A segmental test piece structure of hyperbaric chamber type main combustion chamber

A technology of the main combustion chamber and hyperbaric chamber, which is applied in the field of aero-engines, can solve the problems affecting the test safety and the life of the test piece, affecting the flow distribution of the test piece, and difficult to meet the strength design requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

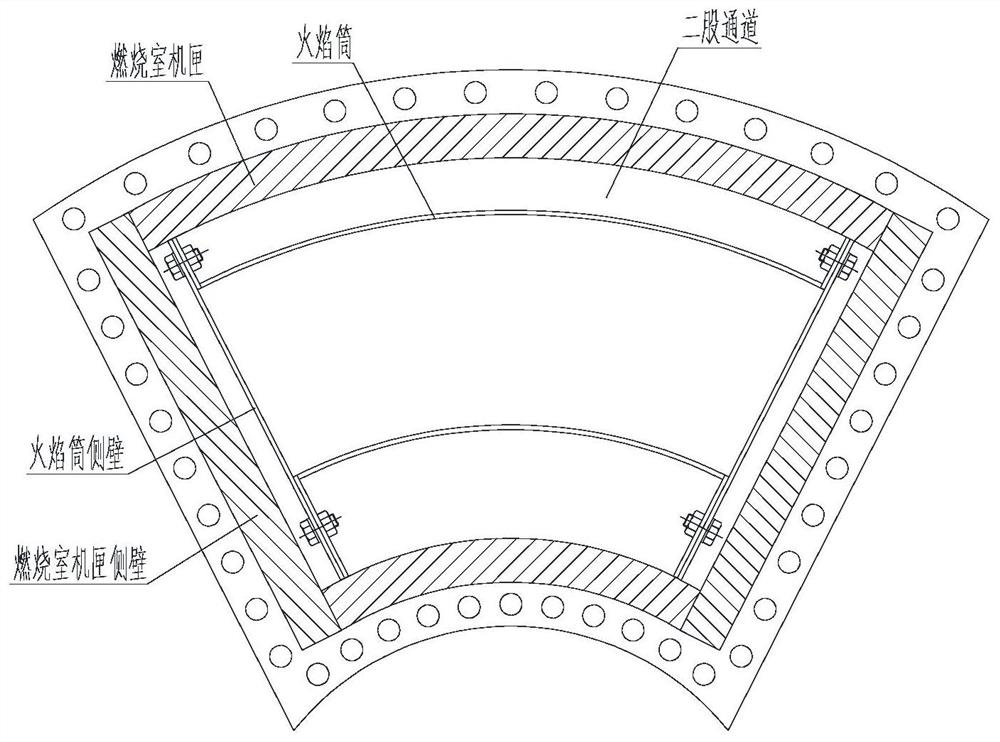

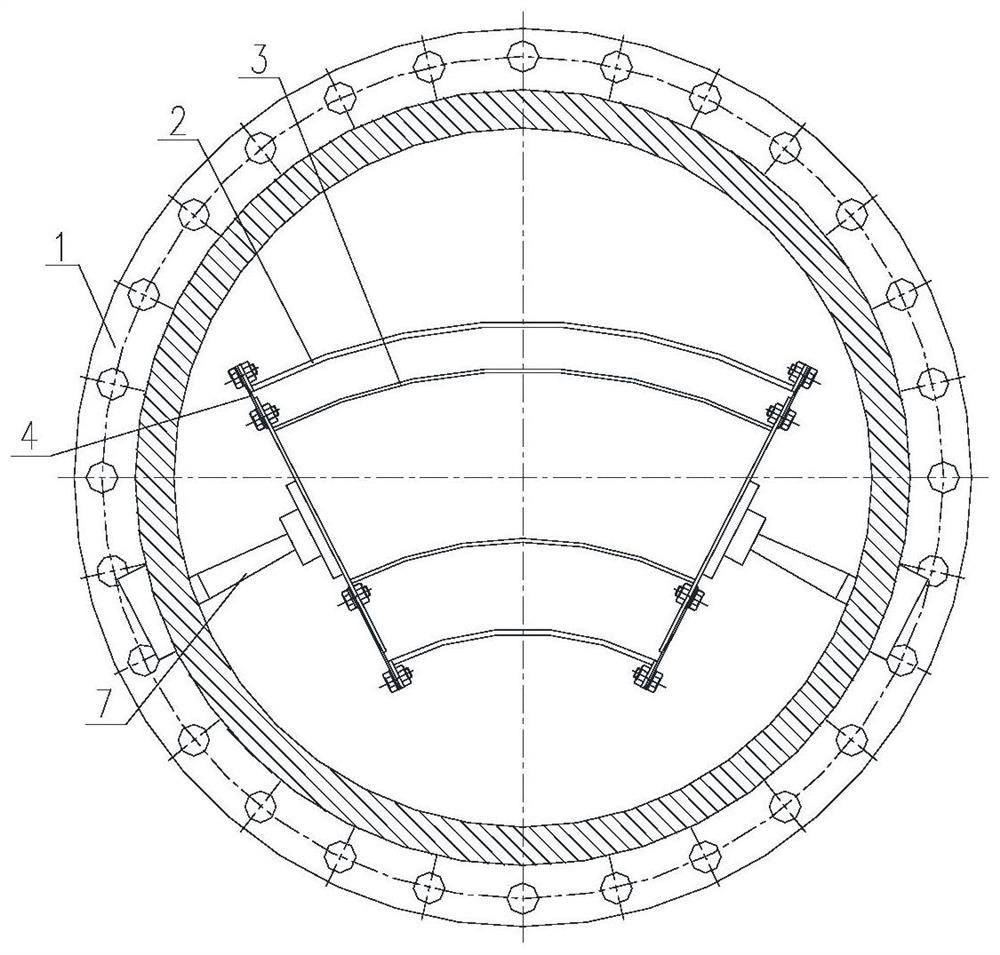

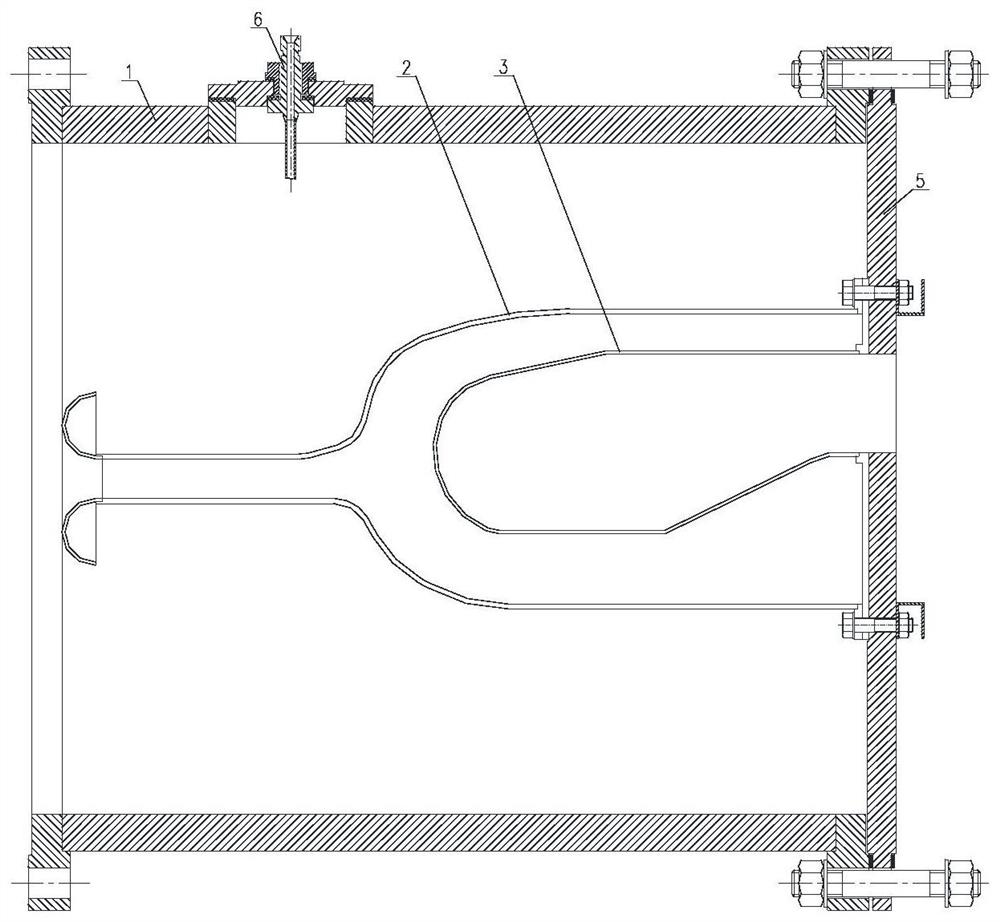

[0031] The present invention is a fan-shaped test piece structure of a hyperbaric chamber type main combustion chamber, which mainly consists of a load-bearing casing 1, a fan-shaped casing 2, a fan-shaped flame cylinder 3, a sealing side wall 4, a supporting flange 5, a fuel nozzle 6, and auxiliary supports. 7 components, simple and reliable structure, has a certain degree of versatility, and is suitable for high temperature and high pressure component test pieces.

[0032] The sealing side wall 4 is pressed and sealed by bolts to seal the side walls of the fan-shaped casing 2 and the fan-shaped flame tube 3 to form a closed secondary channel of the main combustion chamber, and has the ability to compensate for processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com