Ultrasonic radial bearing friction torque and high-speed operation stability testing device

A technology for stability testing and radial bearings, applied in mechanical bearing testing, measuring devices, force/torque/power measuring instruments, etc., can solve problems such as bearing damage, achieve good real-time performance, and scientific and reasonable structural design and measurement schemes , the effect of strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with embodiment the present invention will be further described.

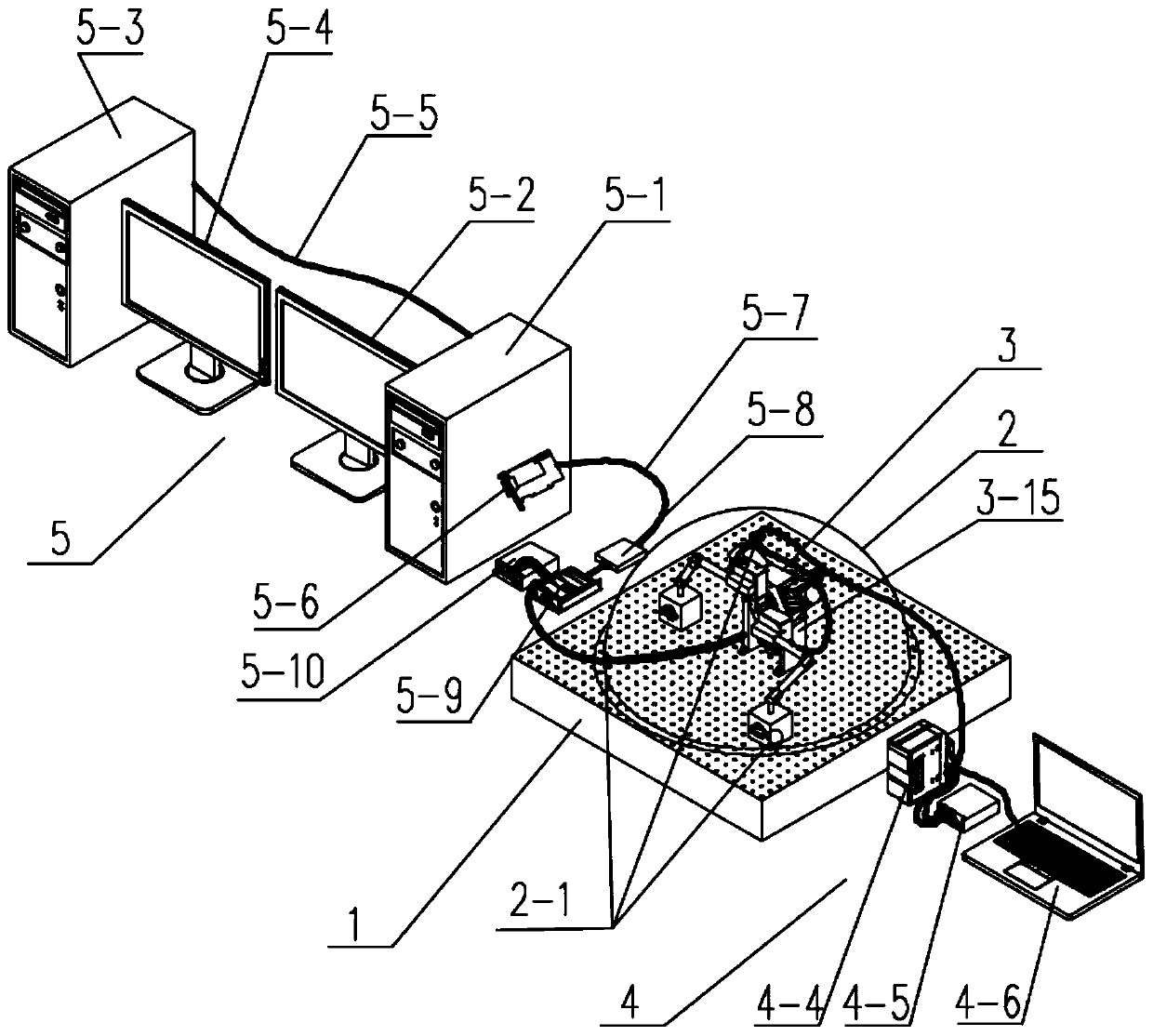

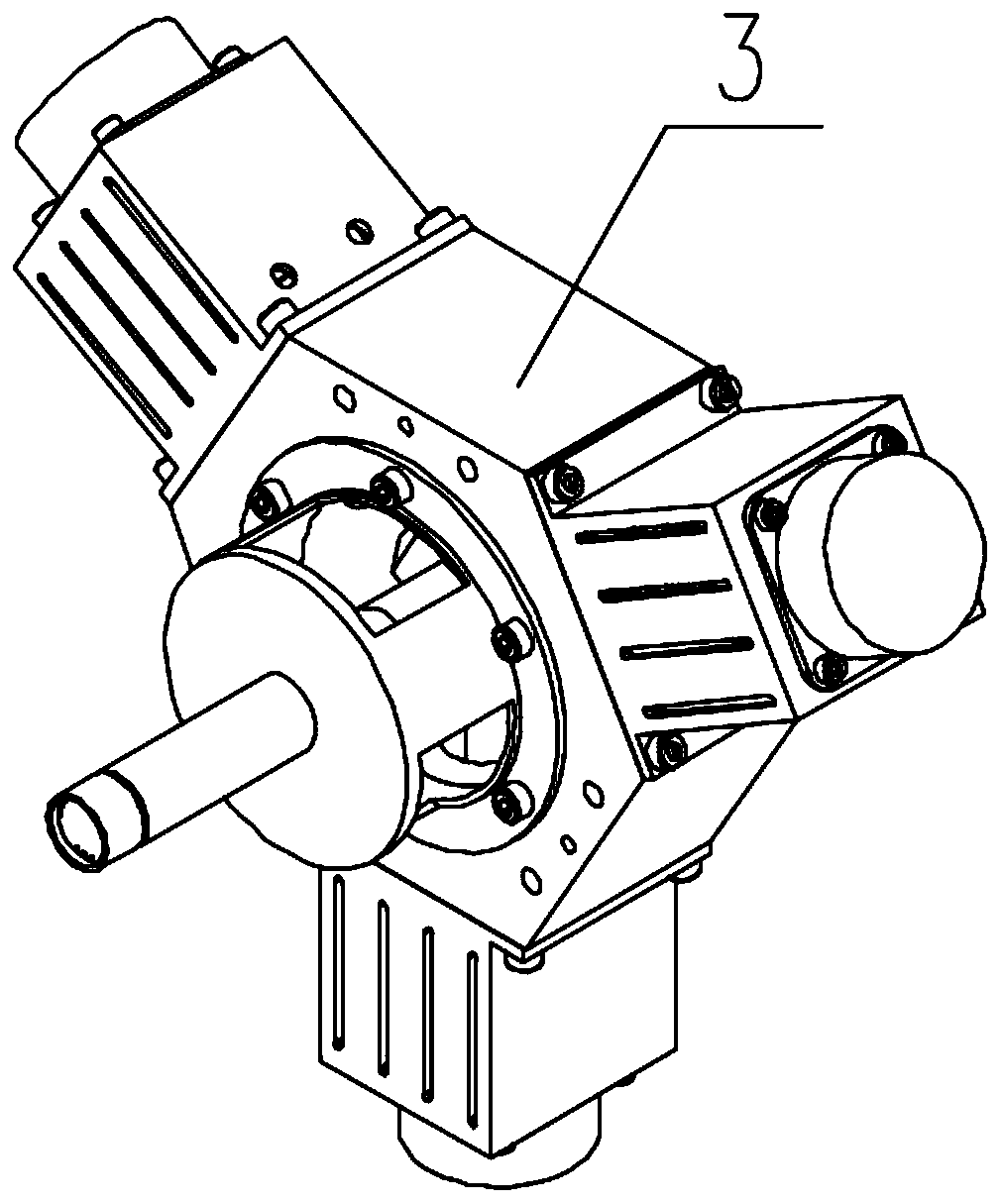

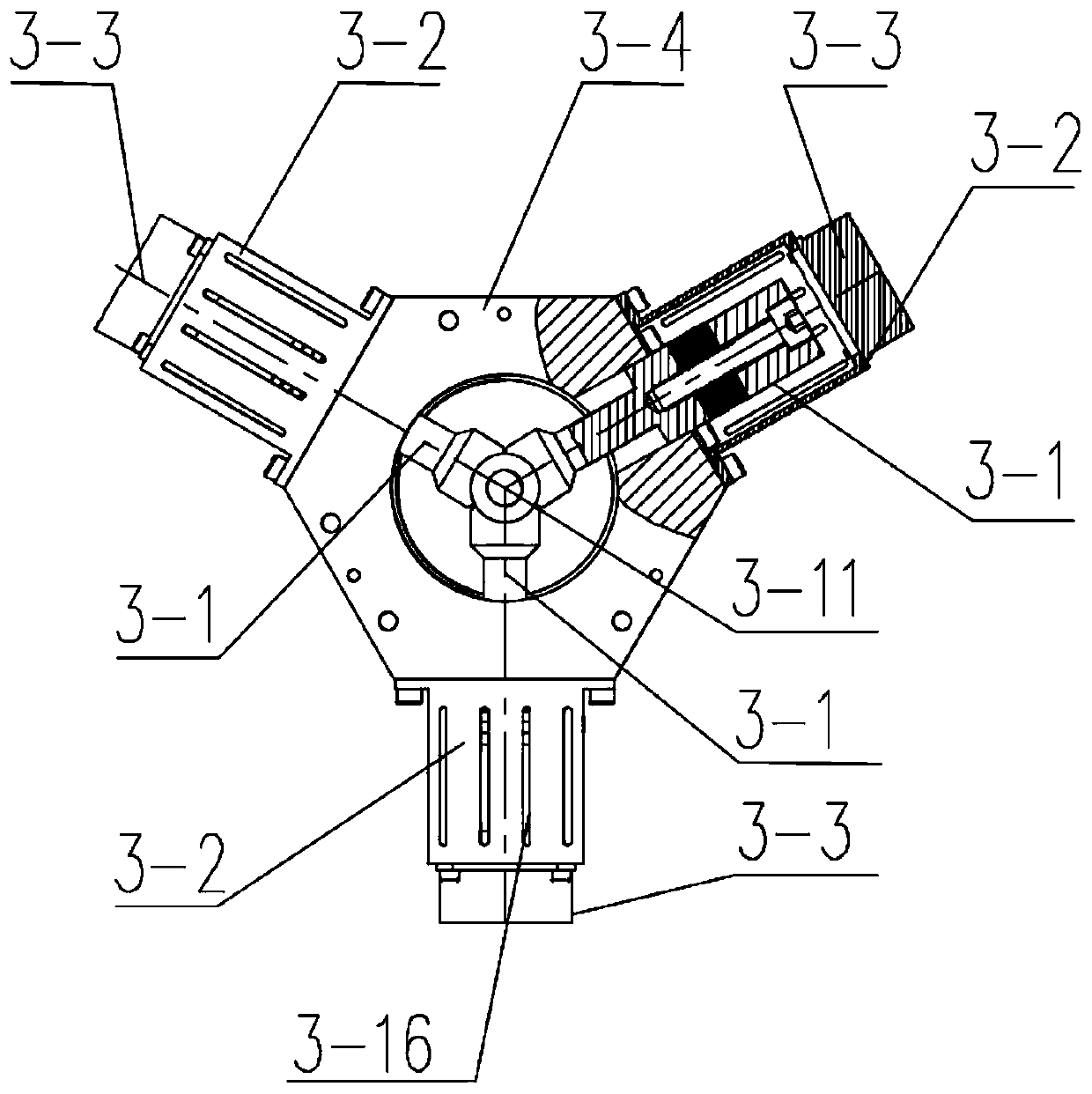

[0033] Such as Figure 1-5 As shown, an ultrasonic radial bearing friction torque and high-speed running stability test device includes a vibration isolation platform 1, an airtight cover 2, a bearing rotor system 3, an axis track measurement system 4 and a data acquisition and control system 5, the The airtight cover 2 covers the bearing rotor system 3 installed on the vibration isolation platform 1,

[0034] The airtight cover 2 is connected to the vibration isolation platform 1 by bolts. According to the wiring design requirements, the airtight cover 2 has an airtight cover outlet hole 2-1 at the top and near the installation plane, and the laser displacement sensor 4- 1, the power supply line of the motor 3-13, and the connecting wire of the motor driver 5-9 pass through the outlet hole 2-1 of the airtight cover; for the convenience of observation and to ensure a certain strengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com