Chip surface metal residue and contamination cleaning method

A surface metal and cleaning method technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as metal residue, chip misjudgment, failure to find the real cause of failure, etc., to accelerate volatilization, improve success rate, easy to find effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

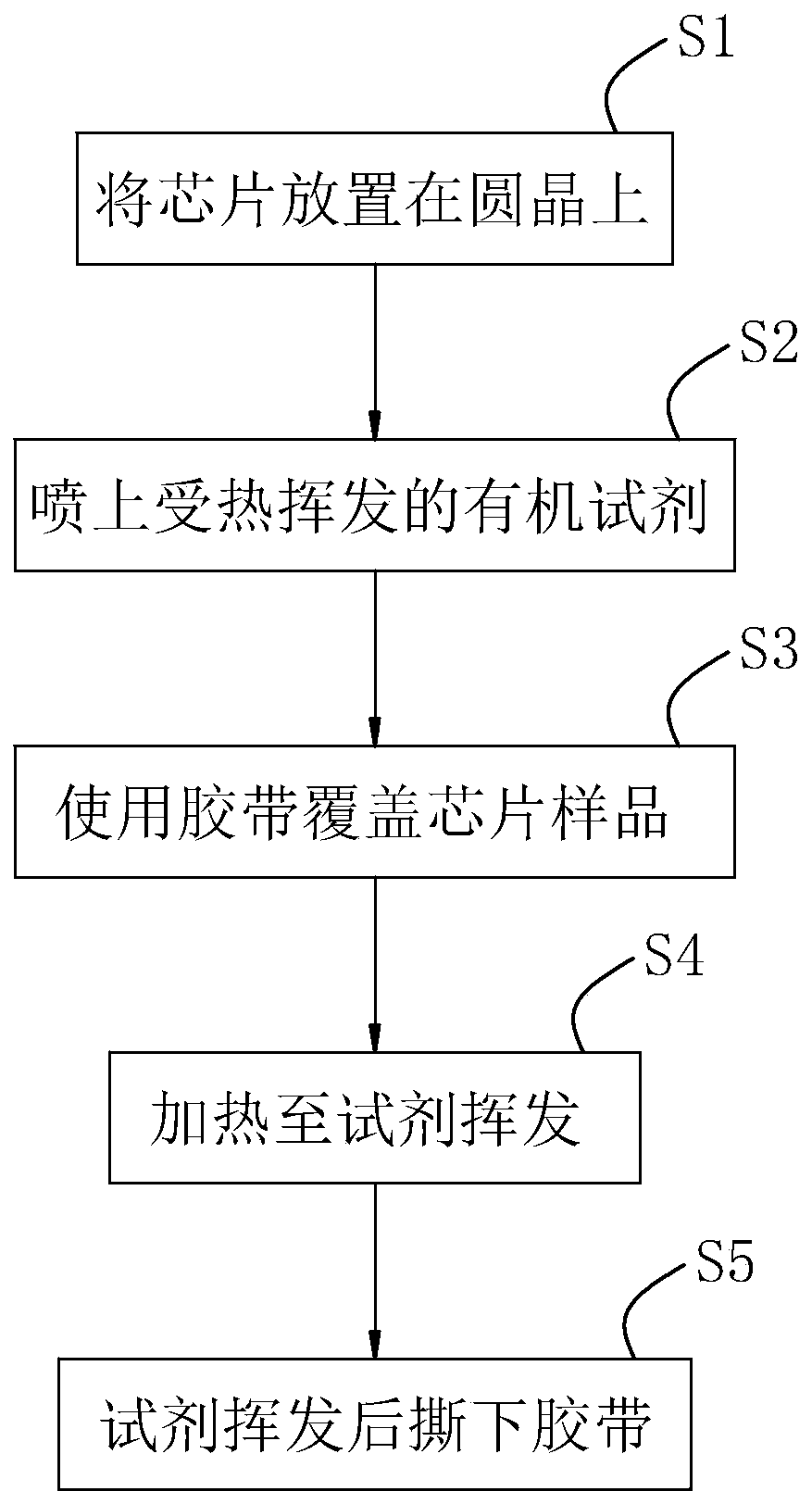

[0041] A method for cleaning metal residue and contamination on the surface of a chip, such as figure 1 shown, including the following steps:

[0042] S1: Place the chip on the wafer. Before placing the chip, use a spray gun to spray a layer of organic reagent from the side. The organic reagent can be ethanol or carbon tetrachloride. The design of spraying from the side can wash away some impurities.

[0043] S2: Spray the organic reagent volatilized by heating. After the organic reagent is sprayed, it will fill the surface of the chip and form tension sides at the corners of the chip. After the tension side is formed, the side of the chip can be prevented from being covered by the organic reagent, and at the same time, the position of the chip on the chemical reagent can be stabilized, and the organic reagent on one side will not be squeezed away ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com