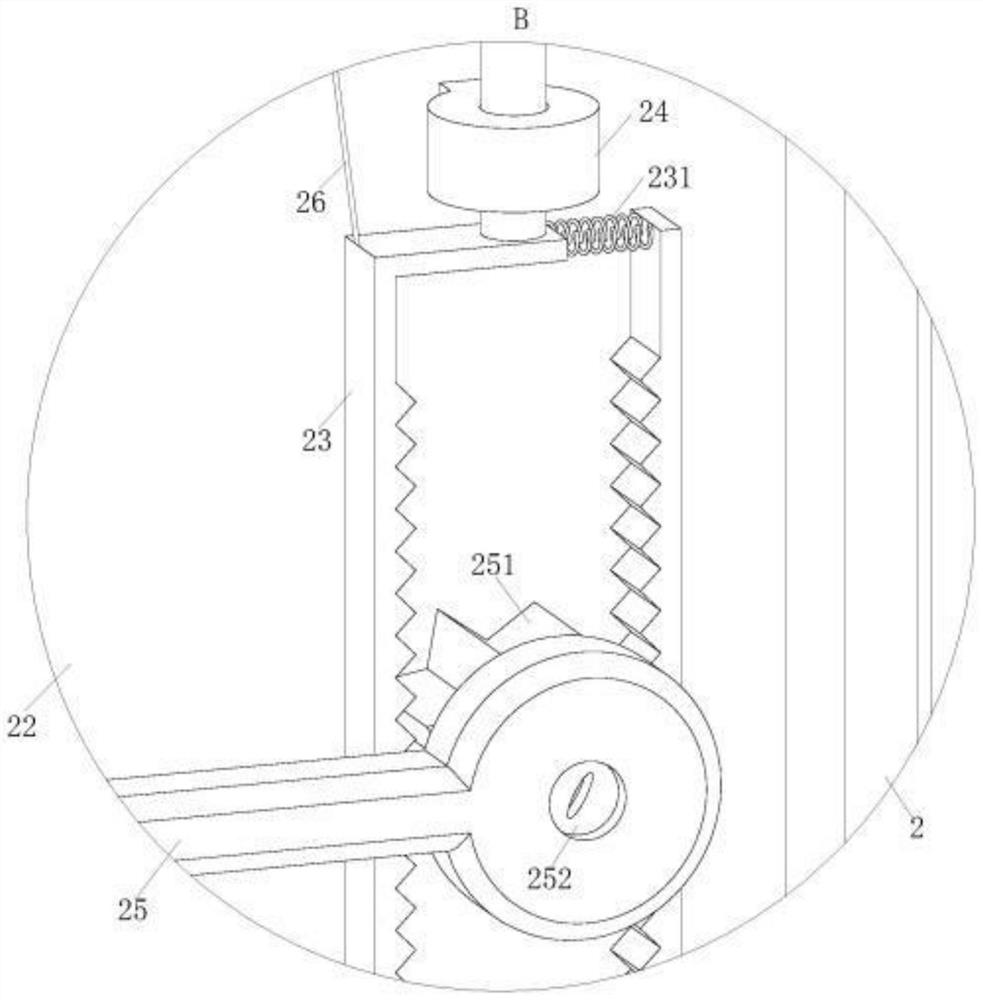

[0024] As a specific embodiment of the present invention, the telescopic unit 3 includes a sleeve 31, a push rod 32, a turntable 33 and a U-shaped block 34; the outer ring of the sleeve 31 is fixed on the side wall of the first cavity 22 , a guide rail 311 is provided symmetrically in the sleeve 31, and the guide rail 311 is embedded in the No. 2 chute 321 provided on the ejector rod 32; The tip on the rod 32 fits the slope on the turntable 33; the lower end of the turntable 33 is connected to the U-shaped block 34 through the second spring 331, and the upper end of the U-shaped block 34 is buckled on the stopper 212 provided on the clamping block 211 ; Through the cooperation between the telescopic unit 3 and the clamping block 211, the clamping block 211 is snapped into the No. 1 slot 11, and the clamping block 211 is retracted into the No. 1 through hole 21; when working, the working of the telescopic unit 3 The principle is the same as the working principle of pressing the...

specific Embodiment approach

[0026] As a specific embodiment of the present invention, No. 2 through hole 121 is provided on the No. 1 plate 12, and when the door 2 is attached to the door frame 1, No. 1 groove 11 communicates with No. 2 through hole 121; hole 121, to further fasten the gap between the door 2 and the door frame 1; when working, if the clamping block 211 works for a long time, there will be a gap between the clamping block 211 and the No. 1 slot 11, resulting in a gap between the door 2 and the door frame 1 Loose phenomenon occurs between the door 2 and the door frame 1. When the door 2 and the door frame 1 are attached, that is, the door 2 is in the closed state. At this time, the second through hole 121 of the first plate 12 and the first groove 11 connected, and then the clamping block 211 extends into the first slot 11 through the second through hole 121, the clamping block 211 secures the first plate 12 on the door frame 1, and the first plate 12 fastens the door 2 in the door frame 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com