A large-diameter optical cable direct-buried construction vehicle

A direct-buried, large-diameter technology, applied in the field of telecommunications engineering, can solve problems such as excessive resource occupation and backfilling, and achieve the effect of improving work efficiency and reducing labor force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

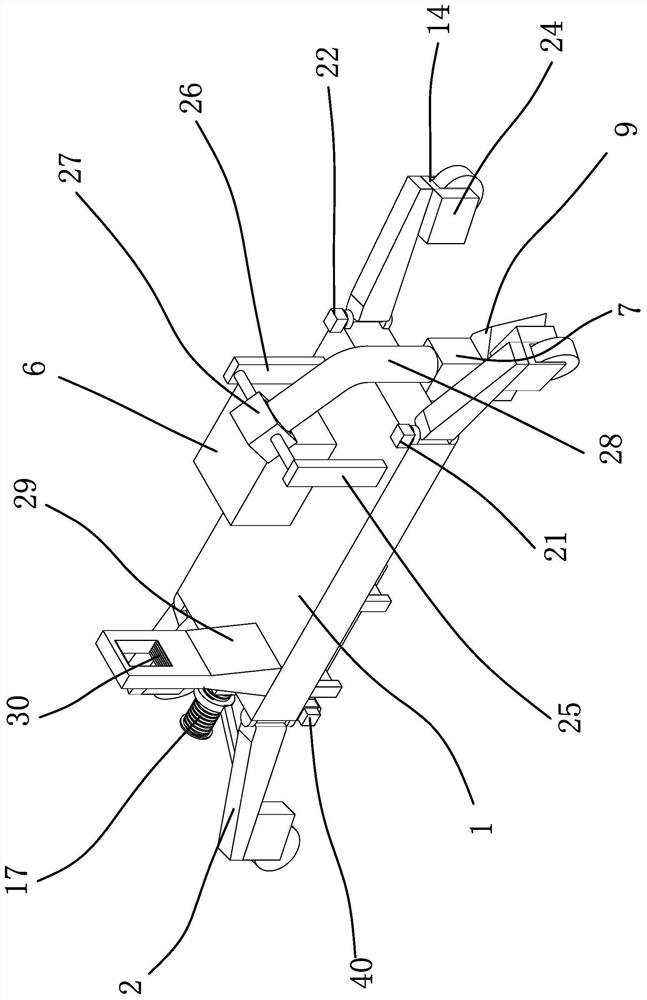

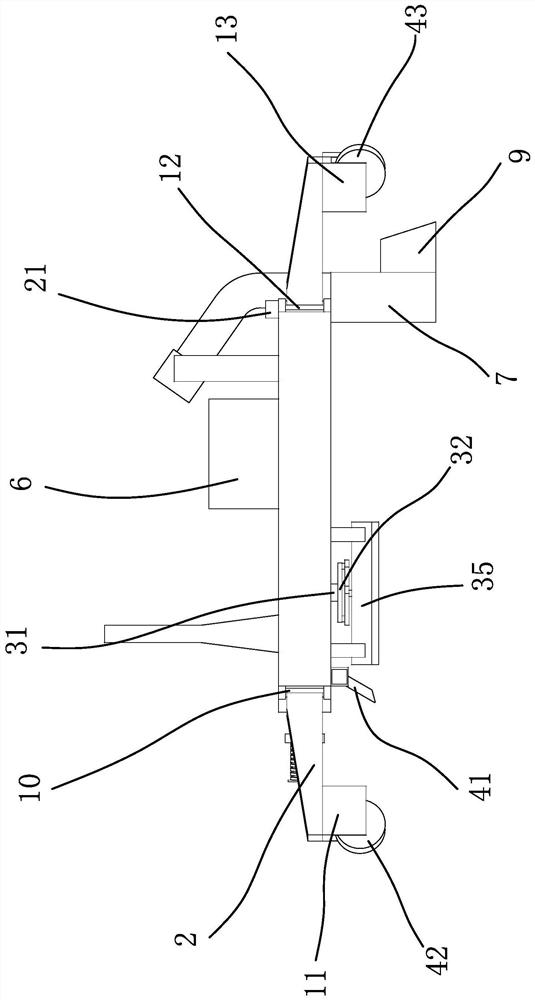

[0028] Such as figure 1 and figure 2 As shown, a large-diameter optical cable direct-buried laying construction vehicle includes a car body 1 and a driver's cab 6, and the car body 1 is hinged with support one 2, support two 3, support three 4 and support four 5, support one 2, Support two 3, support three 4, support four 5 are respectively provided with wheel one 42, wheel two, wheel three 43, wheel four; The lead through hole 8 is welded with a ditching coulter 9 on one side of the lead plate 7 .

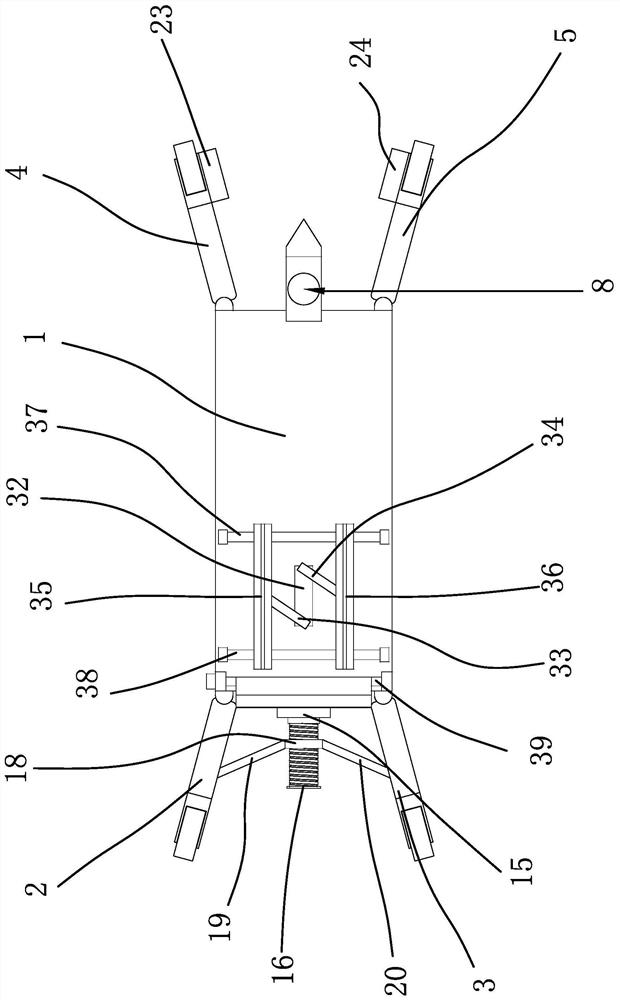

[0029] Such as image 3 As shown, the lower surface of the car body 1 is provided with a preliminary backfill device, and the preliminary backfill device is located on the side facing away from the edge of the ditching coult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com