Method and device for determining reference position of steel belt

A technology of reference position and determination method, which is applied to measurement devices, optical devices, color measurement devices, etc., can solve problems such as inconsistent punching positions, equipment operation problems, and inability to operate, and achieve the effect of simple positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] A method for determining a steel strip reference position, comprising:

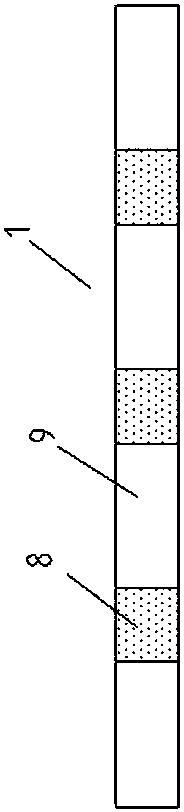

[0023] 1) if figure 1 As shown, a section of the steel strip is heated to the discoloration temperature, and a heated section 8 and a non-heated section 9 are formed on the surface of the steel strip, which have obvious color difference;

[0024] 2) Use the color optical fiber sensor to identify the color difference naturally formed after the steel strip is heated, and determine the annealing position of the steel strip;

[0025] 3) Use this annealing position as the reference point for steel strip length measurement.

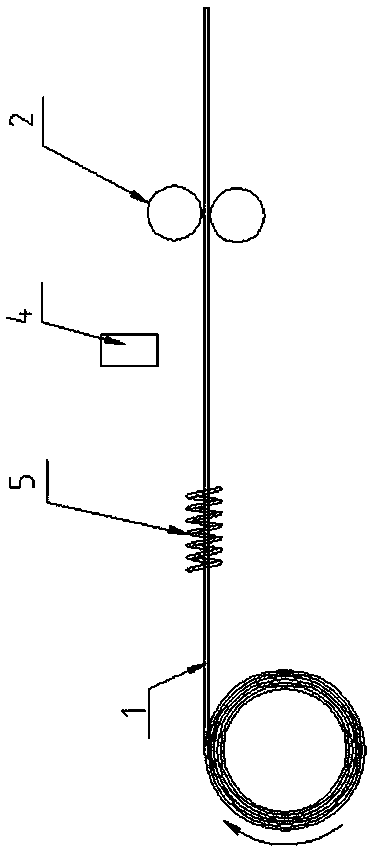

[0026] Correspondingly, a device for determining the reference position of the steel strip is provided, such as figure 2 As shown, it includes a steel strip 1, a transport mechanism 2, a color optical fiber sensor 4, and a controller (not shown in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com