Static contact and switch cabinet using static contact

A technology of static contacts and contacts, applied in the direction of pull-out switch cabinets, switchgear, switchgear components, etc., can solve the problems of high cost of static contacts, easy to loosen, unable to meet installation conditions, etc., and save materials. Cost, the effect of increasing the conductive area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

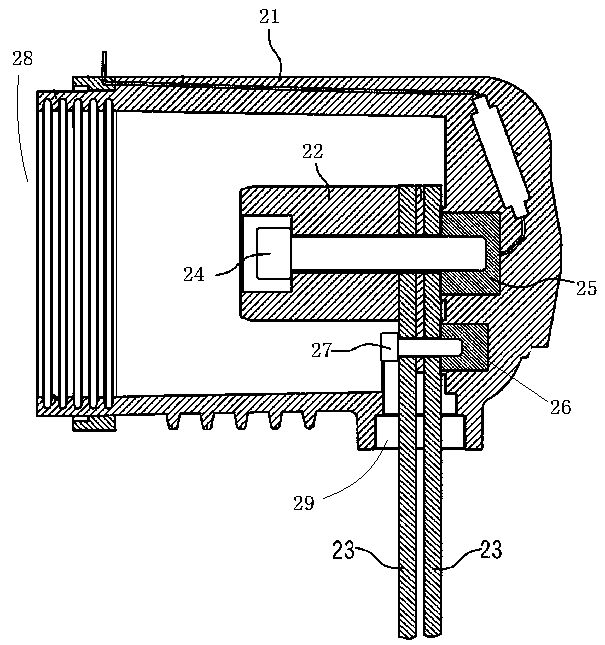

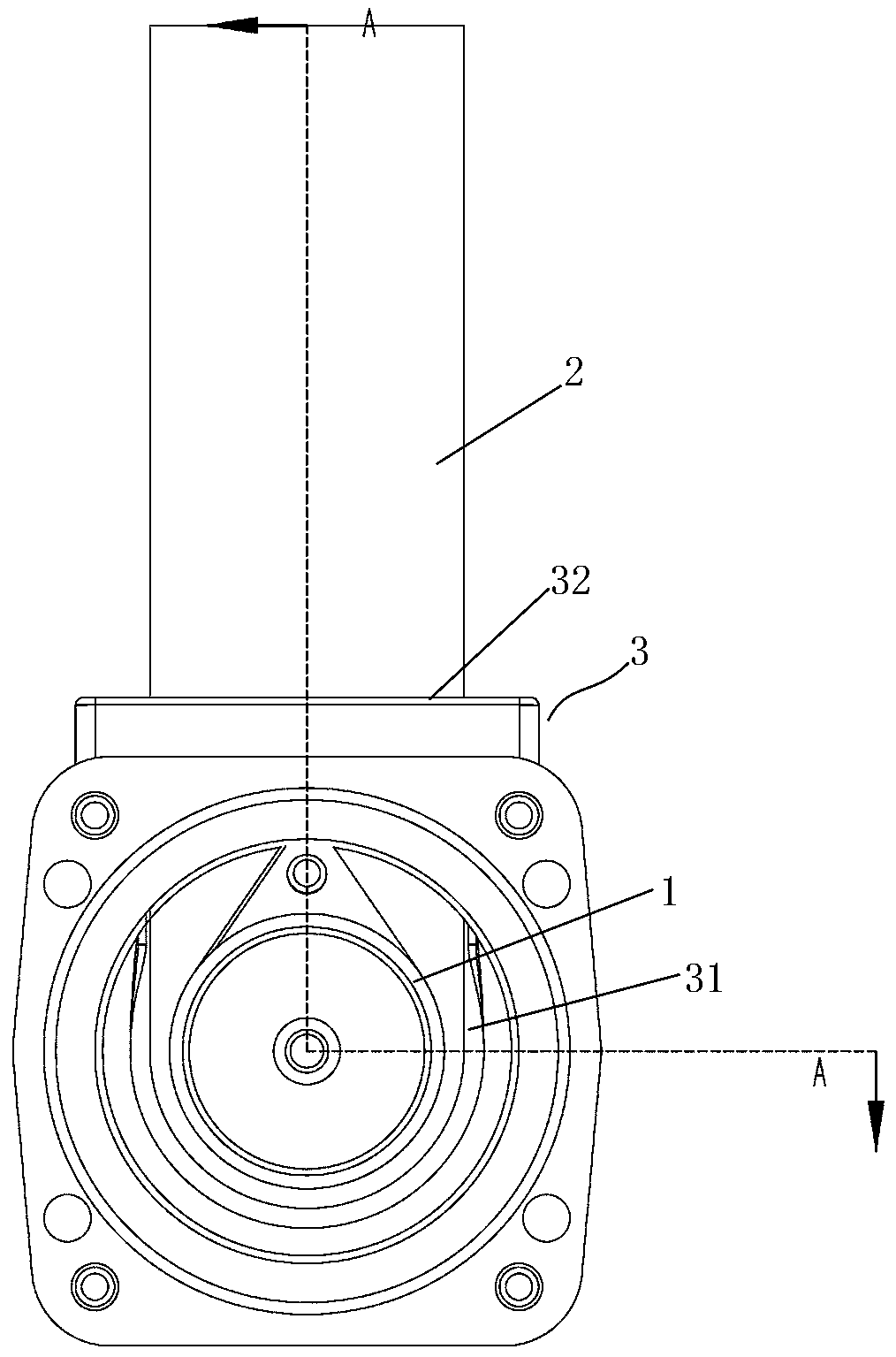

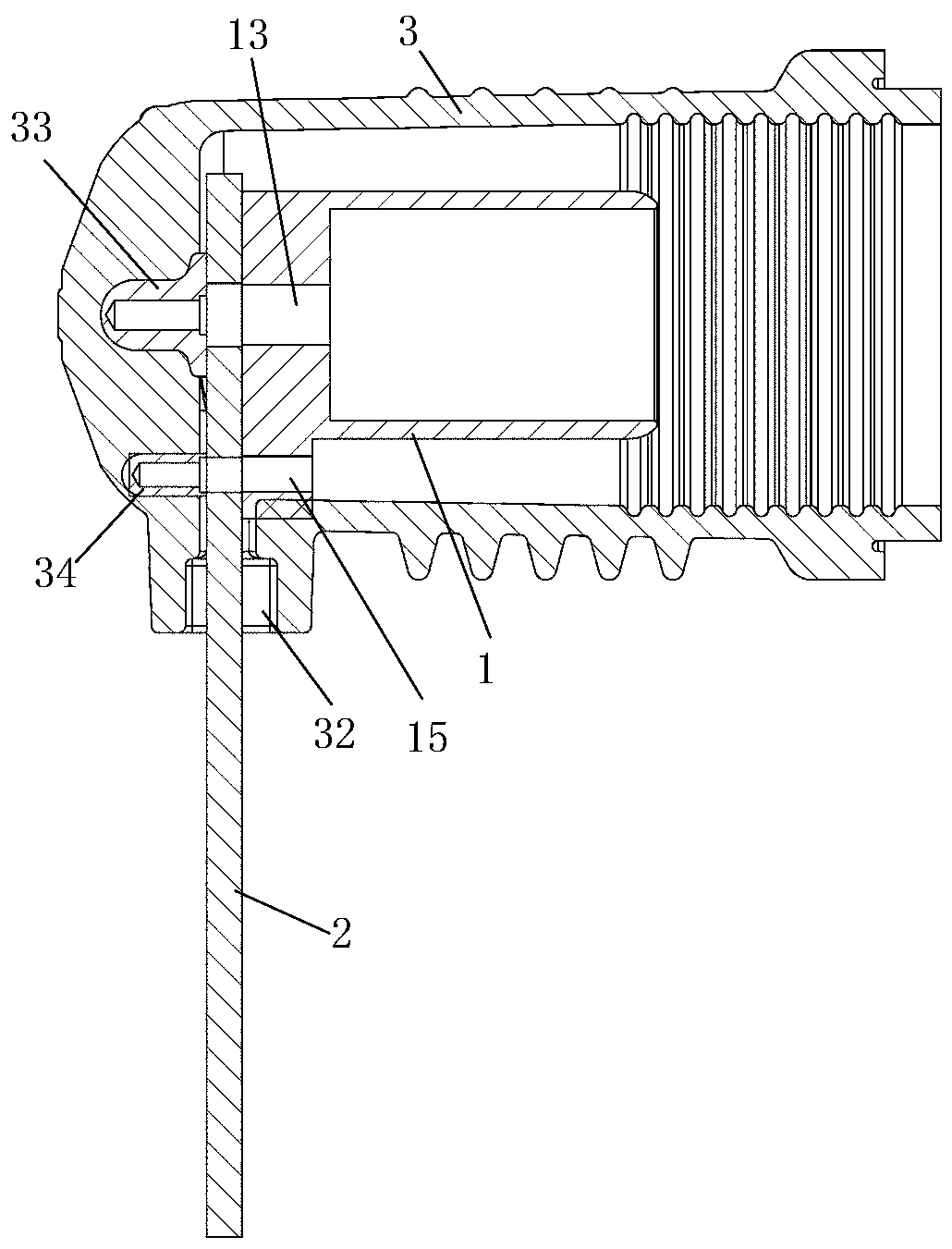

[0043] Specific embodiment 1 of switchgear of the present invention: as Figure 2-9 As shown, the switchgear in this embodiment is a handcart type switchgear, and the switchgear includes a circuit breaker handcart, a static contact 1 , a busbar 2 and a contact box 3 . The static contact 1 is fixed in the contact box 3, the main contact of the circuit breaker trolley can be inserted into the contact box 3, and electrically connected with the static contact 1 in the contact box 3, and one end of the busbar 2 is extended into the The inside of the contact box 3 is conductively connected with the static contact 1 .

[0044] The contact box 3 is an insulating cylinder whose axis extends along the front-to-back direction, and the front end is open and the rear end is closed. The static contact 1 is fixedly installed in the contact box 3; the front opening of the contact box 3 constitutes a circuit breaker hand The main contact of the car is inserted into the contact insertion port ...

Embodiment 2

[0052] Embodiment 2 of the switchgear of the present invention is different from Embodiment 1 in that: the connecting ear plate is welded and fixed to the contact body.

Embodiment 3

[0053] Embodiment 3 of the switchgear of the present invention differs from Embodiment 1 in that the shape of the connecting ear plate is semicircular; in other embodiments, it may also be oval.

[0054] Embodiment 4 of the switchgear of the present invention is different from Embodiment 1 in that the width of the connecting ear plate from the first end to the second end remains unchanged, and at this time, the dimensions of the inner support plate and the outer support plate can be equal , or the radial size of the inner support plate is larger than the size of the outer support plate.

[0055] In the embodiment of the static contact of the present invention, the structure of the static contact is the same as that of the above-mentioned static contact, and will not be repeated here to avoid repetition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com