Blade detection method based on line structured light

A line-structured light and detection method technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of high measurement cost and low measurement efficiency, and achieve the effect of reducing errors and data transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

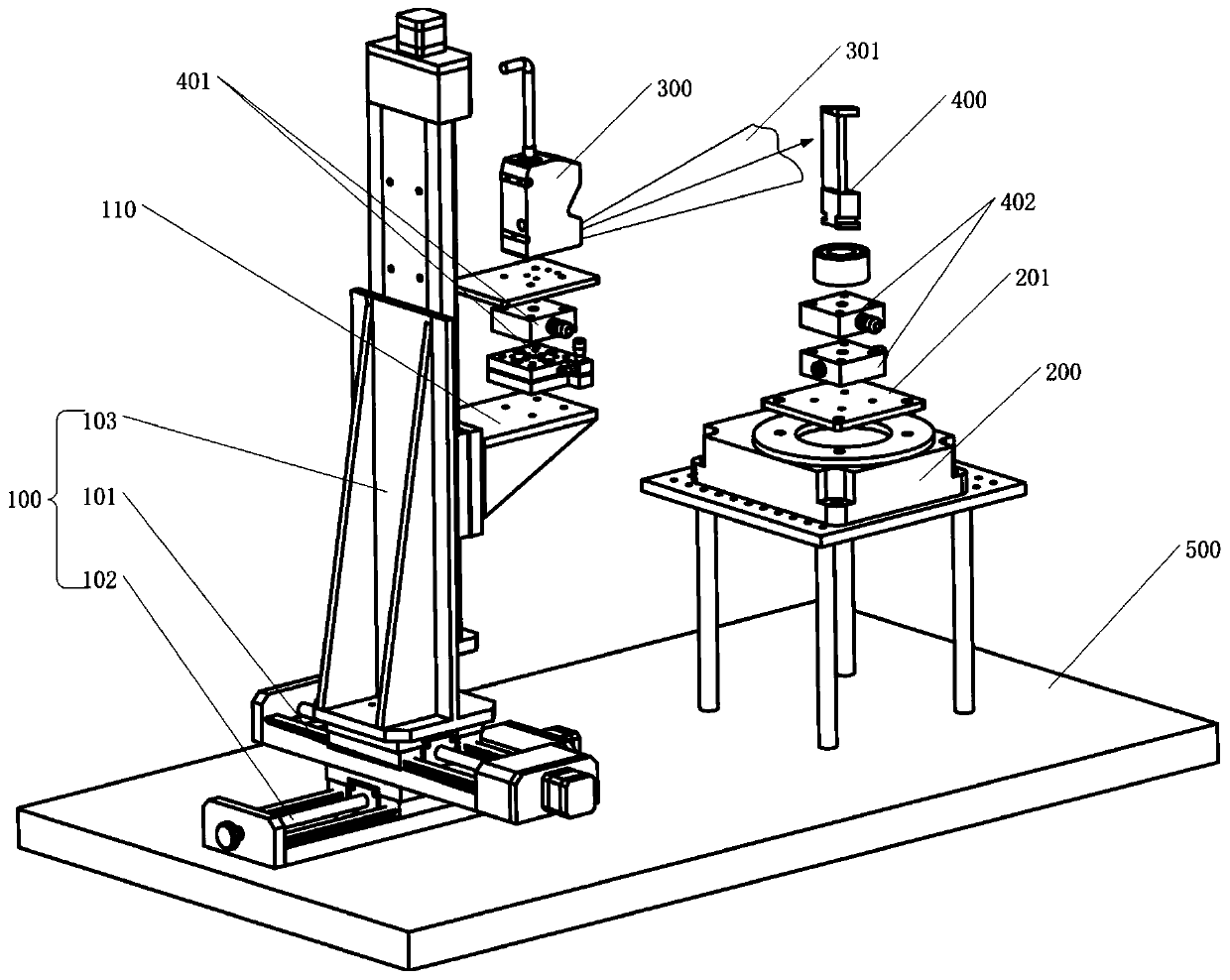

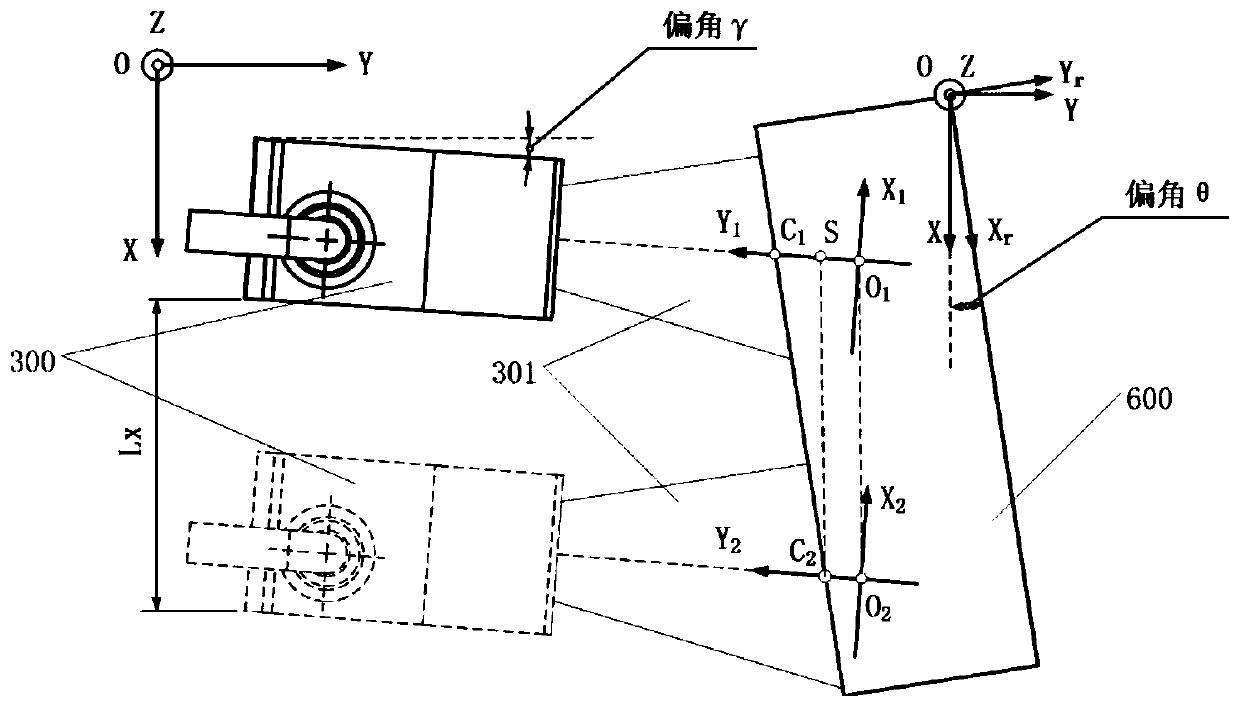

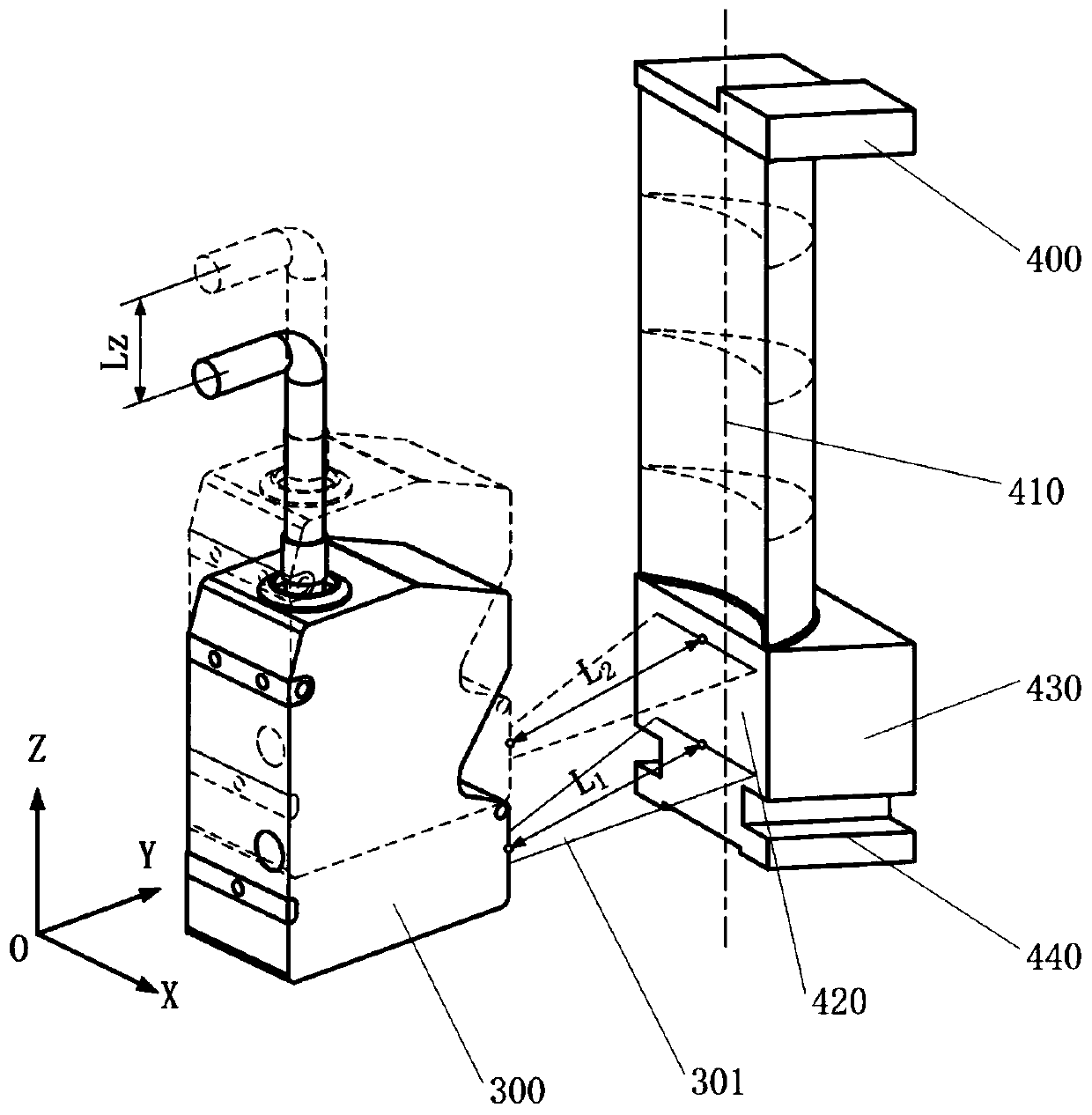

[0053] Such as figure 1 As shown, the detection device required in this embodiment includes a support 100 that can translate along the spatial coordinates X, Y, and Z axes and a turntable 200 that can rotate around its own Z axis. The X, Y, and Z axes of the support 100 And the main movement of the Z-axis 210 of the turntable is three translation components (the support drives the line structured light profiler) and one rotation component (the turntable drives the blade to be measured), so that the distance between the line structured light profiler 300 and the blade to be measured 400 is Generate four-axis relative motion. Specifically, the Y-axis 102 of the bracket 100 is installed on the optical table 500, the X-axis 101 is horizontally and vertically and can be translated on the Y-axis 102, and the Z-axis 103 is vertically and vertically and can be translated on the X-axis 101, Z The axis 103 moves along the vertical direction and is equipped with a mounting plate 110, on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com